Wire harness conveying device

A wire feeding device and wire harness technology, which is applied in the field of wire harness processing, can solve the problems of wire harness knotting, lack of tension, and wire harness staggering, and achieve the effects of avoiding impact, avoiding wear or scratches, and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

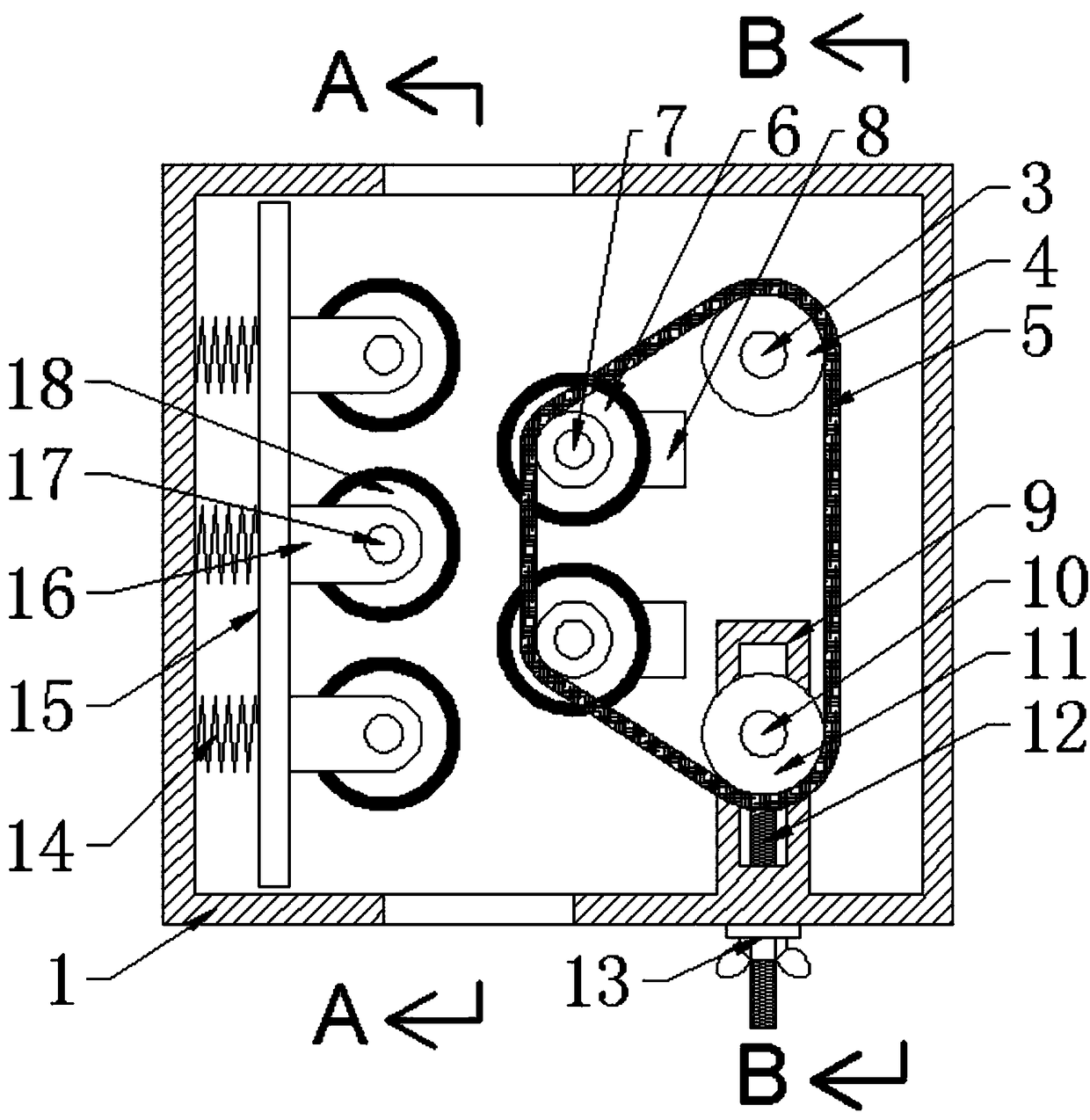

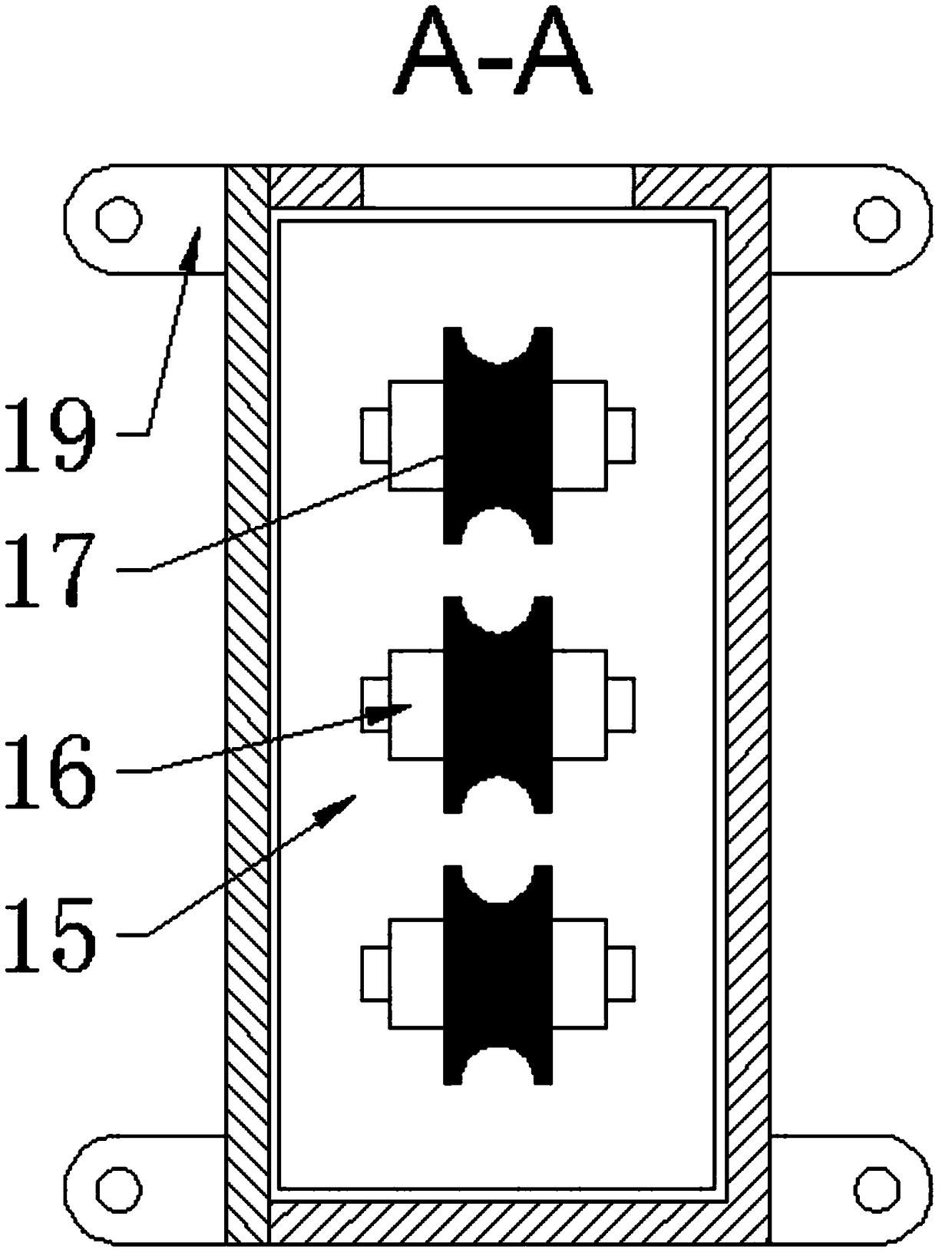

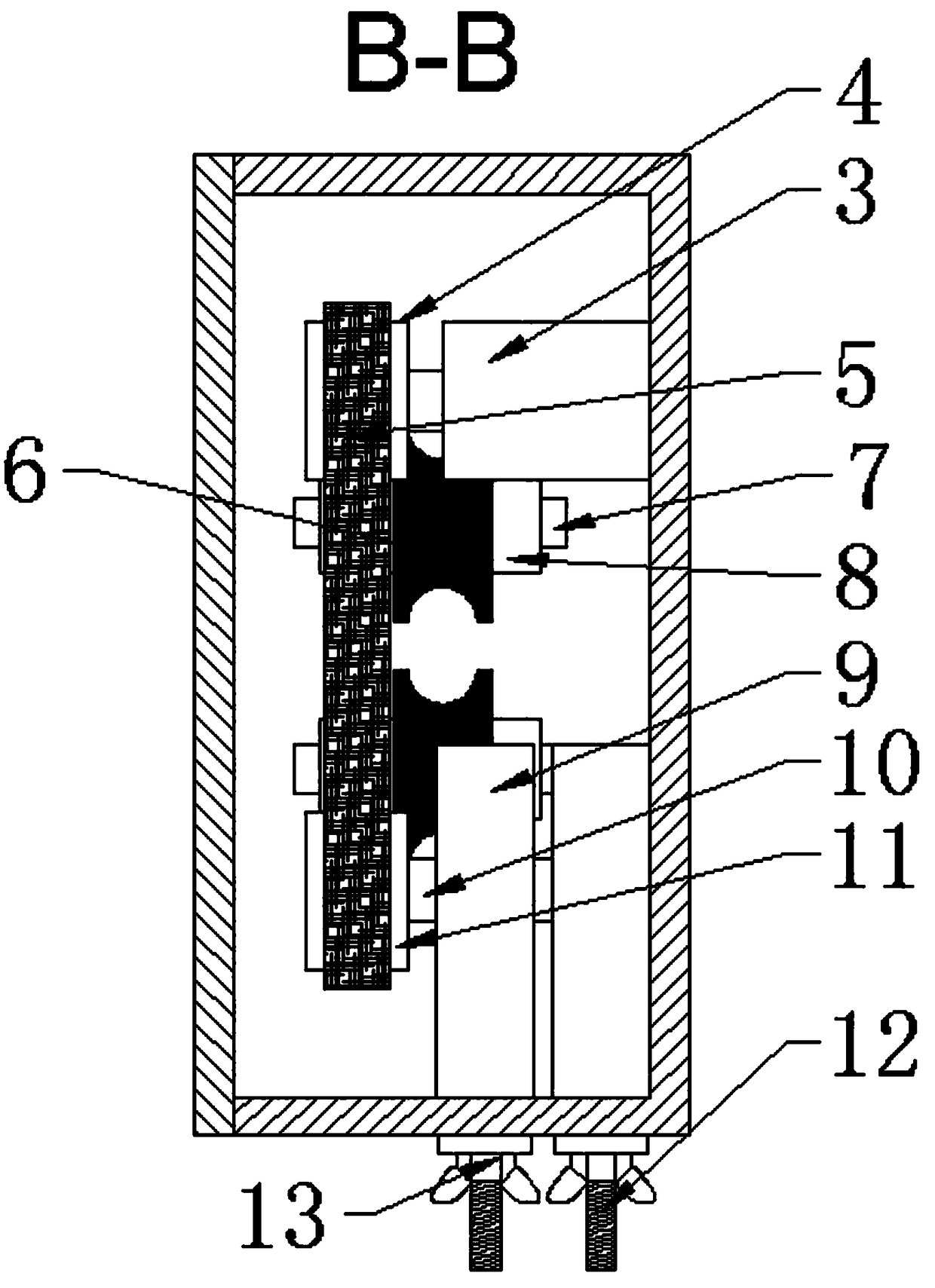

[0024] Such as Figure 1 to Figure 5 As shown, it includes a housing 1 and an adjustment assembly and a drive assembly installed inside the housing 1. The adjustment assembly includes a spring 14 and a movable plate 15. One end of the spring 14 is connected to the housing 1, and the other end is connected to the movable plate 15. connection, the movable