High-efficiency soilless culture device for greenhouse agriculture

A technology of soilless cultivation and greenhouse, which is applied in the field of soilless cultivation devices for high-efficiency greenhouse agriculture, which can solve problems such as uneven addition of nutrient solution, lack of plant support measures, damage to plant roots, etc., to achieve enhanced practicability, convenient cleaning, Add an even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

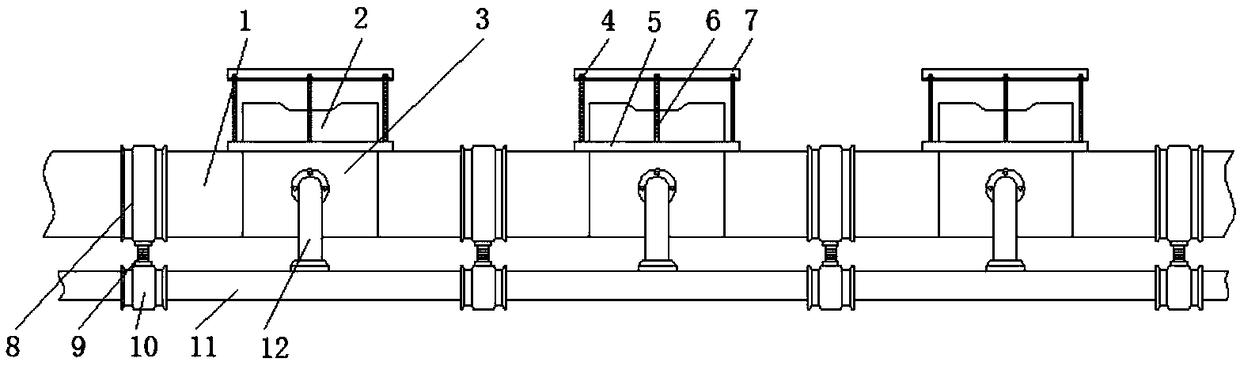

[0025] Embodiment one, with reference to Figure 1-4 , a high-efficiency soilless cultivation device for greenhouse agriculture, comprising a soilless cultivation main pipe 1, a plurality of cultivation chambers 3 are equidistantly embedded on the soilless cultivation main pipe 1, and the cultivation chambers 3 and the inside of the soilless cultivation main pipe 1 Mutual conduction, the top of the cultivation bin 3 is connected to the cultivation bracket 2, and the main pipe 1 of the soilless cultivation is equidistantly socketed with a plurality of first fixed sleeves 8, and the bottoms of the plurality of first fixed sleeves 8 are connected by connecting screw rods. 9 is connected with a second fixed pipe sleeve 10, wherein a plurality of second fixed pipe sleeves 10 are embedded and fixed with nutrient solution supplementary pipes 11, and the nutrient solution supplementary pipes 11 are equidistantly connected with connecting branch pipes 12 through fixed nuts. The soil cu...

