Manufacturing method of yawing composite ceramic bulletproof plate

A technology of composite ceramics and bulletproof plates, applied in the structure of armor plates, chemical instruments and methods, protective clothing, etc., can solve problems that cannot meet the requirements of kinetic energy projectile blocking, single structure bulletproof plates to reduce surface density and bulletproof requirements, and achieve The effect of improving the anti-ballistic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Prepare GUR 4113UHMW-PE ultra-high molecular weight polyethylene powder (UHMWPE) 0.2kg.

[0038] Prepare a piece of aluminum foam board with a size of 300×250×20 (unit: mm), unit volume density 0.4g / cm 3 .

[0039] Prepare 99.5% alumina ceramic balls with a diameter of 12 mm and a quantity of 340.

[0040] Prepare a hot-pressed silicon nitride ceramic plate with a size of 112×112×11 (unit: mm).

[0041] Prepare an iron-based amorphous thin strip with a width of 170 mm, a thickness of 0.03 mm, and a weight of 2 kg.

[0042] Prepare SY-24C resin glue.

[0043] Prepare a set of composite molds for bulletproof plates.

[0044] Process steps:

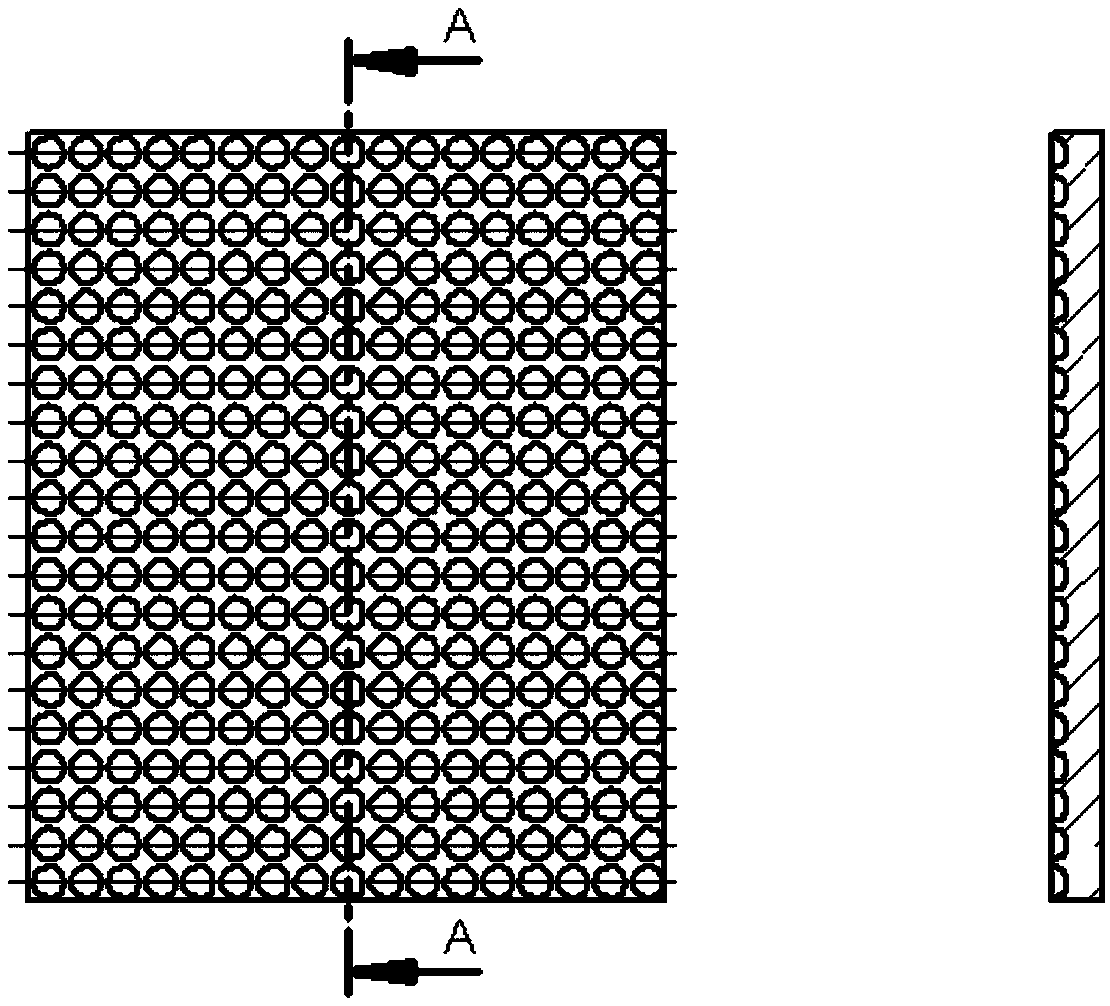

[0045] (1) Firstly, the aluminum foam board is processed into such as figure 1 structure shown.

[0046] (2) Put the structure obtained in step (1) into the mold on the plastic press workbench, with the concave side of the ball facing upwards, and fill 340 alumina ceramic balls with a diameter of 12mm in the conca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com