Safe changing system of gamma knife radiation treatment equipment radioactive source

A technology of radiotherapy and Gamma Knife, which is applied in the field of safe replacement system of radioactive sources of Gamma Knife radiotherapy equipment, can solve the problems of time-consuming and manpower, and achieve the goals of reducing the workload of on-site personnel, improving quality control, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

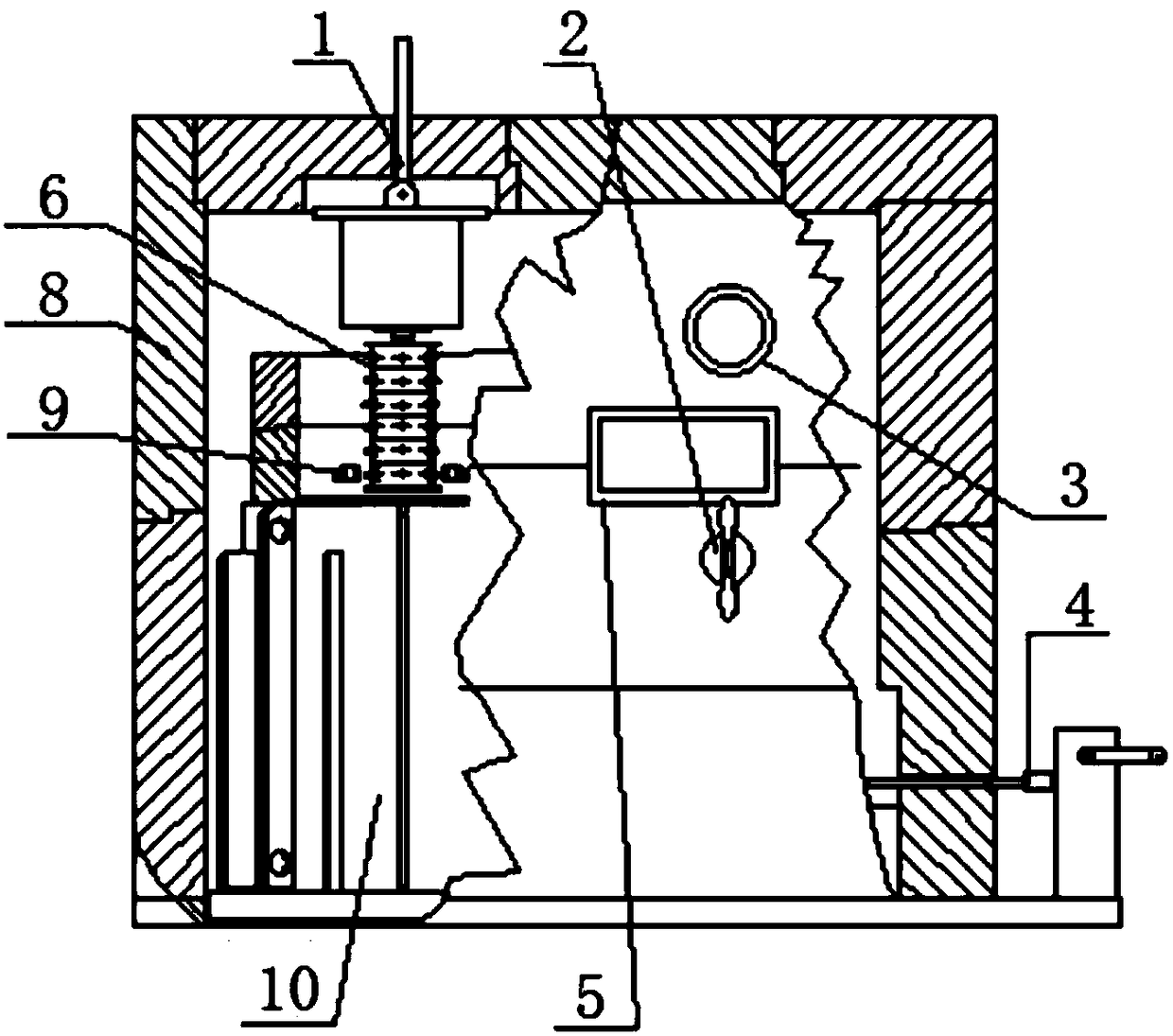

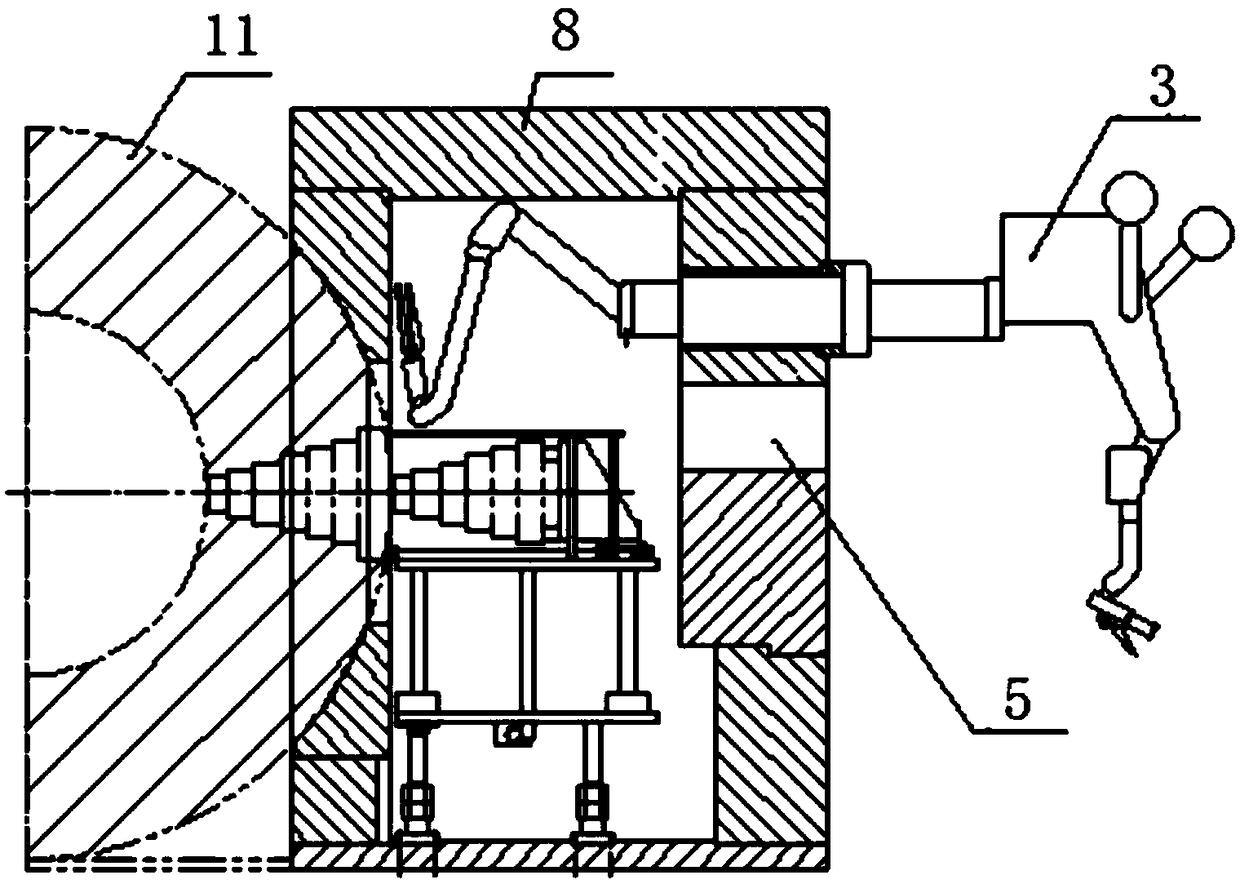

