Smart Capacitors for On-Site Zero-Crossing Switching Correction

A technology of zero-crossing switching and capacitors, which is applied in reactive power compensation, reactive power adjustment/elimination/compensation, etc., can solve the problem of parameter changes. Meet the problems of suppressing inrush current and overvoltage, unable to correct the zero-crossing switching time, etc., to achieve the effects of suppressing high-frequency inrush current and overvoltage, improving service life and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention provides an intelligent capacitor for on-site zero-crossing switching correction. The present invention will be further described below through the description of the drawings and specific implementation methods.

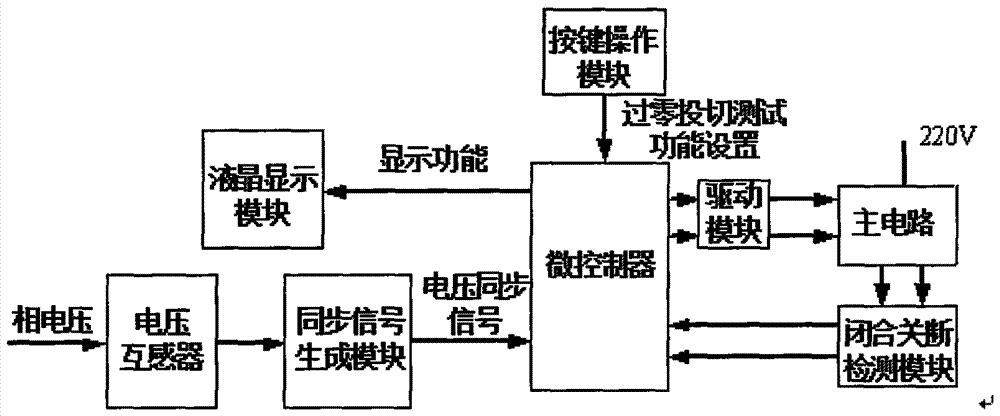

[0015] Take phase a zero-crossing switching correction as an example to illustrate, figure 1 It is a schematic structural diagram of the phase a of the intelligent capacitor for on-site zero-crossing switching correction of the present invention. module and main circuit. The zero-crossing and switching correction function is added in the single-chip microcomputer program. The function is displayed by the liquid crystal display module, and the function is input by the key operation module. When the zero-crossing correction function is selected, the single-chip microcomputer zero-crossing and switching correction program is entered.

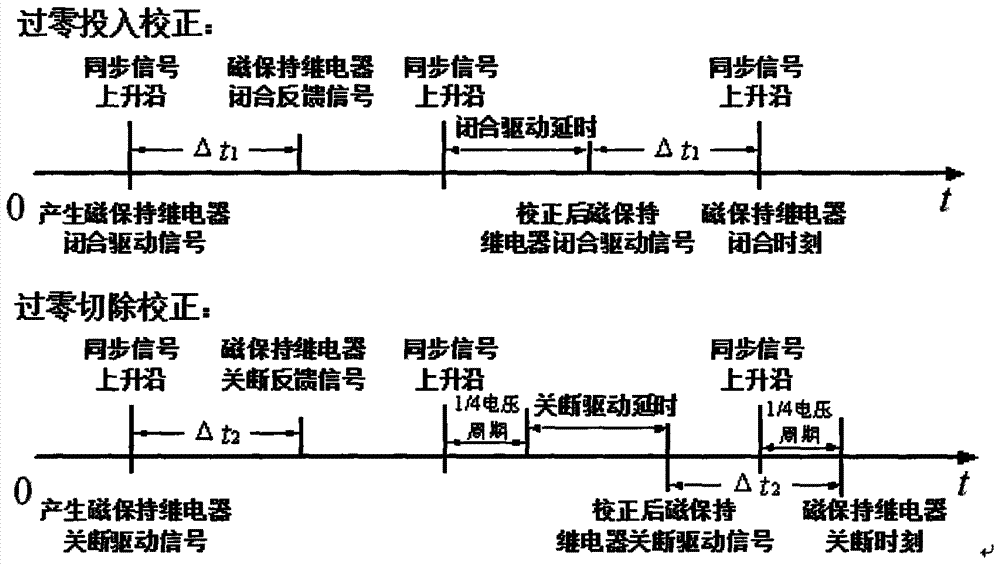

[0016] figure 1 The detected a-phase voltage signal is compared with zero crossing to generate a synchro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com