Method and system for online testing and grinding of long metal material

A long material and metal technology, applied in the field of online flaw detection and grinding, can solve the problems of low production efficiency, product designation confusion, and large personnel investment, so as to achieve the effect of improving production efficiency, avoiding product designation confusion and reasonable configuration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

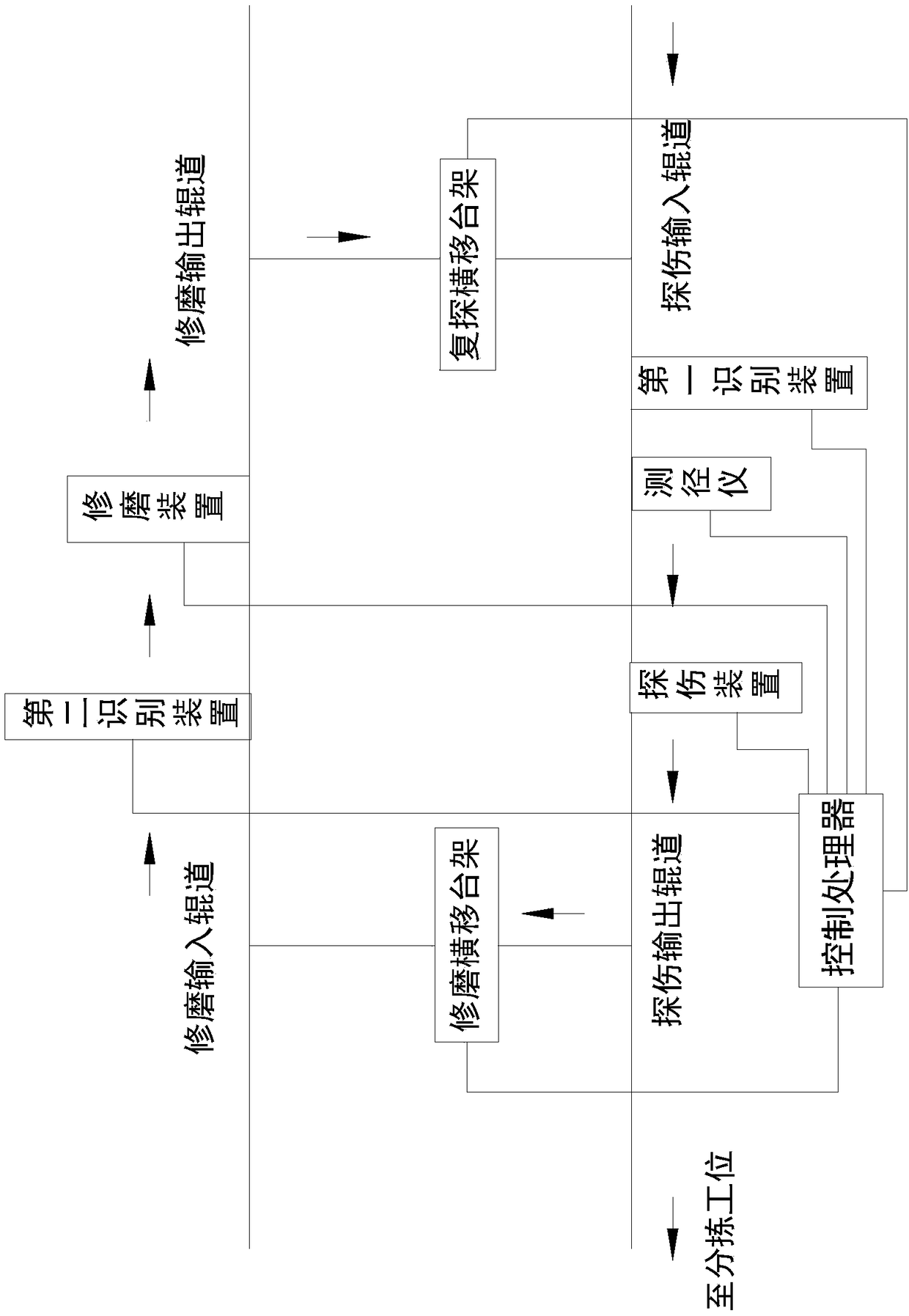

Image

Examples

Embodiment Construction

[0010] The present invention is further described below in conjunction with embodiment and accompanying drawing.

[0011] The method for on-line flaw detection and grinding of metal long products provided by the embodiments of the present invention has the following specific steps:

[0012] 1) Mark the incoming metal long products one by one. The specific method used for marking is to attach an RFID tag or a two-dimensional code tag to the end of the metal long material, and the attachment method is magnetic adsorption, so as to facilitate installation and removal.

[0013] 2) Identify and measure the diameter of metal long products one by one. According to the attached label, the corresponding identification device is an RFID reader-writer or a two-dimensional code identifier for identification, and the existing caliper is used for measuring the diameter.

[0014] 3) Flaw detection of metal long products one by one. The flaw detection method can be infrared, magnetic flux ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com