plate 15 is provided with a support plate three 16 and a support column three 17, and the support column three 17 is rotatably connected with an auxiliary wire feeding wheel 18 and is installed on the support plate three 16; the drive assembly includes a motor 3 and Drive wheel 4, the motor 3 is vertically installed on the bottom of the housing 1, the drive wheel 4 is installed on the rotating shaft of the motor 3, the drive wheel 4 is connected with the wire feeding pulley 6 and the tension pulley 11 through the belt 5, the shell The left side inside the body 1 is also provided with a support column one 7, a support plate one ...

Embodiment 2

[0031] Such as Figure 1 to Figure 5 As shown, it includes a housing 1 and an adjustment assembly and a drive assembly installed inside the housing 1. The adjustment assembly includes a spring 14 and a movable plate 15. One end of the spring 14 is connected to the housing 1, and the other end is connected to the movable plate 15. connection, the movable plate 15 is provided with a support plate three 16 and a support column three 17, and the support column three 17 is rotatably connected with an auxiliary wire feeding wheel 18 and is installed on the support plate three 16; the drive assembly includes a motor 3 and Drive wheel 4, the motor 3 is vertically installed on the bottom of the housing 1, the drive wheel 4 is installed on the rotating shaft of the motor 3, the drive wheel 4 is connected with the wire feeding pulley 6 and the tension pulley 11 through the belt 5, the shell The left side inside the body 1 is also provided with a support column one 7, a support plate one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com