Test equipment and test method for evaluating forming performance of product concrete

A technology for testing equipment and molding performance, which is applied in the direction of material inspection products, instruments, measuring devices, etc., and can solve problems such as backward evaluation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

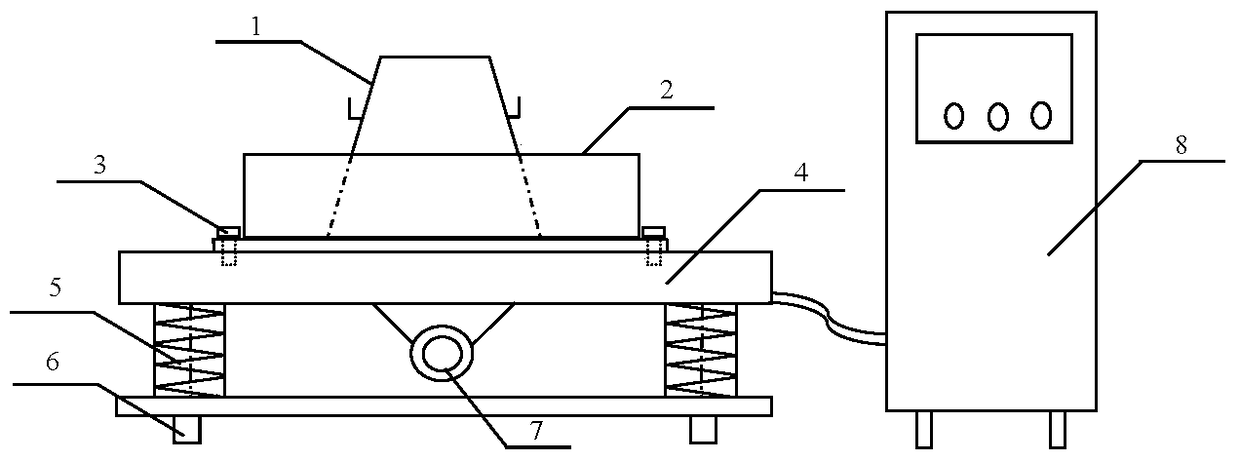

[0022] The embodiment of the present invention provides a test equipment and method for evaluating the formability of prefabricated sleeper concrete, which specifically includes the following contents:

[0023] 1. The frequency conversion vibration equipment such as figure 1 As shown, it consists of a vibrator (7), a vibration table (4), a frequency conversion control cabinet (8), a suspension and guide device for moving parts (5), a support device (6), a slump cylinder (1), and a special container The material container (2); the vibration frequency of the frequency conversion vibration equipment is 5Hz~200Hz, the accuracy is greater than or equal to 0.1Hz, the amplitude is less than or equal to 20mm, and the accuracy is greater than or equal to 0.01mm;

[0024] 2. Use the concrete slump tester to test the slump value of the newly mixed concrete to be 35mm, choose a type I container (2a) with a diameter (D1) of 240mm and a height (H1) of 150mm, and a special container ( 2) Sp...

