A hydraulic semi-automatic screen changing device for an extruder

An extruder and semi-automatic technology, applied in the field of extruder filter automatic replacement device, can solve the problems of melt leakage, long working time, harsh working environment, etc., to ensure the locking torque, effective use of space, and device structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the drawings and specific embodiments.

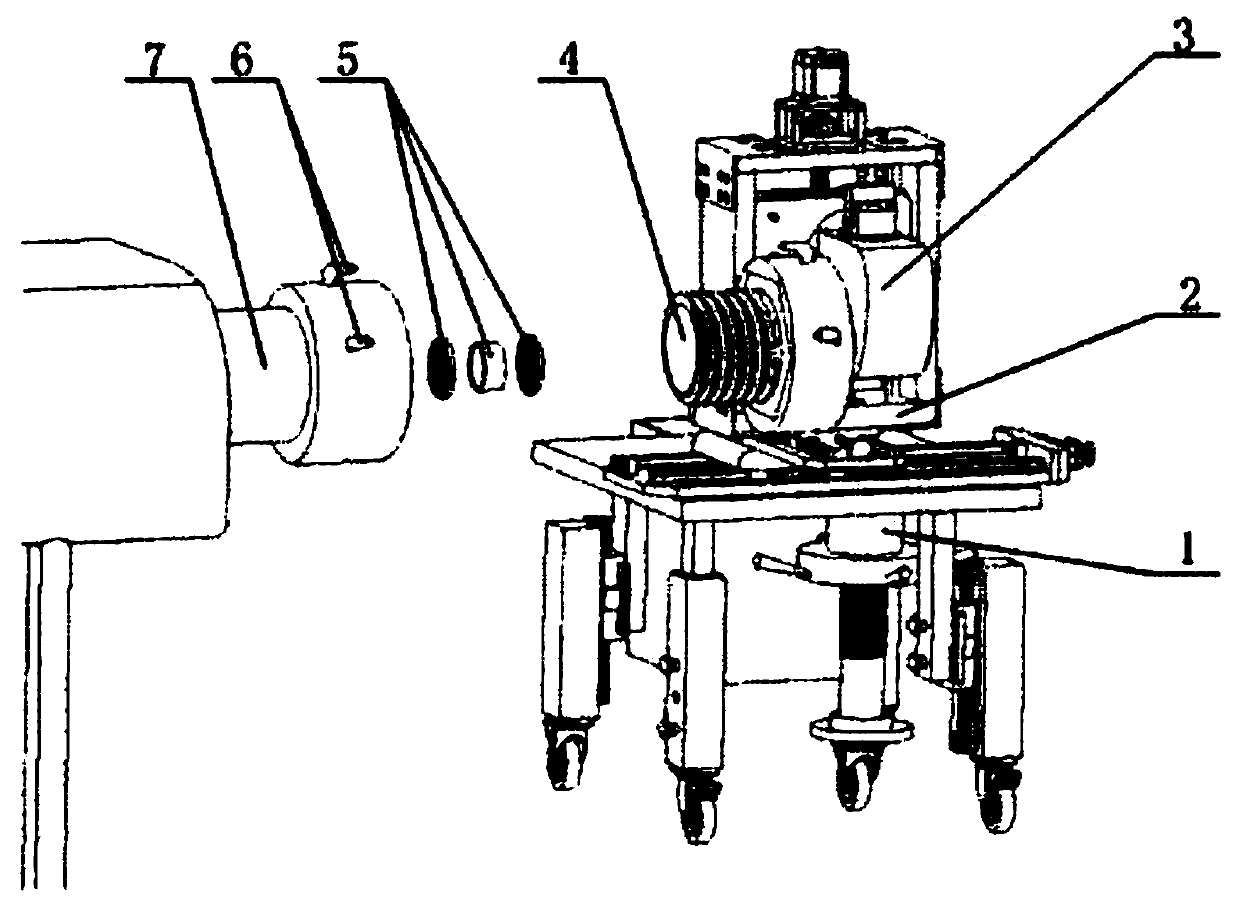

