Water purification system and control method thereof

A technology of water purification system and control method, which is applied in the direction of water treatment parameter control, chemical instruments and methods, water/sewage treatment, etc., and can solve the problems of small water discharge in pressure tanks, waste, and inability to realize reverse osmosis filter flushing, etc. Achieve the effects of prolonging the service life, saving water, and avoiding concentration polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

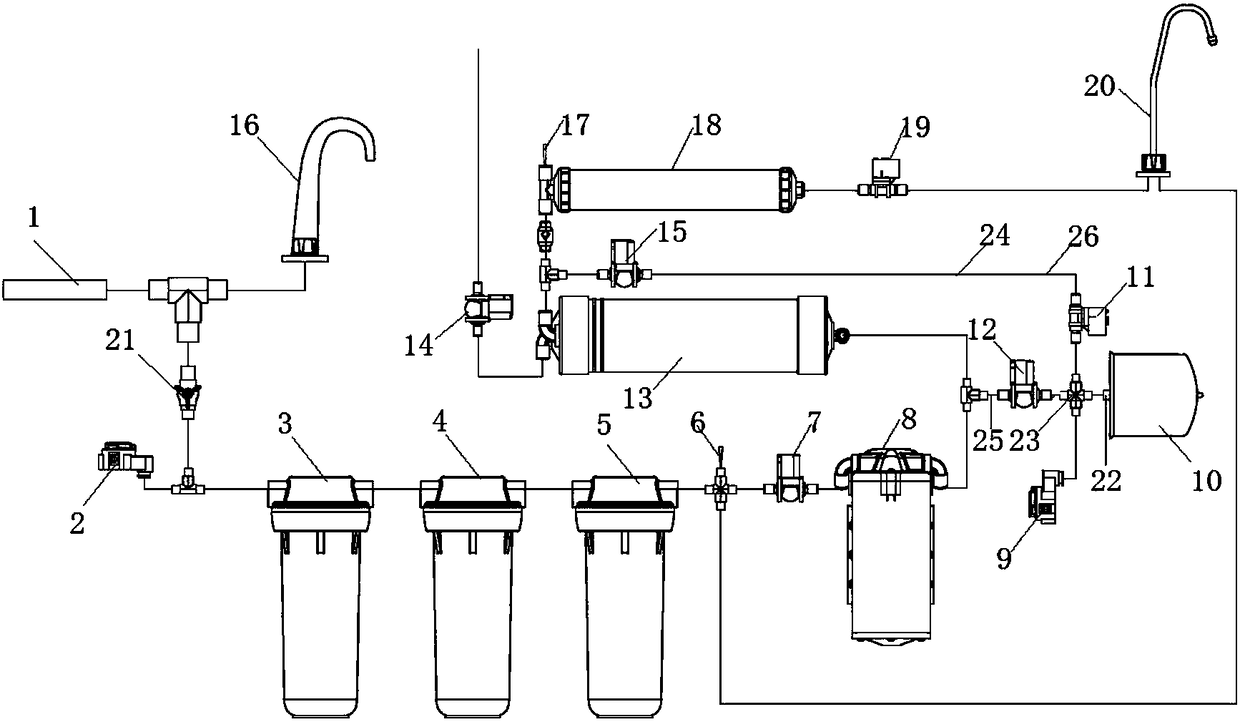

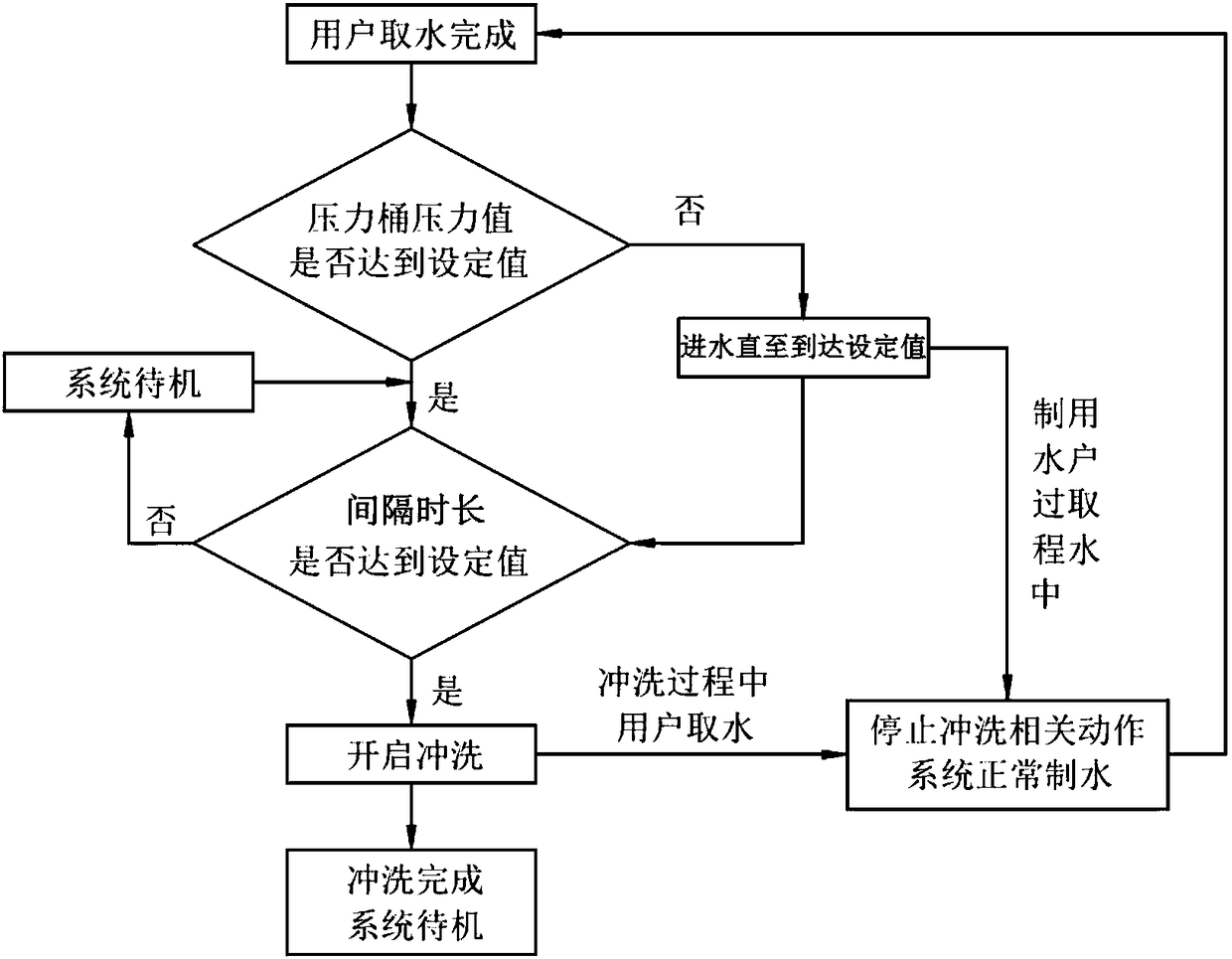

[0034] Such as figure 1 , 2 As shown, in this embodiment, the water purification system includes a branch 26 arranged in parallel with the reverse osmosis filter 13, the branch 26 is provided with a pressure tank 10, and the pressure tank 10 is filtered with the reverse osmosis through the outlet pipeline 25 The device 13 is connected, and the outlet pipeline 25 is provided with a second low pressure switch 9 for detecting the pressure in the pressure barrel 10, so that the control module of the water purification system can judge whether to stop the reverse osmosis filter according to the detection value of the second low pressure switch 9 The flushing work of device 13.

[0035] When the pressure in the pressure barrel 10 was too low, the amount of water discharged from the pressure barrel 10 was extremely small, and the flushing of the reverse osmosis filter 13 could not be realized. The pressure in the pressure tank 10, before the pressure in the pressure tank 10 is too ...

Embodiment 2

