Infrared broadband antireflection microstructure and preparation method thereof

A microstructure and anti-reflection technology, applied in the coating and other directions, can solve the problems of difficult preparation and processing, high refractive index, achieve high transmittance, and meet the needs of large aspect ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

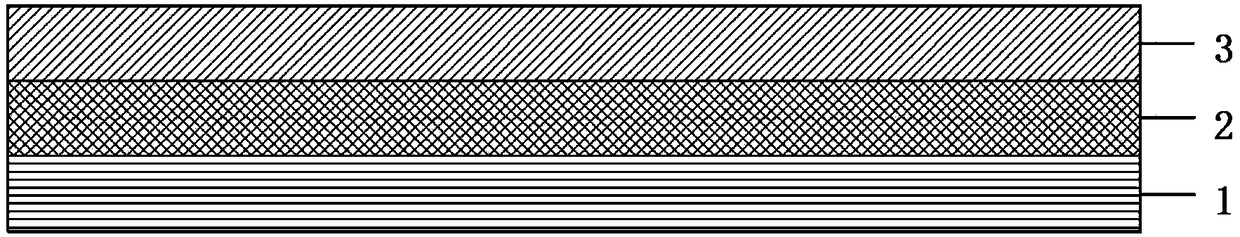

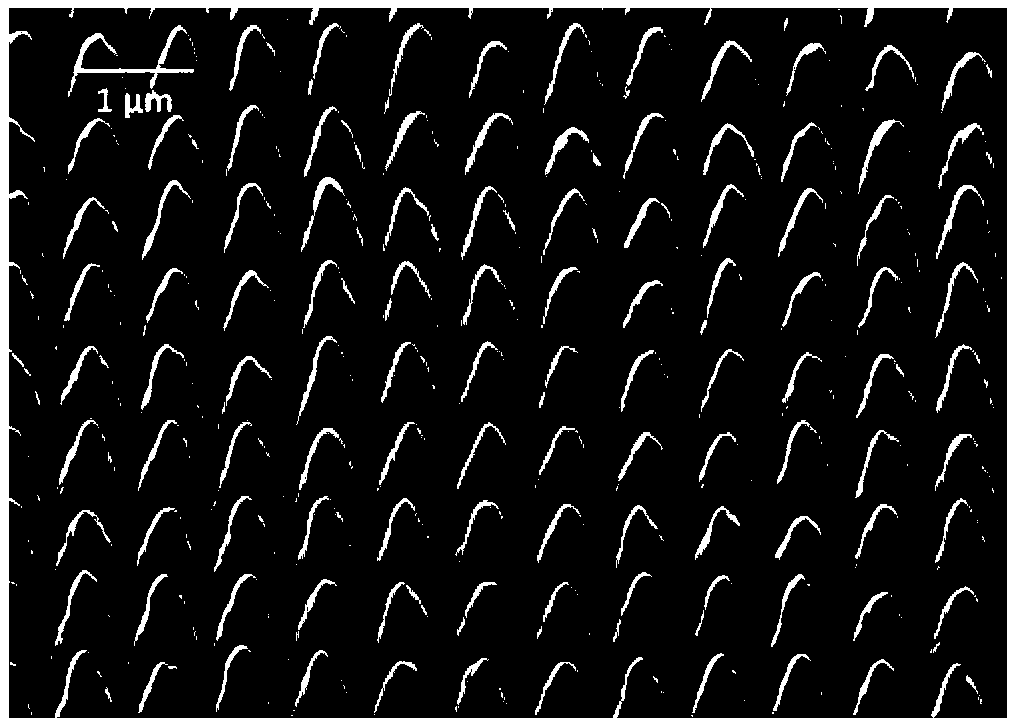

[0024] see figure 1 , figure 1 It is a schematic diagram of the infrared broadband anti-reflection microstructure of the present invention, as shown in the figure, including a substrate 1, a nanostructure array layer 2 and a single-layer low-refractive index layer 3 from bottom to top. In this example, the infrared window material is used as the preferred material, and microstructures are prepared on its surface, so as to increase its infrared broadband transmittance.

[0025] In this example, zinc selenide is selected as the base material. Zinc selenide is an optical material with good transmittance in the infrared band, and the sample needs to be polished on both sides.

[0026] Specifically, the preparation method of the broadband anti-reflection microstructure of this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com