Noise reduction type drilling equipment for steel machining

A kind of drilling equipment and noise reduction technology, which is applied in the field of drilling equipment for noise reduction steel processing, can solve the problems of insufficient matching of components, increase the cost of equipment use, short service life of drill bits, etc., so as to reduce collision and prolong use. The effect of life and maintenance of the use environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

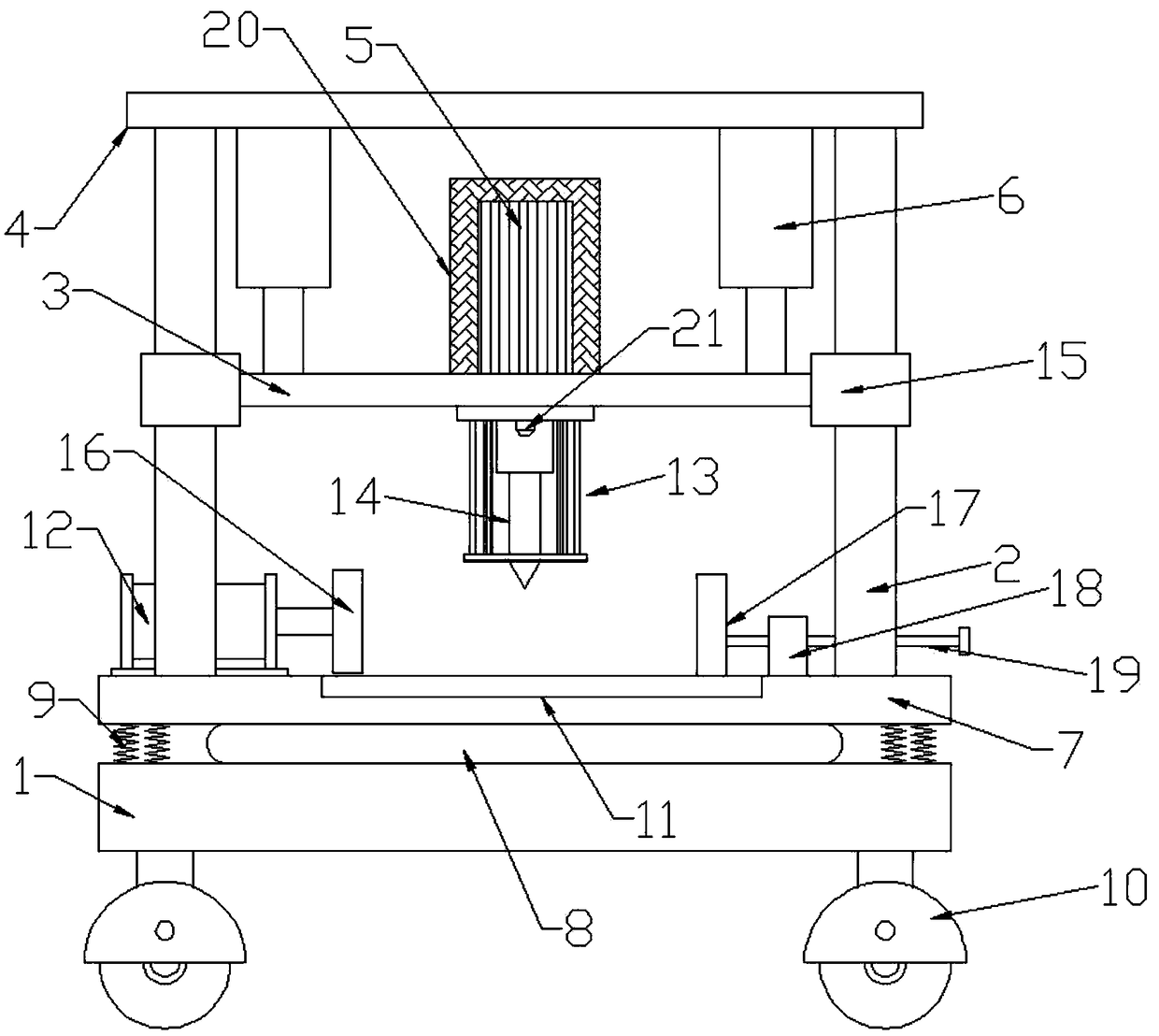

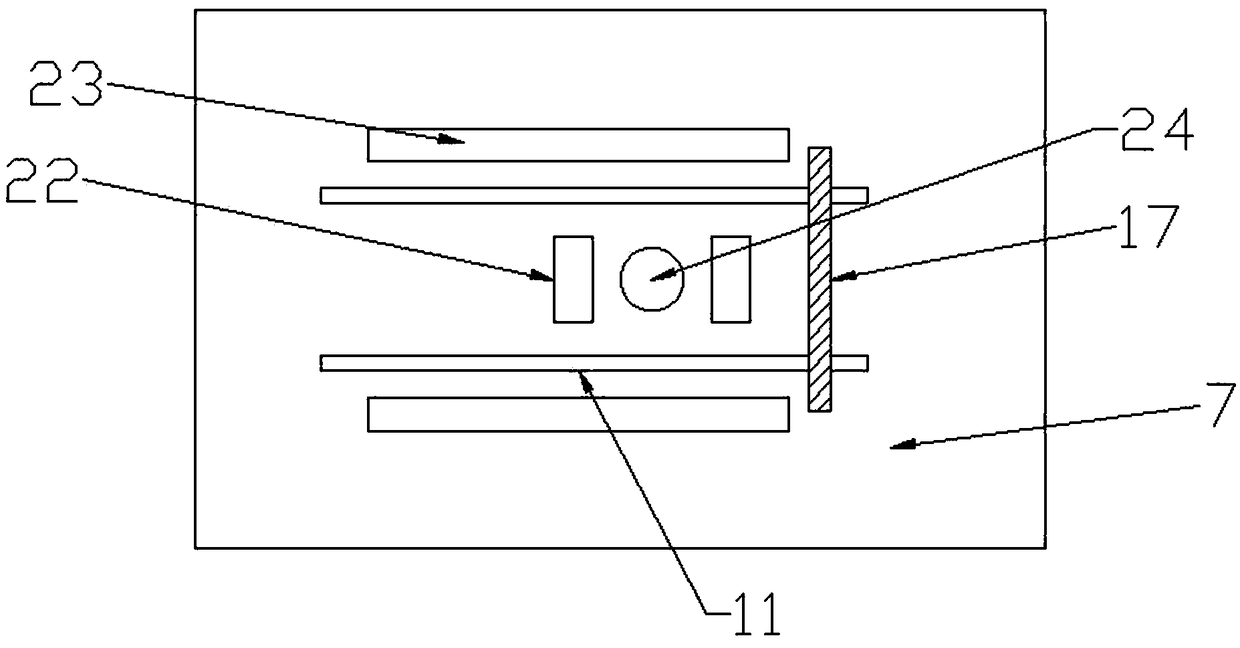

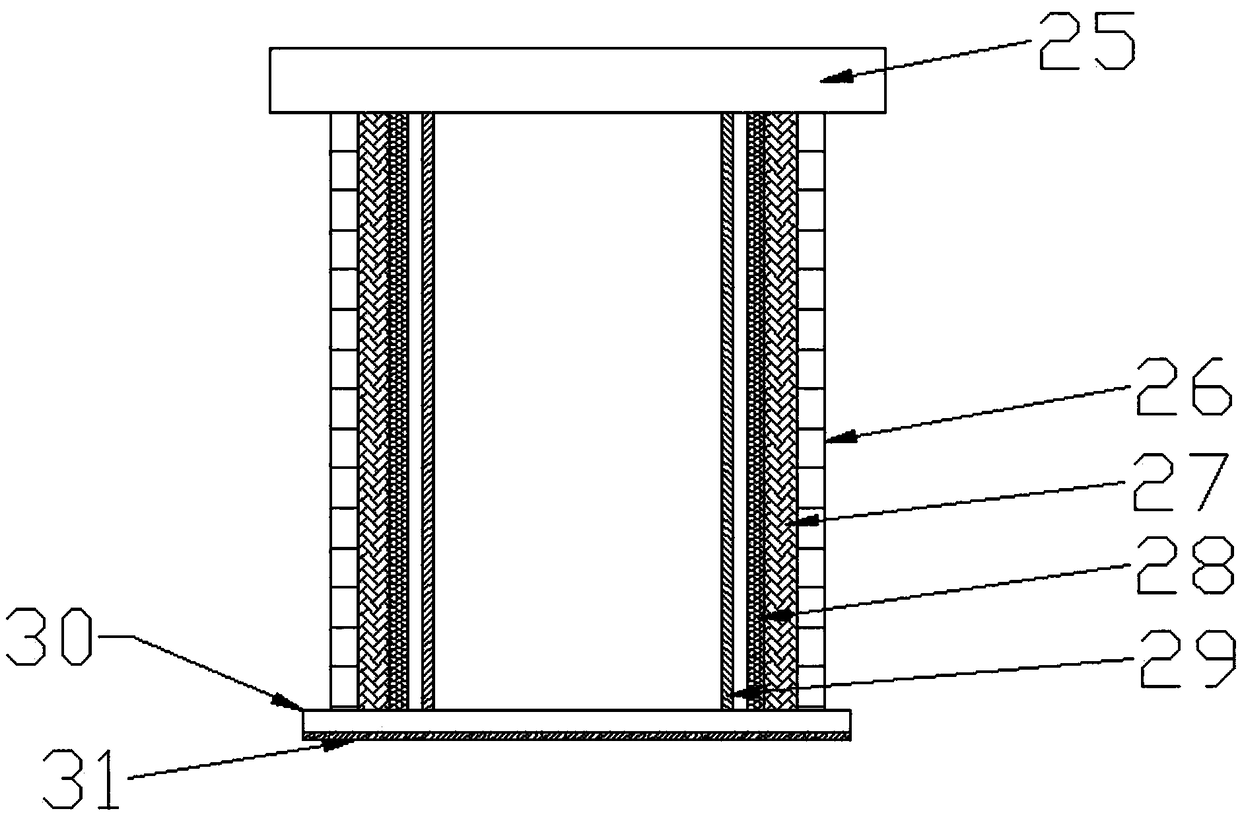

[0018] Please refer to the figure, in the embodiment of the present invention, a kind of drilling equipment for noise-reducing steel processing includes a base 1, a column 2, a lifting beam 3, a top plate 4, a motor 5 and a mounting plate 7; the lower side of the base 1 Rollers 10 are installed to facilitate equipment movement; the mounting plate 7 is located above the base 1, and a shock-absorbing air bag 8 and a shock-absorbing spring 9 are arranged between the base 1 and the mounting plate 7, and the upper and lower parts of the shock-absorbing air bag 8 are respectively glued Attached to the mounting plate 7 and the base 1, the shock absorbing spring 9 is provided with several, the upper end is fixed on the mounting plate 7, the lower end is fixed on the base 1, the mounting plate 7 is supported by the shock absorbing air bag 8 and the shock absorbing spring 9, and the The pressure exerted on the base 1 plays the role of shock absorption and buffering.

[0019] Both ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com