Reactive power compensation device

A technology of power compensation and magnetic latching relay, which is applied in reactive power compensation, reactive power adjustment/elimination/compensation, circuit devices, etc., and can solve the problem that magnetic latching relays have offsets in closing time and off time and affect magnetic latching relays. And capacitor service life, high-frequency inrush current and other issues, to achieve the effect of suppressing high-frequency inrush current and overvoltage, improving service life and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

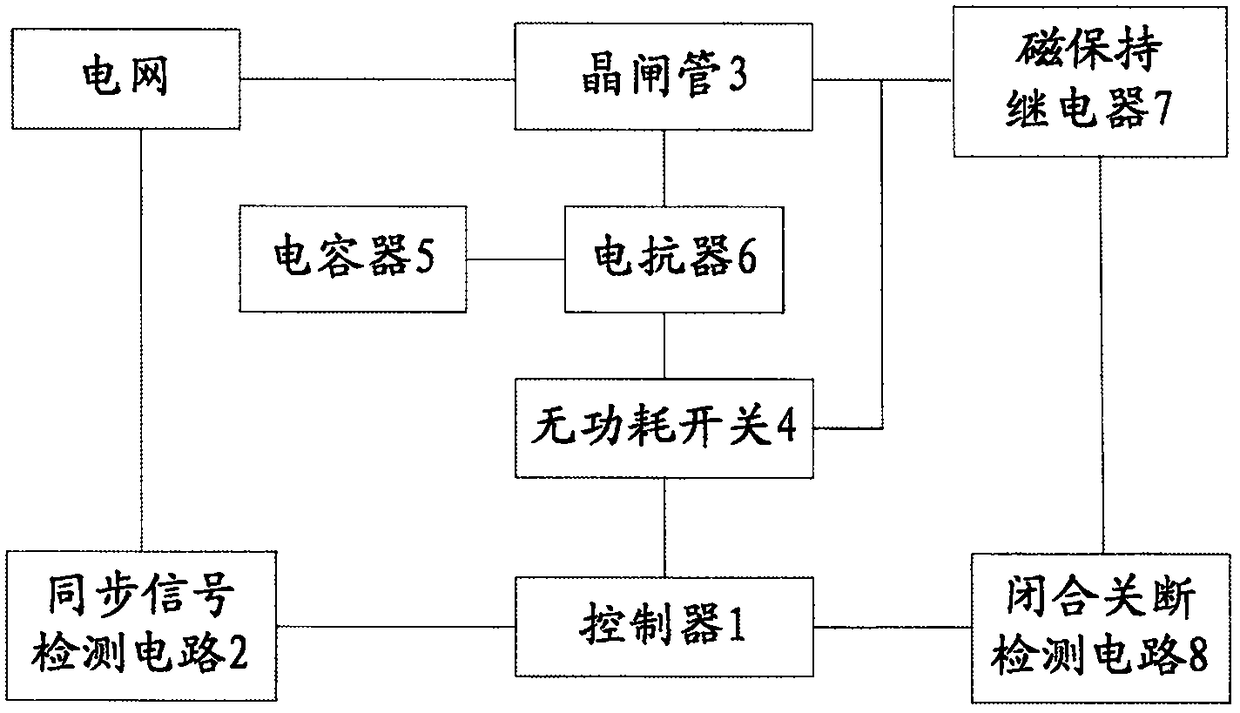

[0024] figure 1 It is a structural connection diagram of the reactive power compensation device of the present invention. Such as figure 1 As shown, the reactive power compensation device includes: a controller 1, a synchronous signal detection circuit 2, a thyristor 3, a non-power consumption switch 4, a capacitor 5, a reactor 6, a magnetic latching relay 7 and a closed-off detection circuit 8 ; The controller 1 is respectively connected with the synchronous signal detection circuit 2, the thyristor 3, the non-power consumption switch 4, the magnetic latching relay 7 and the closing and closing detection circuit 8, the thyristor 3 and the non-power consumption switch 4 are connected in parallel, and the thyristor 3 passes through the reactor 6 is connected with the capacitor 5; the magnetic latching relay 7 is connected with the thyristor 3.