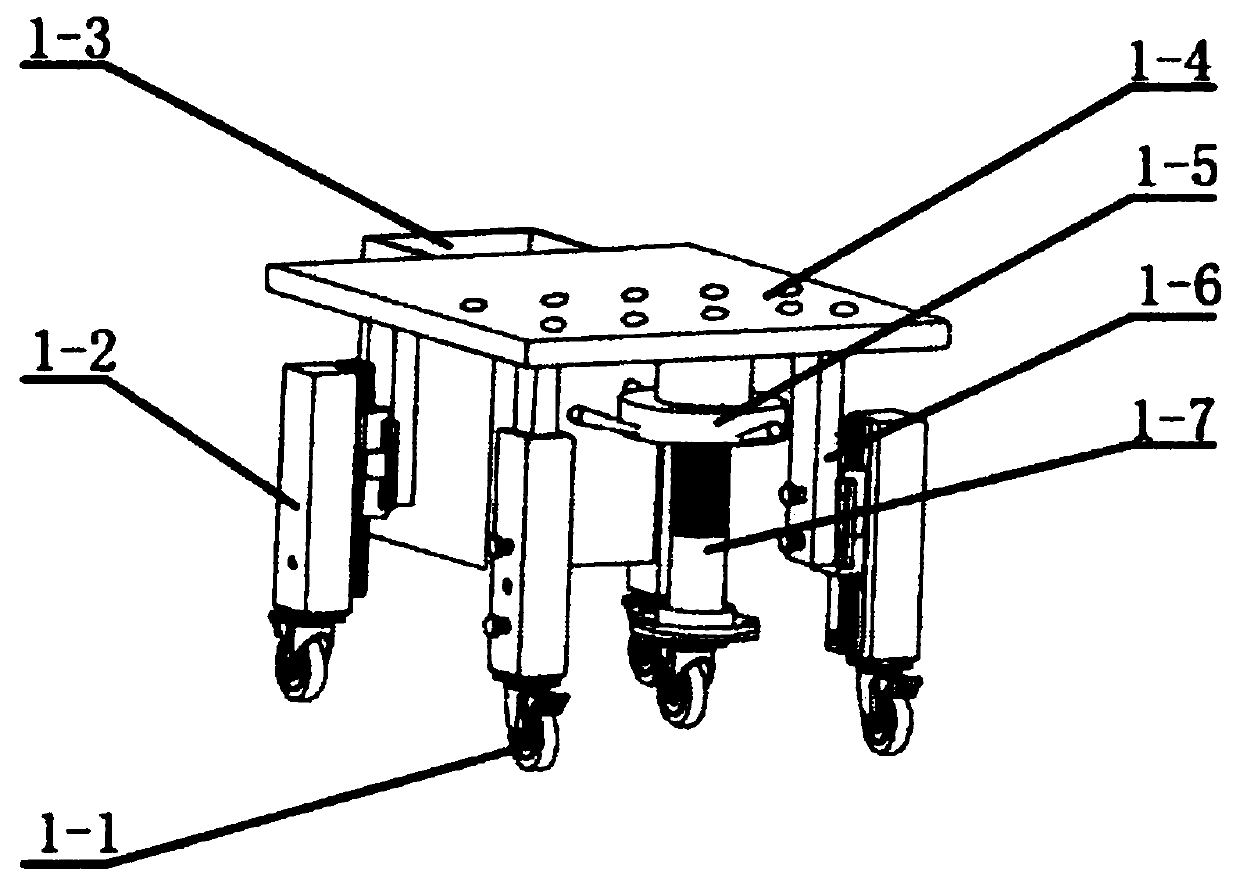

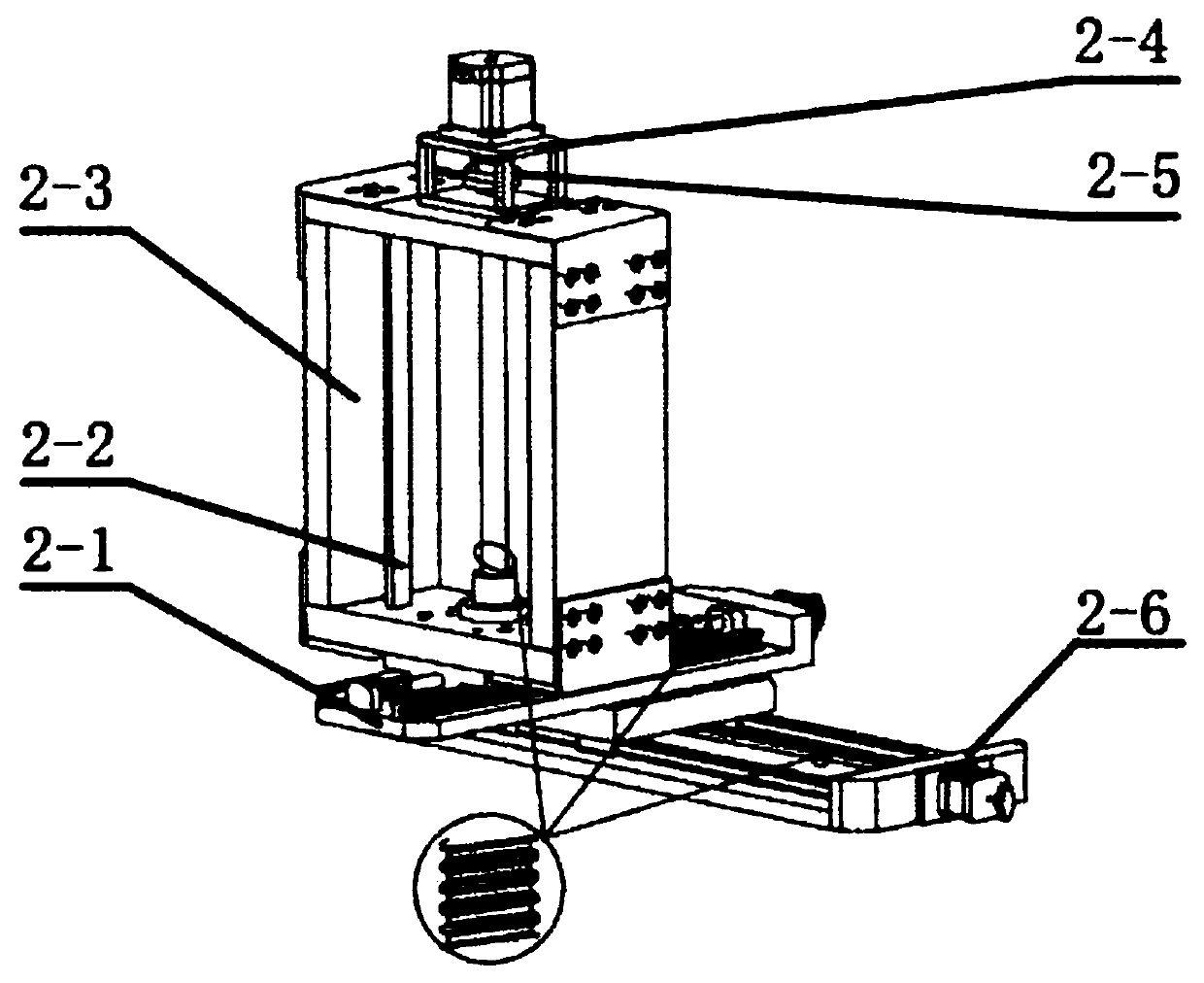

[0023] As shown in Figure (1), a hydraulic (semi) automatic screen changing device for an extruder includes: a walking lifting platform component (1), a space positioning platform component (2), and a hydraulic rotating arm component (3). The walking lifting platform parts (1) are composed of fixed casters (1-1), table leg frames (1-2), hydraulic cylinders (1-3), bases (1-4), lifting knobs (1-5), The lifting guide rail (1-6) and the thread lifting column (1-7) are composed; the space positioning table part (2) is composed of the cross table guide rail a (2-1), the linear guide rail (2-2), the translation frame ( 2-3), motor frame (2-4), coupling (2-5), cross table guide rail b (2-6); hydraulic rotating arm part (3) consists of wrench socket (3-1), The connection plate (3-2), guide rail slider (3-3), lead screw (3-4), photoelectric positioning sensor (3-5),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com