Universal clamp for visual inspection of curved glass and detection method

A curved glass and visual inspection technology, which is applied in the field of visual inspection, can solve the problems of affecting the imaging effect, less curved glass, and missed detection of defects, etc., and achieve the effect of improving versatility, simple pressure relief operation, and realizing automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

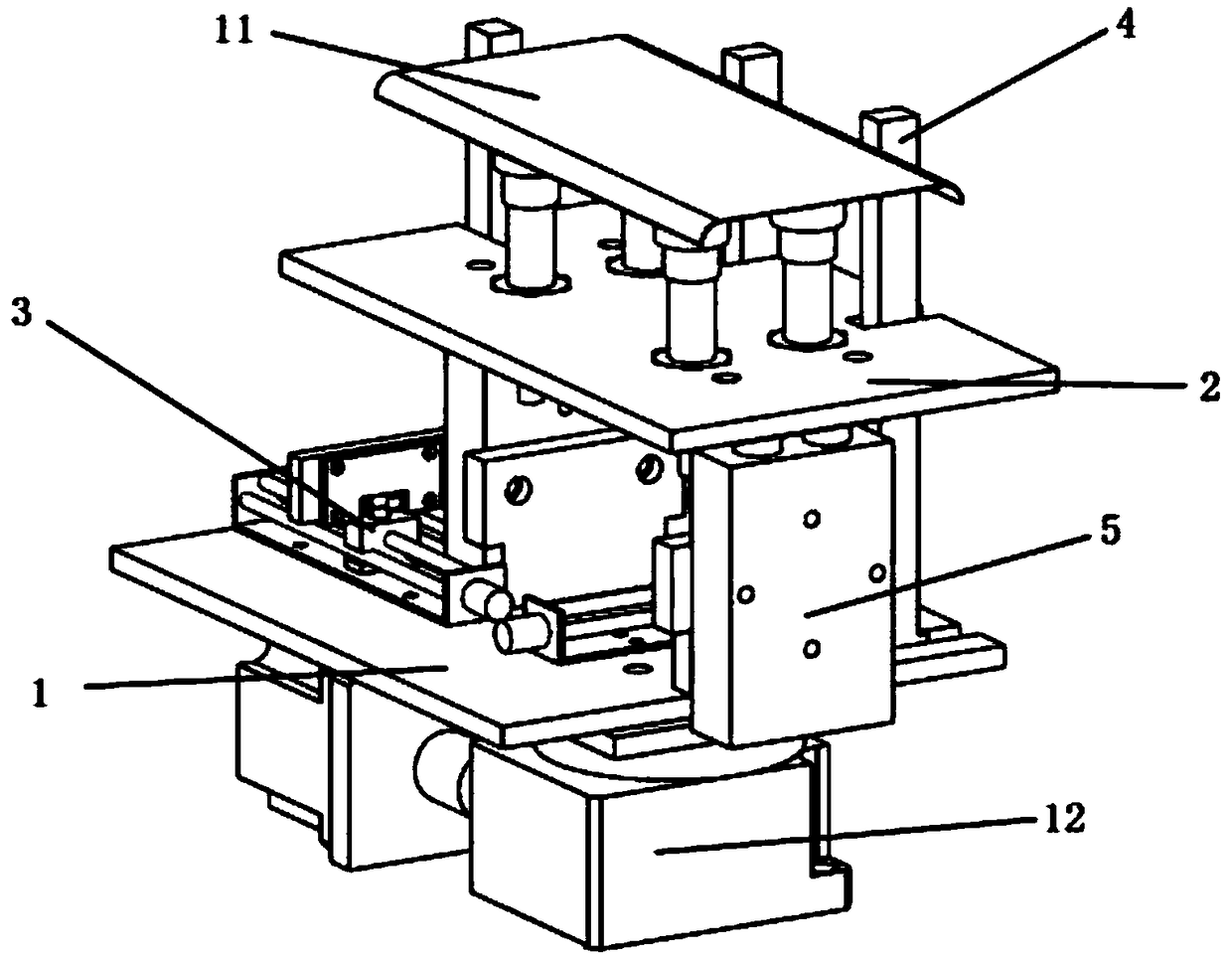

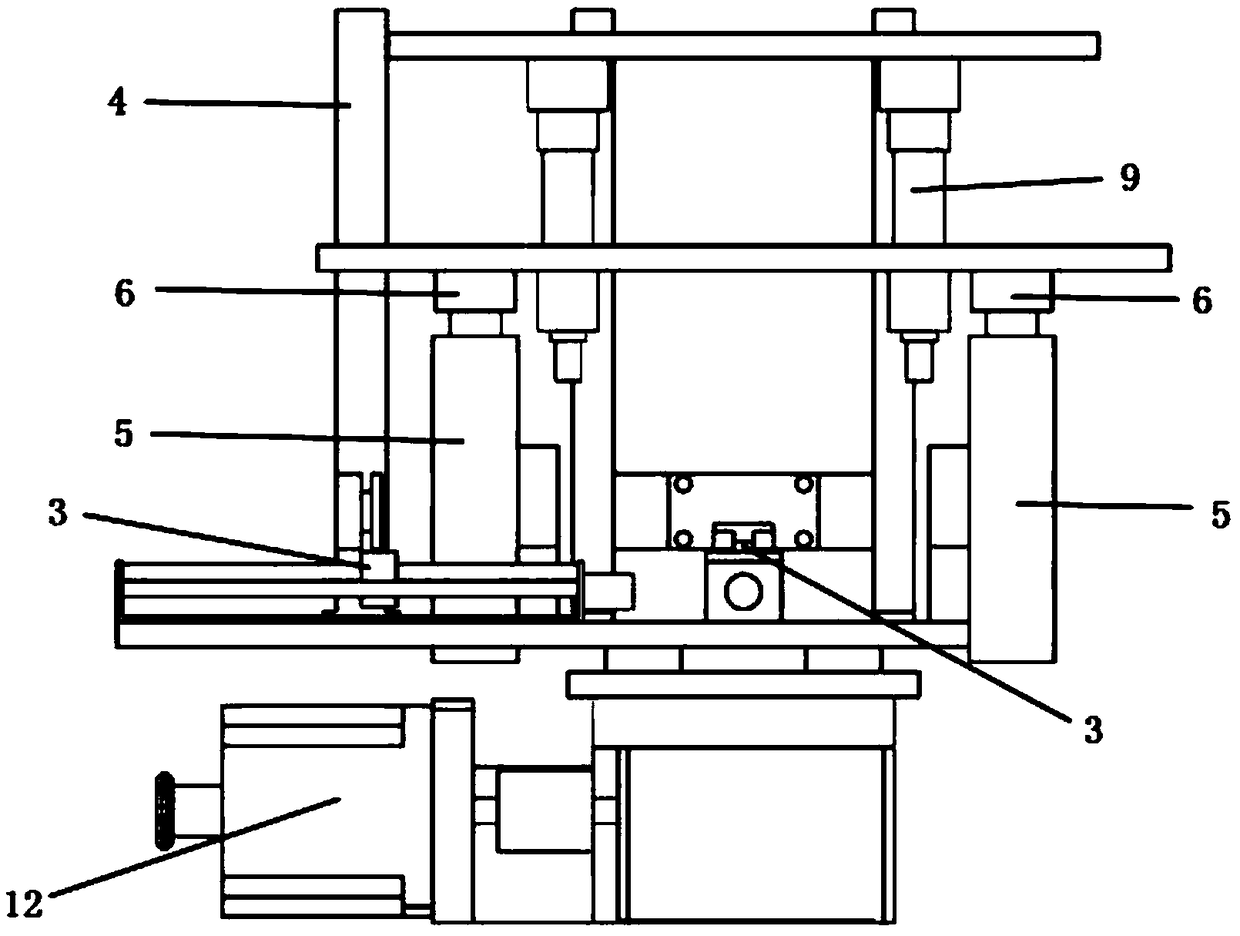

[0033] Such as Figure 1-2 As shown, the embodiment of the present invention provides a universal fixture for visual inspection of curved glass, the universal fixture includes a fixture support, an adjustable limit pin device, a cylinder device and a vacuum suction cup device. The fixture support includes a fixture base 1 and a suction cup base 2 . The adjustable limit pin device and the cylinder device are fixed on the fixture base 2 by bolts, the suction cup base 2 is installed on the cylinder device, and the vacuum suction cup device is installed on the suction cup base 2 .