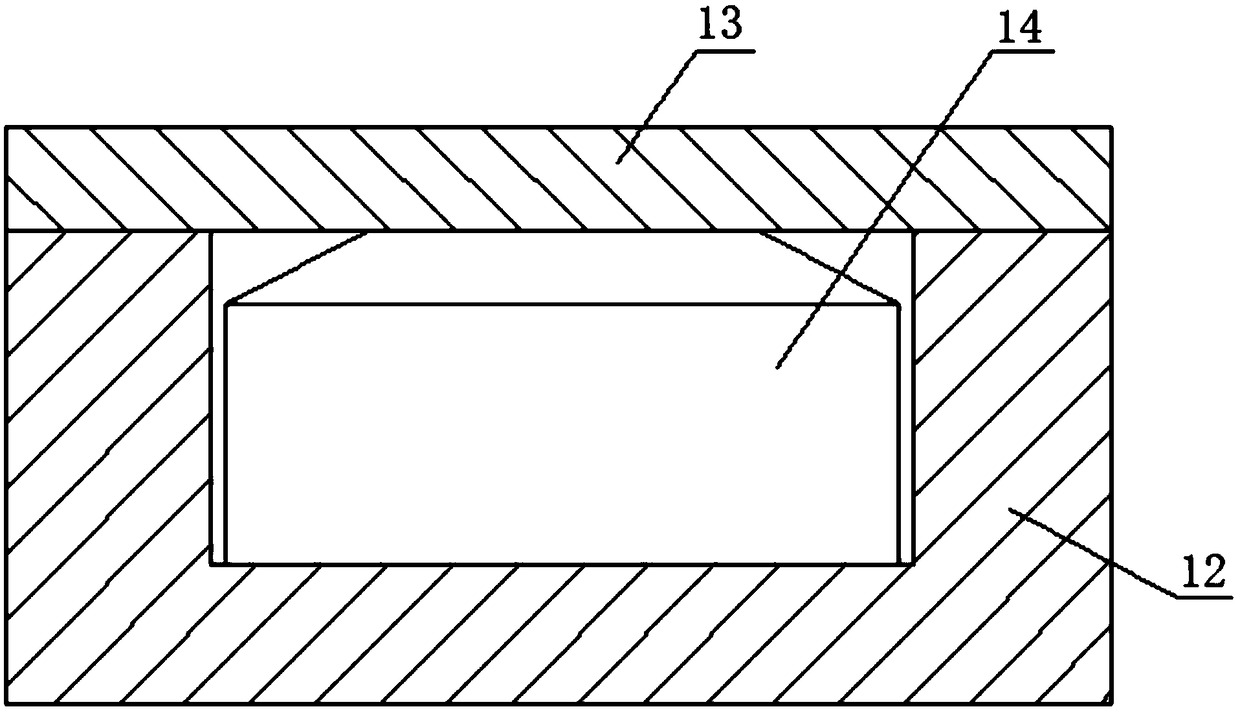

[0055] Embodiment 1: as attached figure 1 As shown, above the bracket 27, place the lead stopper frock 29, place the frock cover 31 or replace the source frock 26 in the middle part above the lead stopper frock 29; wherein, the lead plug frock 29 middle part is developed toward the edge of one side, and the upper and lower end faces are straight-through The installation slot and the tooling drawer 30 are slidingly placed therein. There is a vertical channel in the Z-axis direction in the middle part of the source tooling 26. The upper section of the vertical channel is a shaft hole. The X-axis chute communicates orthogonally and vertically, and the lower section of the vertical channel communicates with the slide rail in the X-axis or Y-axis, wherein one end of the X-axis chute is open and the other end is closed, and a shielding body 32 is placed in the X-axis chute , and the lower lead plug 24 is placed in the slide rail, and the inner section of the X-axis chute is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com