Hollow graphene fiber as well as preparation method thereof and application

A graphene fiber and hollow technology, which is applied in the field of material science, can solve the problems that hollow fibers cannot be continuous and batch, and achieve the effect of low production cost and high output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The object of the present invention is achieved by the following technical scheme: a kind of preparation method of many hollow graphene fibers comprises the following steps:

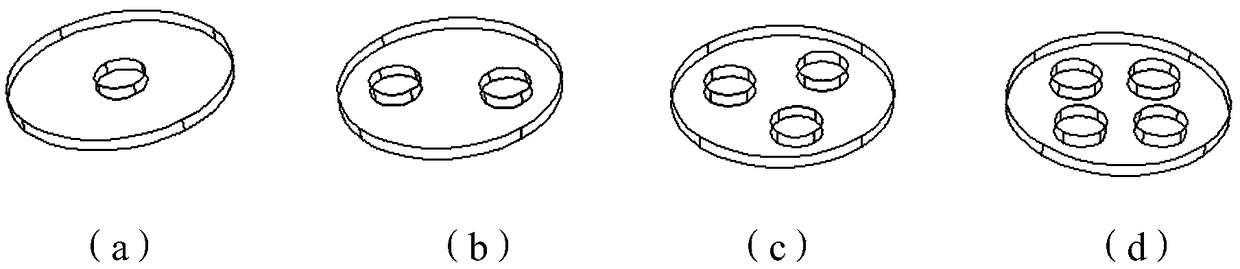

[0035] (1) Prepare circular hollow SU-8 disc substrates (such as figure 1 shown).

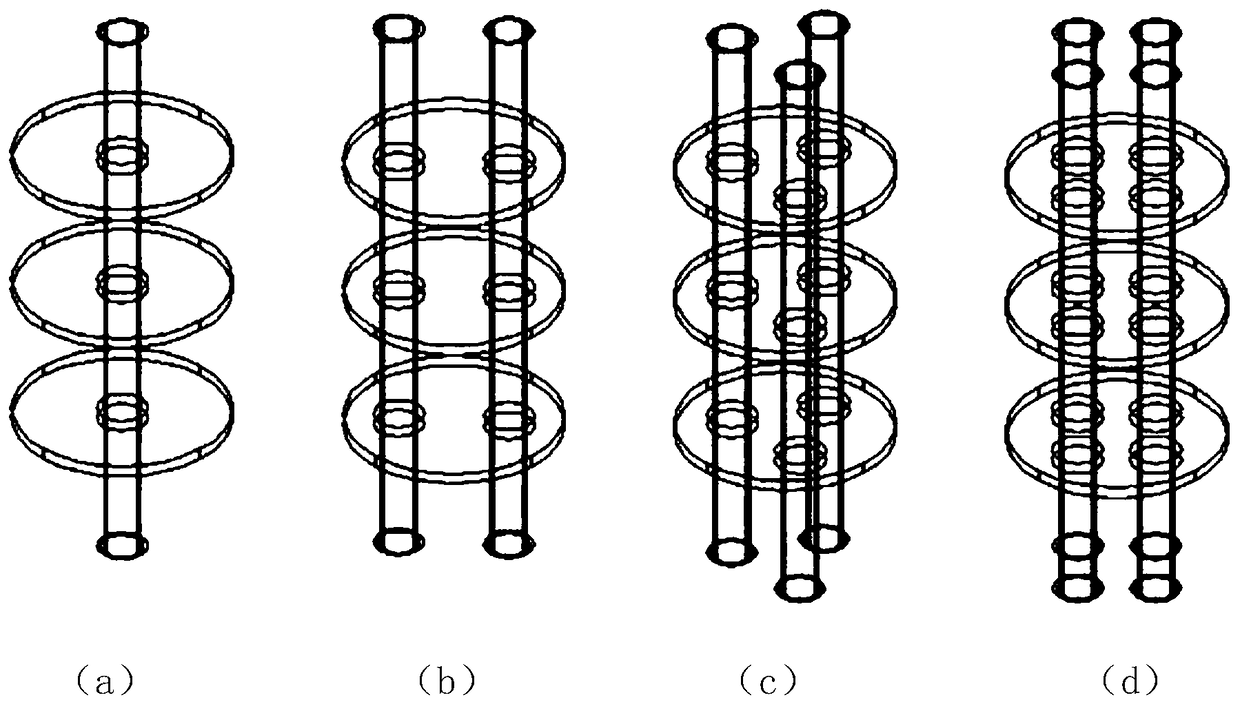

[0036] (2) Assemble the SU-8 disc substrate obtained in step (1) and the thin glass capillary A matching its circular hollow size, and use quick-drying glue to contact the SU-8 disc substrate with the thin glass capillary places to fix (such as figure 2 shown).