[0044] Such as figure 1 , 2 As shown, in this embodiment, the pressure barrel 10 is connected to the pure water outlet of the reverse osmosis filter 13 through the water inlet pipeline 24, and the water inlet pipeline 24 is provided with a second high pressure for detecting the pressure inside the pressure barrel 10 The switch 11 enables the control module of the water purification system to judge whether to stop water intake into the pressure tank 10 according to the detection value of the second high pressure switch 11 .

[0045] The water outlet and the water inlet of the pressure tank 10 are the same opening 22 , and the opening 22 communicates with the water inlet pipeline 24 or the water outlet pipeline 25 respectively through the adapter 23 .

[0046] The water inlet pipeline 24 is provided with a first valve 15 for controlling the on-off of the pipeline.

[0047] In this embodiment, the corresponding states of the water purification system are as follows:

[0048] S...

Embodiment 3

[0060] In the present invention, the water in the pressure barrel 10 can flush the reverse osmosis filter 13 from the pure water outlet of the reverse osmosis filter 13 .

[0061] In this embodiment, the corresponding states of the water purification system are as follows:

[0062] State 1. The user closes the pure water faucet, the water purification system ends the water production mode, the second high pressure switch 11 detects the pressure in the pressure tank 10, when the pressure in the pressure tank 10 reaches the first set value of the second high pressure switch 11 , the water purification system enters the flushing mode; when the pressure in the pressure tank 10 is lower than the first set value of the second high pressure switch 11, the water purification system enters the water production mode, the first valve 15 is opened, and the flushing solenoid valve 14 is half open state, pure water enters the pressure tank 10 until the pressure in the pressure tank 10 reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com