Method for measuring flow controlling particle density under simulated real reservoir conditions

A particle density and oil reservoir technology, applied in the direction of measuring devices, particle suspension analysis, suspension and porous material analysis, etc., can solve the problems of short particle migration distance, test particle density, and inability to meet construction needs, etc., to achieve improved results , Guarantee the effect of construction success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

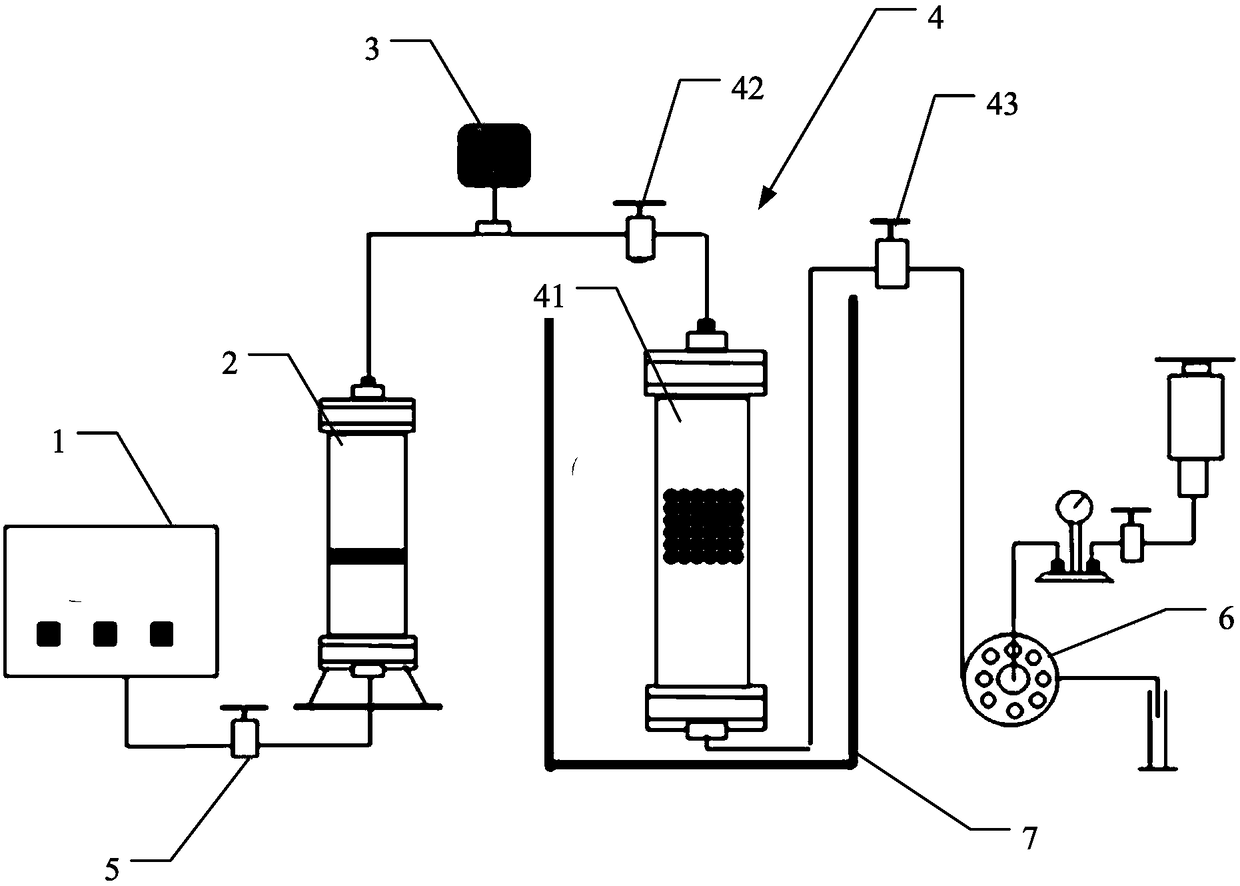

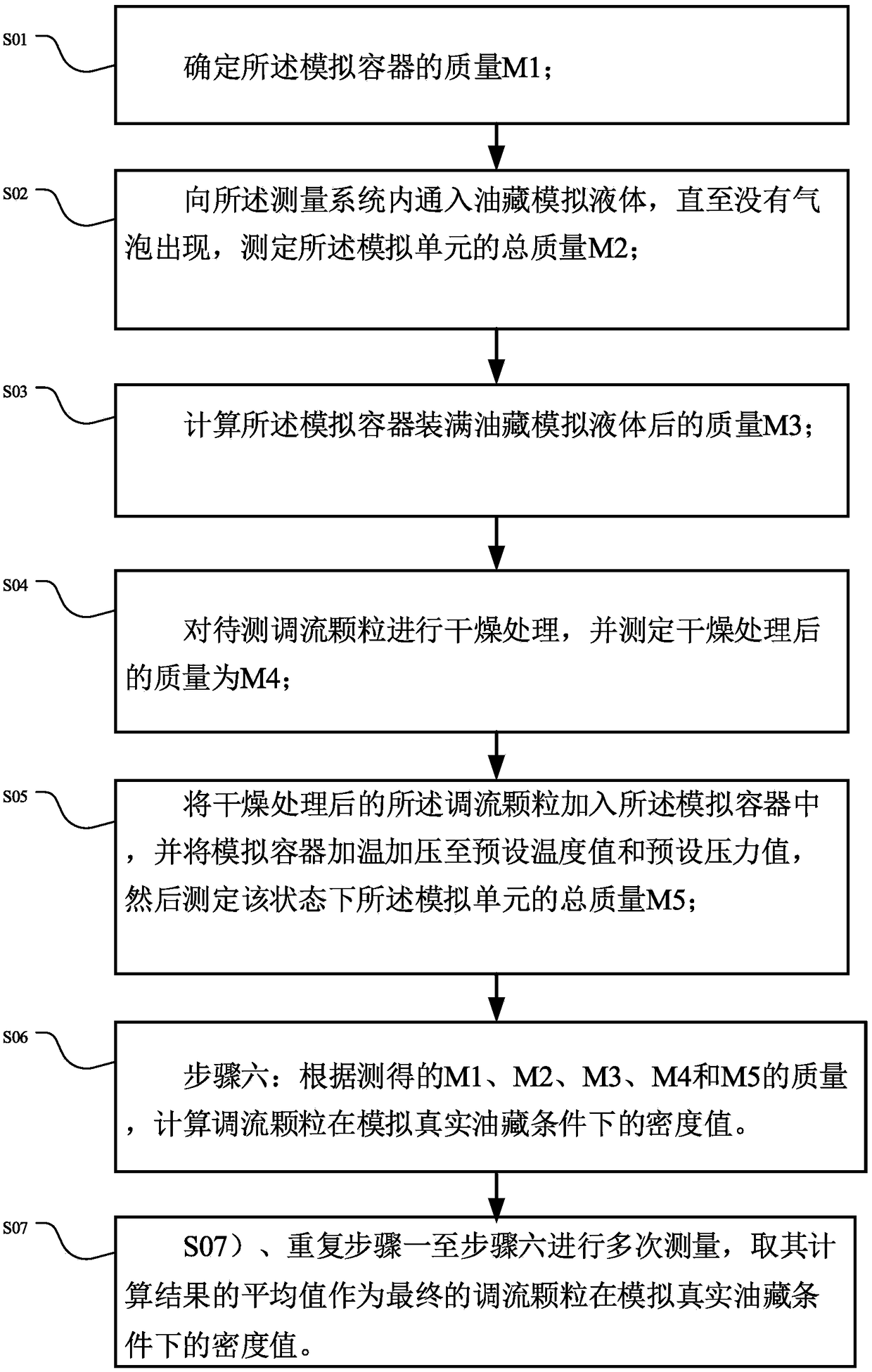

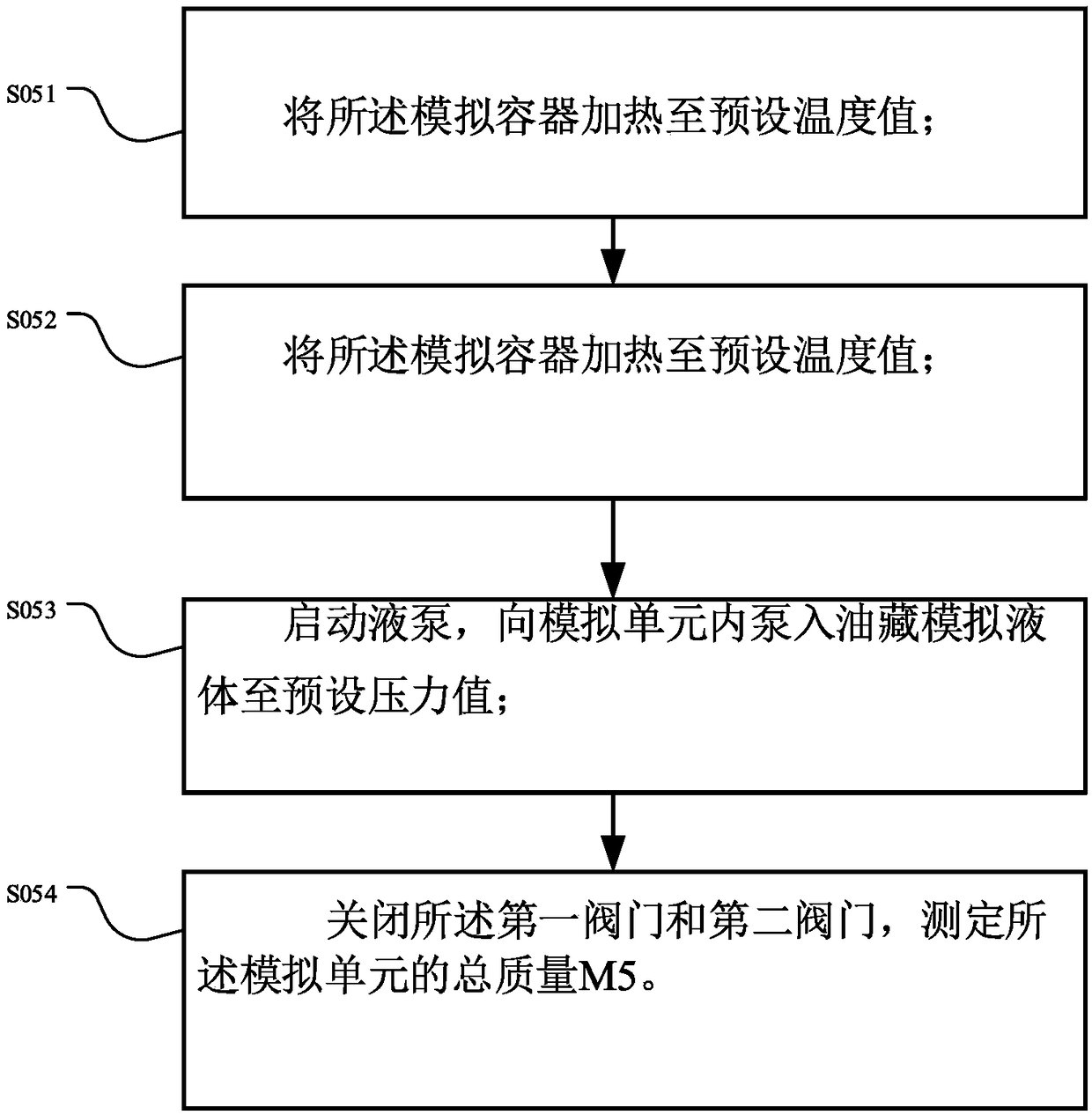

[0039] figure 1 A schematic structural diagram of a measurement system for measuring the density of flow-regulating particles under simulated real reservoir conditions is shown according to an embodiment of the present invention. Such as figure 1 As shown, the measurement system includes a liquid pump 1 , a piston container 2 and a simulation unit 4 , the liquid pump 1 is connected to the liquid inlet of the piston container 2 , and the liquid outlet of the piston container 2 is connected to the simulation unit 4 . The simulation unit 4 includes a simulation container 41 for containing reservoir simulation liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com