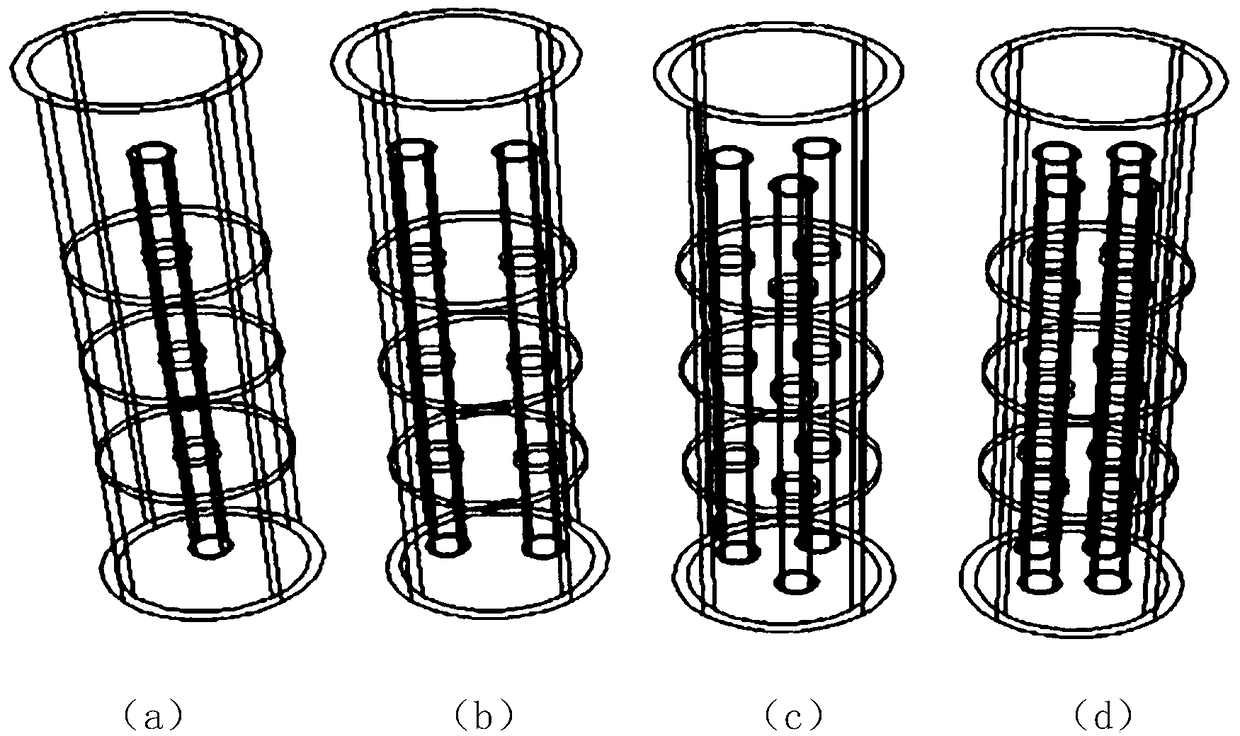

[0037] (3) Insert the assembly of the SU-8 wafer substrate and the thin glass capillary obtained in step (2) into the thick glass capillary B, and fix it with quick-drying adhesive.

[0038] (4) Connect the sampling tube on different capillaries to obtain the spinning device (such as image 3 shown). One of the ends of the spinning device is set as the S end, and the other end is set as the N end; the sampling tubes A are respectively connected to the ...

Embodiment 1

[0049] This embodiment is a preparation method for a single hollow graphene fiber with a cross section, comprising the following steps:

[0050] (1) Utilize photolithography to prepare a single hollow SU-8 wafer on a silicon wafer, such as figure 1 (a), and peel them off from the silicon wafer.

[0051] (2) Assemble the SU-8 disc obtained in step (1) and the thin glass capillary A matching its circular hollow size, so that all the boundary parts of the circular holes on the SU-8 disc are fixed to the capillary The outer wall of A, and make the SU-8 disc perpendicular to the capillary A, and use quick-drying glue to fix the place where the SU-8 disc contacts the thin glass capillary A, such as figure 2 (a) shown.

[0052] (3) Insert the assembly of SU-8 disc and thin glass capillary A obtained in step (2) into the thick glass capillary B, so that all the boundary parts of the substrate are fixed to the inner wall of capillary B, and the SU-8 The disc is perpendicular to cap...

Embodiment 2

[0062] The present embodiment is the preparation method of the graphene fiber that cross section is double hollow, comprises the following steps:

[0063] (1) Utilize the photolithography method to prepare the SU-8 disc with double hollow on the silicon wafer, as figure 1 (b), and peel them off from the silicon wafer.

[0064] (2) Assemble the SU-8 disc obtained in step (1) and the thin glass capillary A matching its circular hollow size, so that all the boundary parts of the circular holes on the SU-8 disc are fixed to the capillary The outer wall of A, and make the SU-8 disc perpendicular to the capillary A, and use quick-drying glue to fix the place where the SU-8 disc contacts the thin glass capillary A, such as figure 2 (b) shown.

[0065] (3) Insert the assembly of SU-8 disc and thin glass capillary A obtained in step (2) into the thick glass capillary B, so that all the boundary parts of the substrate are fixed to the inner wall of capillary B, and the SU-8 The disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com