Automatic drilling device for surface air cooler main pipe

A technology for drilling devices and surface coolers, which is applied to positioning devices, boring/drilling, drilling/drilling equipment, etc., can solve the problems of time-consuming and labor-intensive, low benefit, etc., to improve work efficiency, The effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

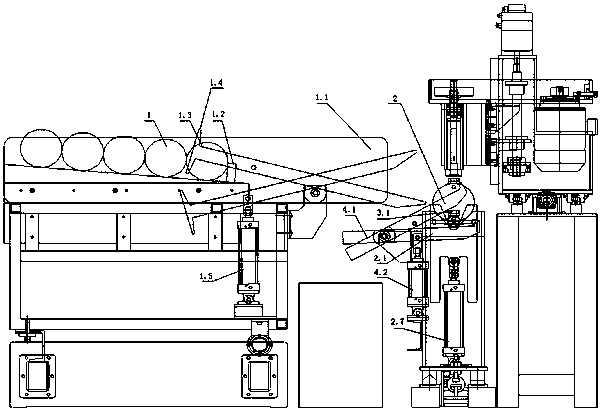

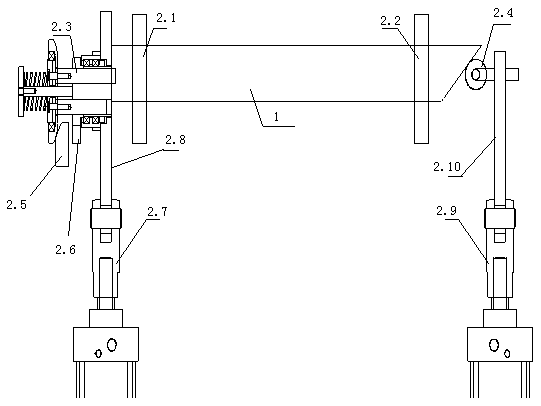

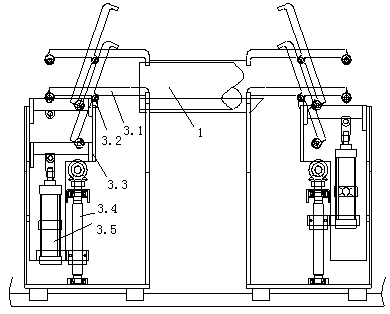

[0024] see Figure 1-3 , The present invention relates to an automatic drilling device for the main pipe of a surface cooler, which includes an automatic feeding device, an automatic positioning device, an automatic clamping device, an automatic drilling device and an automatic unloading device.

[0025] The automatic feeding device includes a triangular discharge rack 1.1, a material retaining block 1.2, a feeding scraper 1.3, a material distribution port 1.4 and a feeding cylinder 1.5, the triangular discharge rack 1.1 is arranged obliquely, and a stopper is provided at the lower end of the inclination. The material block 1.2 and several workpieces 1 are arranged on the triangular discharge rack 1.1, and the material is stopped by the material block 1.2, and the workpieces 1 are in a state of static equilibrium. The two sides of the first workpiece close to the blocking block 1.2 are respectively provided with the same feeding scraper 1.3, one end of the feeding scraper 1.3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com