Prefabricated assembled UHPC side anti-collision guardrail grouting connecting structure

A prefabricated assembly and grouting connection technology, applied in bridge parts, bridge materials, bridges, etc., can solve the problems of high degree of danger and complicated operation, and achieve the effect of high degree of assembly, convenient construction and convenient prefabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

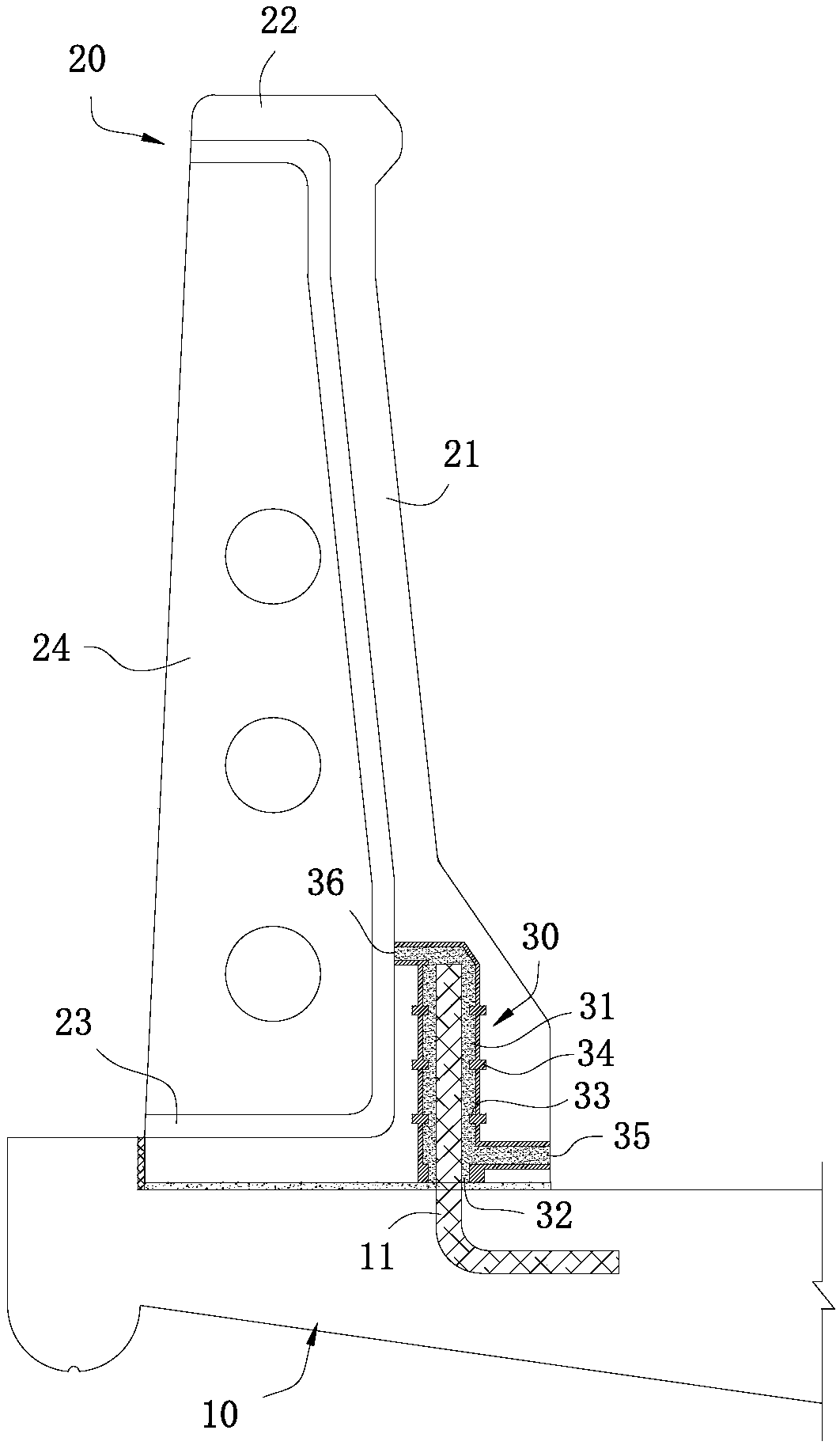

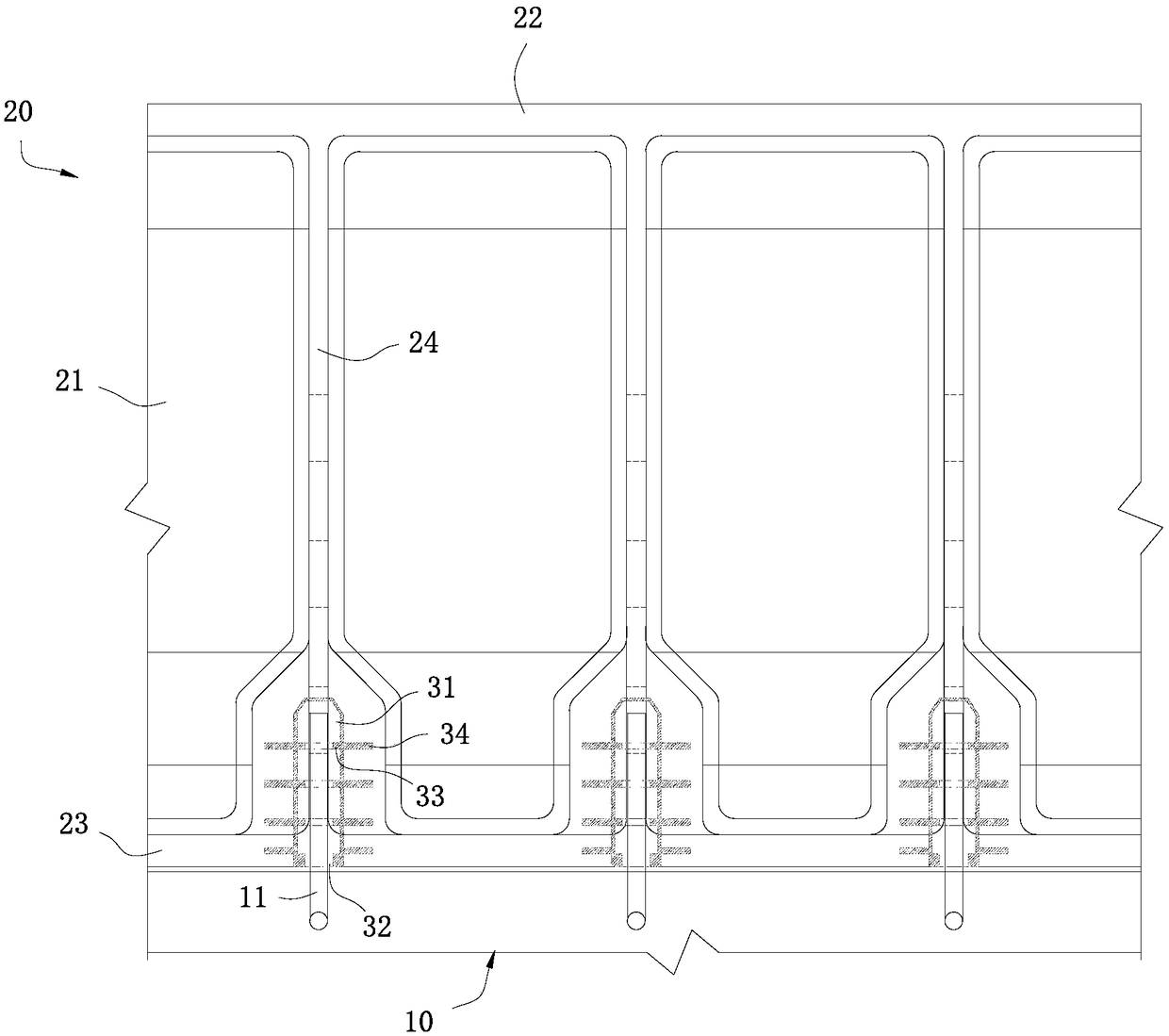