Embodiment 2

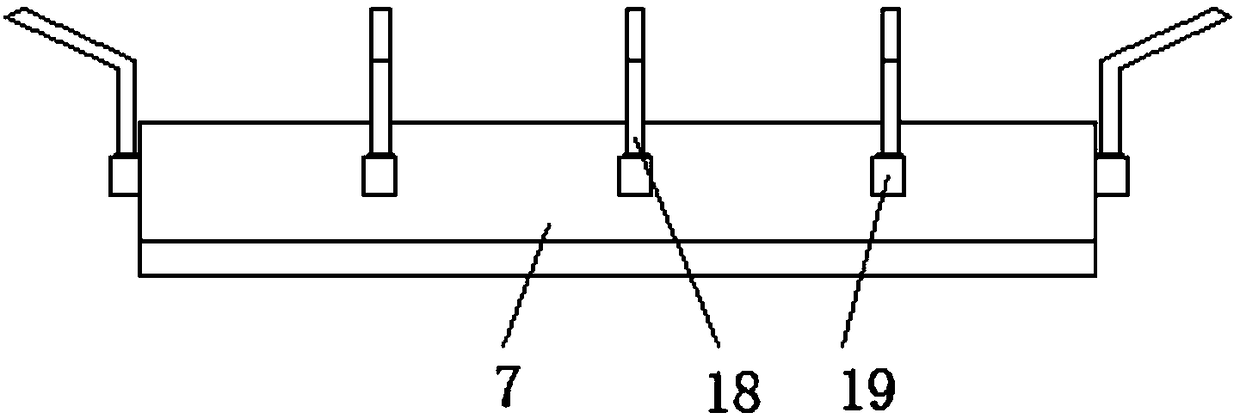

[0026] Embodiment two, refer to figure 1 and image 3 The outer casing of the cultivation bracket 2 is spirally sleeved with an annular sleeve frame 5, and the top of the annular sleeve frame 5 is spirally connected with six adjusting screws 6 at an equal angle in a ring, and the top ends of the six adjusting screw rods 6 are adjusted Nut 4 is spirally fixed with annular support frame 7, and annular support frame 7 and cultivation bracket 2 are ring-shaped structures, and the diameters of annular support frame 7 and cultivation bracket 2 are equal, and the outer casing of annular support frame 7 is Annular equal angles are fixed with auxiliary bracket 18 by fixing seat 19 screw, can adjust the adjustment screw rod 6 by adjusting nut 4 according to the different plant varieties cultivated, and then adjust the height of the ring support frame 7, so that the ring support frame 7 The auxiliary bracket 18 connected thereto can support the cultivation of plants of different heights...

Embodiment 3

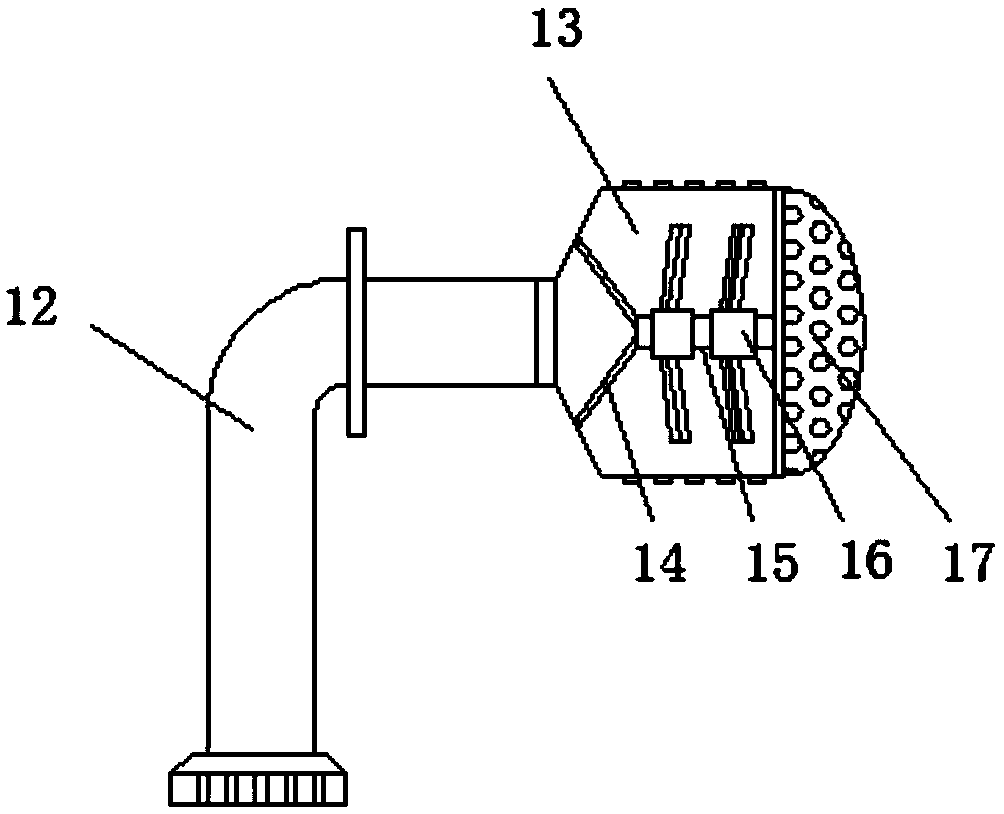

[0027] Embodiment three, refer to Figure 1-2 , the top of the connecting branch pipe 12 runs through the soilless cultivation main pipe 1 and the cultivation bin 3 and communicates with the nutrient solution addition head 13 inside the cultivation bin 3, and the outer shell of the nutrient solution addition head 13 is uniformly provided with a liquid outlet 17, The inside of the nutrient solution adding head 13 is connected with the rotating shaft 15 through the rotation of the Y-shaped fixed frame 14, and the rotating shaft 15 is equidistantly rotated and connected with the screw blade 16, and the connection position of the connecting branch pipe 12 and the soilless cultivation main pipe 1 is set It is connected with a fixed sleeve frame for limiting the connecting branch pipe 12. Through the connecting branch pipe 12 and the nutrient solution adding head 13, the nutrient solution is directly added to the inside of the cultivation chamber 3, so that the nutrient solution is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com