[0025] The present invention can switch the capacitor group through the thyristor module when the voltage crosses zero, reducing the...

Embodiment 2

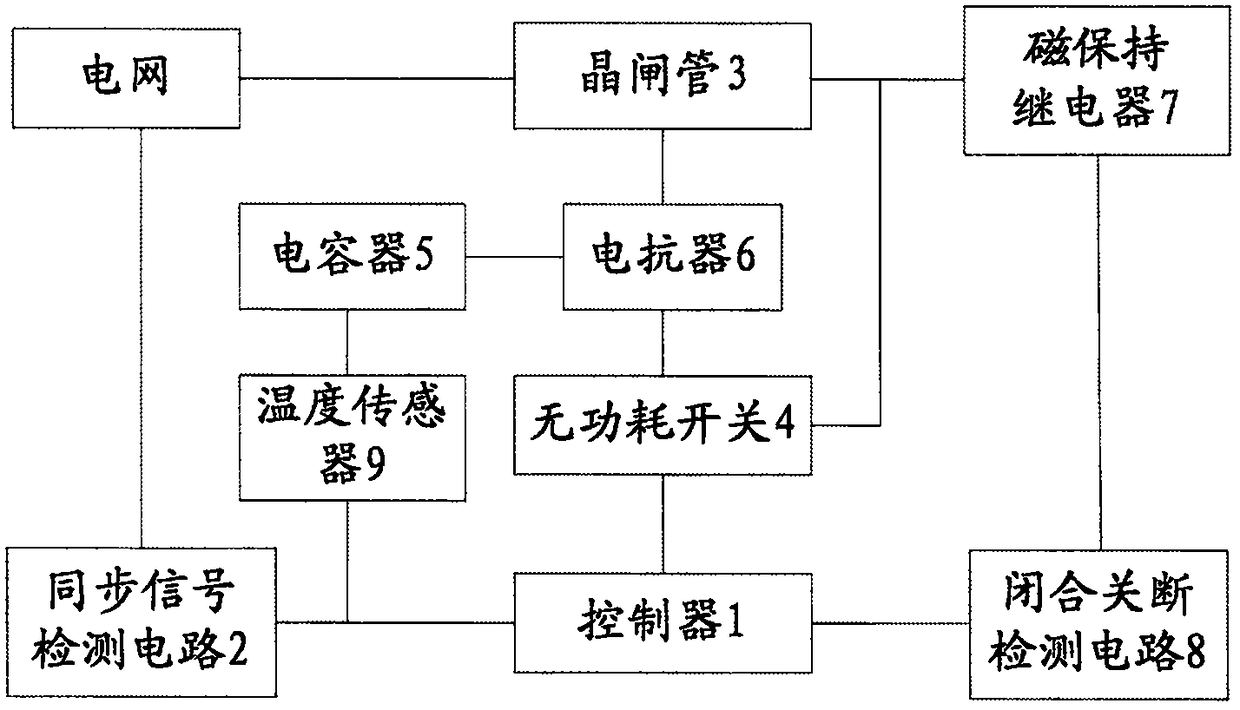

[0032] On the basis of Embodiment 1, the reactive power compensation device further includes a temperature sensor 9 , one end of the temperature sensor 9 is connected to the capacitor 5 , and the other end is connected to the controller 1 . The temperature sensor of the invention can monitor the online operation temperature of the capacitor in real time, so as to ensure the safe and reliable operation of the power grid.

Embodiment 3

[0034] On the basis of Embodiment 1, the synchronous signal detection circuit 2 of Embodiment 3 includes a signal conditioning circuit and a three-phase electric energy parameter acquisition module connected in sequence, the signal conditioning circuit is connected to the power grid, and the three-phase electric energy parameter acquisition module is connected to the controller 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com