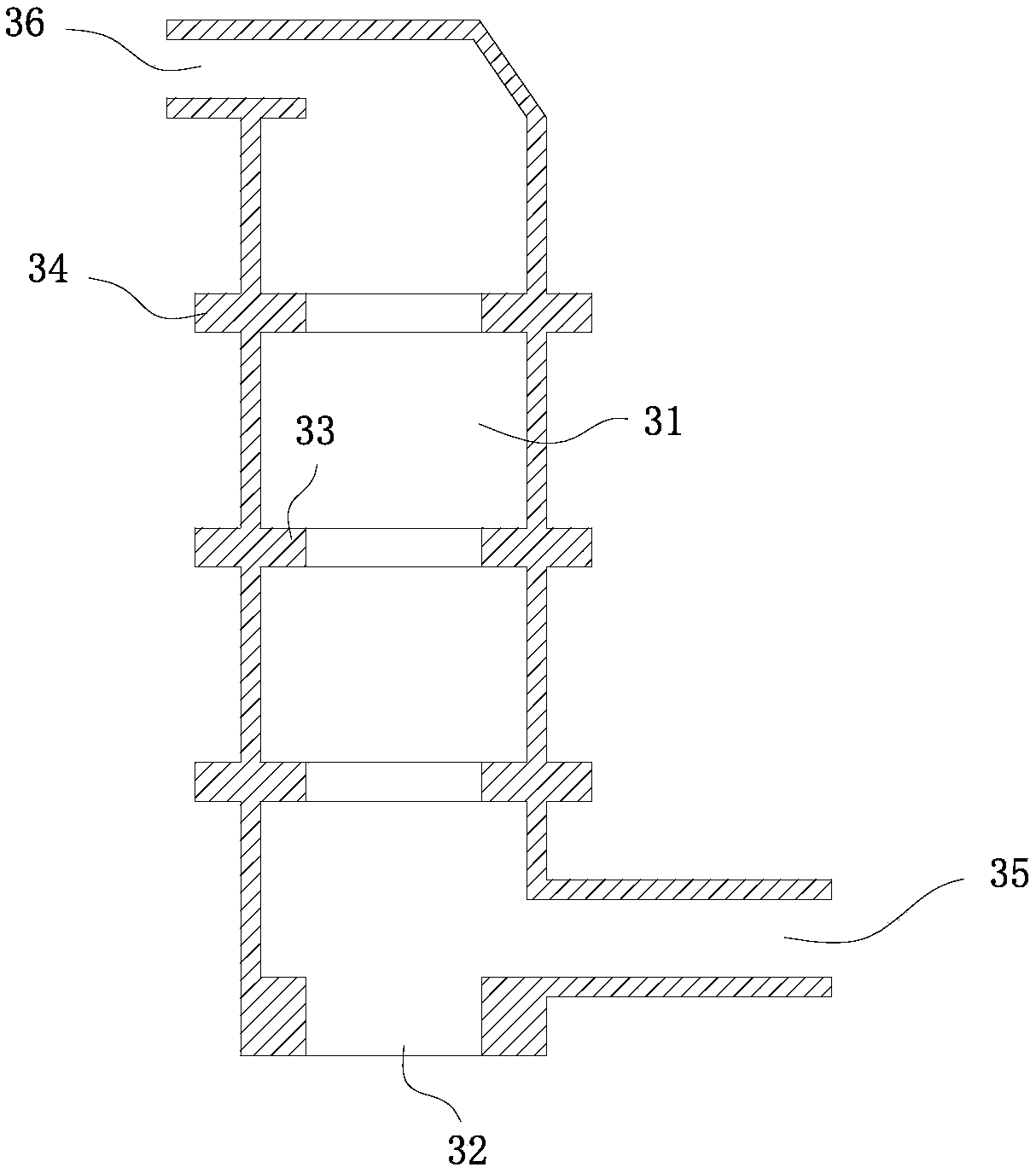

[0022] Reference Figure 1 to Figure 4 , The prefabricated and assembled UHPC side impact barrier grouting connection structure of the present invention includes a main beam wing plate 10 and a UHPC impact barrier 20. The main beam wing plate 10 extends with connecting steel bars 11, and the bottom of the UHPC impact barrier 20 is embedded inside There is a grouting sleeve 30, the inside of the grouting sleeve 30 is hollow with a pouring chamber 31, and the bottom of the grouting sleeve 30 has an opening 32. When the grouting sleeve 30 is pre-buried in the UHPC crash barrier 20, the opening 32 of the grouting sleeve 30 It is flush with the bottom wall surface of the UHPC anti-collision barrier 20, and the opening 32 is for the connecting steel bar 11 to be inserted into the pouring chamber 31. The length of the connecting steel bar 11 extending into the pouring chamber 31 is not less than 9 times the diameter of the connecting steel bar. At least three internal shear keys 33 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com