A kind of intelligent manufacturing method of thermoplastic composite metal sandwich panel products

A metal sandwich panel and composite material technology, applied in the field of composite materials, can solve the problems of high manufacturing cost, difficult to adapt to large quantities, large-scale application, long cycle, etc., and achieve the effects of low cost, low density and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

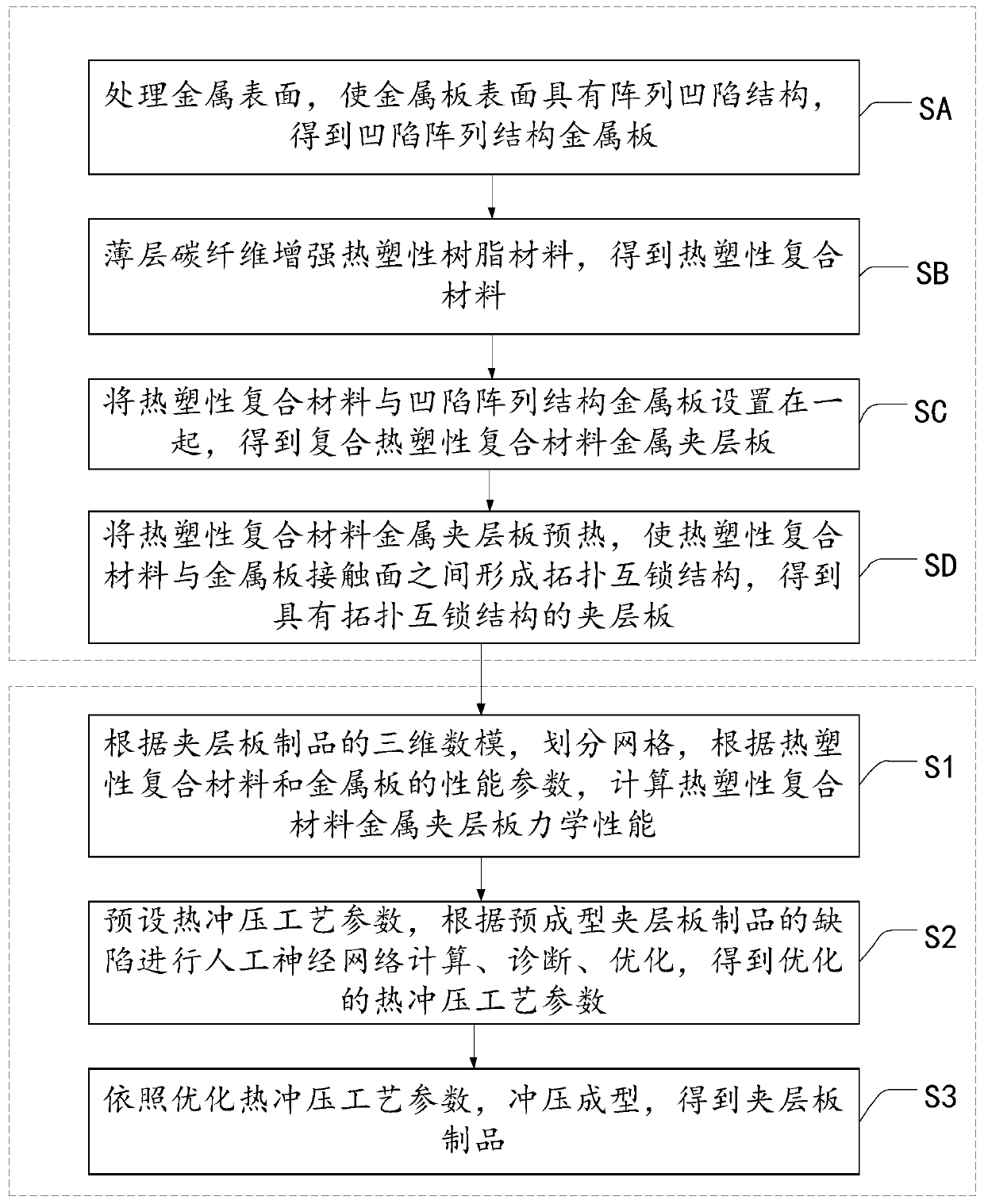

Method used

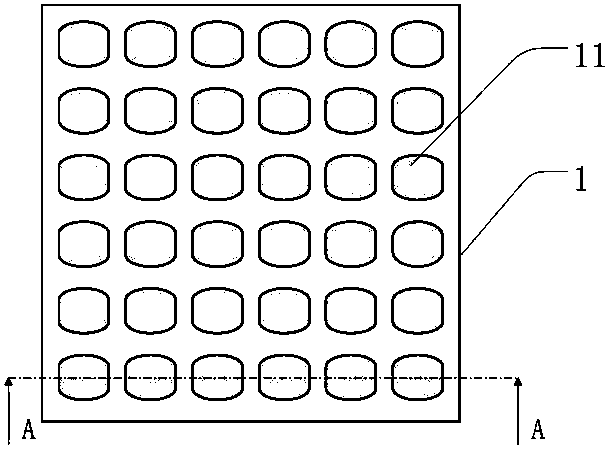

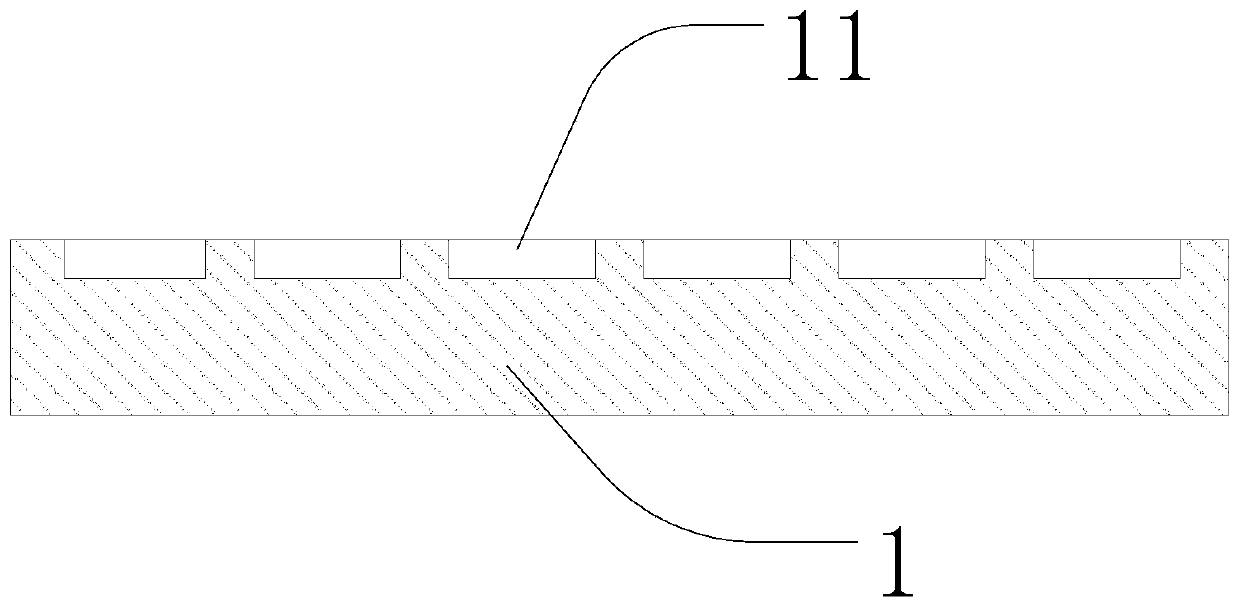

Image

Examples

Embodiment Construction

[0044] The word "embodiment" is used here exclusively, and any embodiment described as "exemplary" is not necessarily to be construed as superior or better than other embodiments. In the performance index test in the embodiment of this method, unless otherwise specified, conventional test methods in this field are adopted. It should be understood that the terminology described in the present invention is only used to describe a specific embodiment, and is not used to limit the disclosed content of the present invention.

[0045]Unless defined otherwise, technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs. Other unspecified raw materials, reagents, test methods and technical means in the present invention all refer to raw materials and reagents commonly used by those skilled in the art, as well as commonly used experimental methods and technical means. The depression mention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com