Embodiment 2

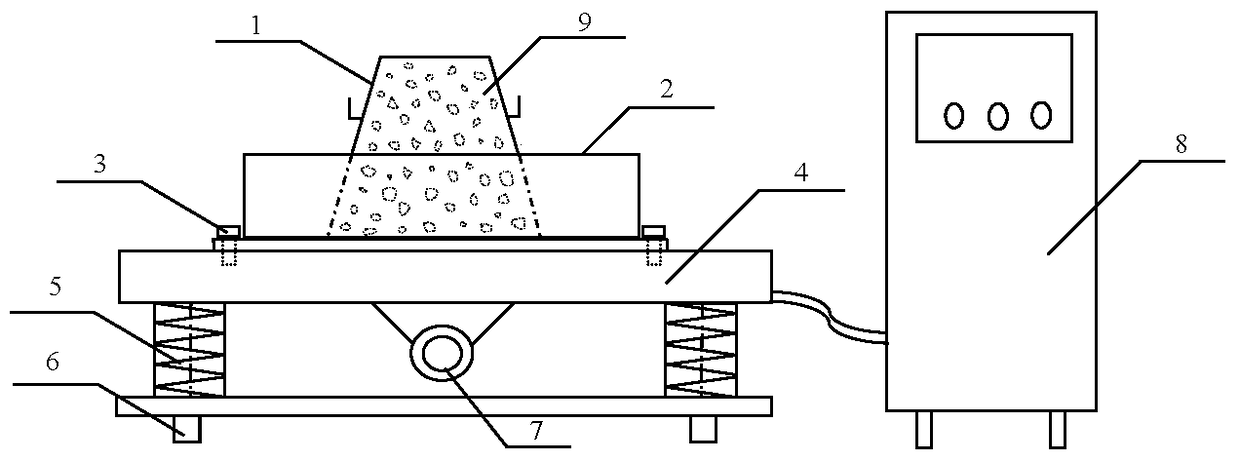

[0030] The embodiment of the present invention provides a test equipment and method for evaluating the formability of prefabricated track slab concrete, which specifically includes the following contents:

[0031] 1. Use a concrete slump tester to test the slump value of the newly mixed concrete, and the value is 110mm. Select a type II container (2b) with a diameter (D2) of 320mm and a height (H2) of 75mm. Wet slump cylinder (1) and Type II material storage container (2b), and ensure that there is no clear water on the inner wall of the slump cylinder (1) and the inner wall of the Type II material storage container (2b);

[0032] 2. Place the slump cylinder in the middle of the Type II container (2b), then put the mixed concrete (9) into the slump cylinder evenly in three layers, each layer of concrete (9), Use a tamping rod to form a spiral form from the edge to the center to insert and tamp 25 times evenly. After tamping, the height of each layer of concrete (9) is about on...

Embodiment 3

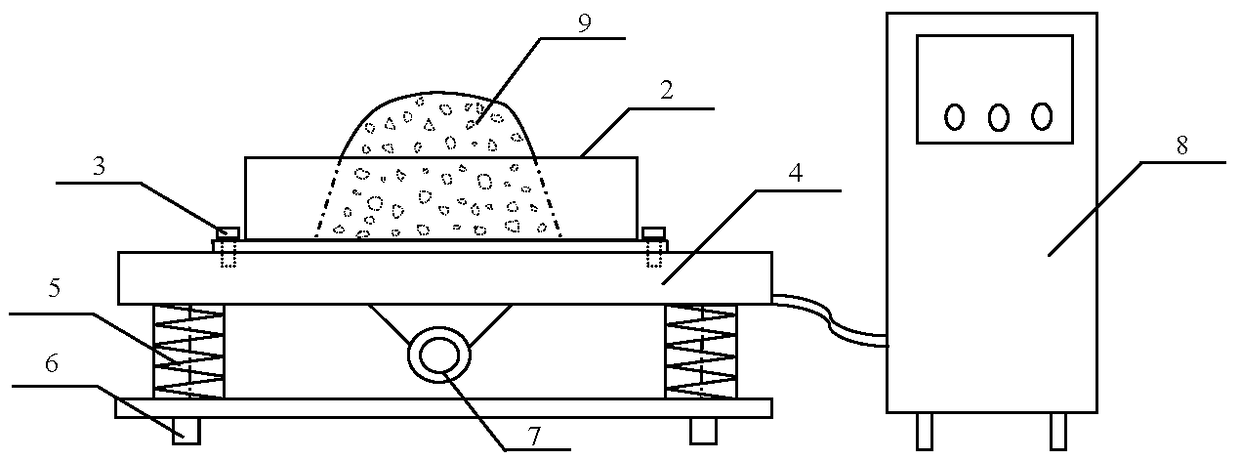

[0037] The embodiment of the present invention provides a test equipment and method for evaluating the formability of prefabricated box girder concrete, which specifically includes the following contents:

[0038] 1. Use a concrete slump tester to test the slump value of the newly mixed concrete to be 200mm, select a type IV container (2d) with a diameter (D4) of 600mm and a height (H4) of 25mm, wet slump cylinder (1) and Type IV material container (2d), and ensure that there is no clear water on the inner wall of the slump cylinder (1) and the inner wall of Type IV material container (2d);

[0039] 2. Place the slump cylinder (1) in the middle of the Type IV container (2d), then put the mixed concrete (9) into the slump cylinder (1) evenly in three layers, each For the concrete layer, use a tamping rod to insert and tamp 25 times evenly in a spiral form from the edge to the center. After tamping, the height of each layer of concrete (9) is about one-third of the height of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com