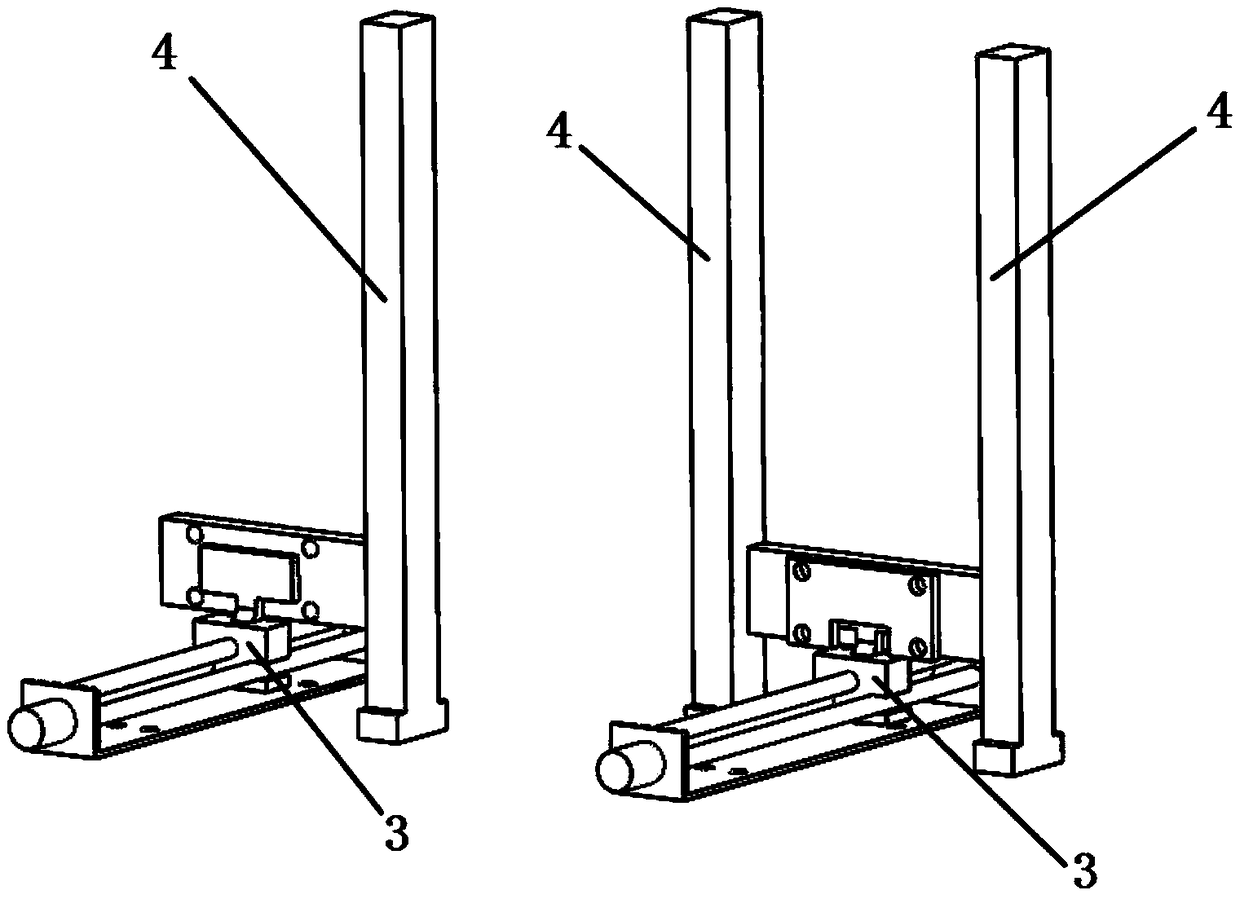

[0034] As shown in Figure 3, the general-purpose fixture includes two sets of adjustable limit pin devices, each set of adjustable limit pin devices includes a screw slider 3 and a limit pin 4, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap