Suspended formwork construction method of tool-type template at height difference position of template surface

A construction method and tool-based technology, which is applied to the connection of formwork/formwork/work frame, the preparation of building components on site, construction, etc., can solve the problem of poor control of the elevation of the hanging form, damage to the formwork of the hanging form, and difficult peeling of concrete. and other problems, to achieve the effect of convenient operation, convenient production and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The technological process of the construction method of the tool-type formwork hanging mold at the height difference of the board surface of the present invention:

[0033] Hanging formwork material preparation→hanging formwork blanking and processing→hanging formwork splicing→site setting out→hanging formwork construction→correction and reinforcement→concrete pouring→formwork removal→cleaning and maintenance.

[0034] The tool-type formwork hanging formwork construction method at the level difference of the board surface of the present invention comprises the following steps:

[0035] a. Make hanging formwork template

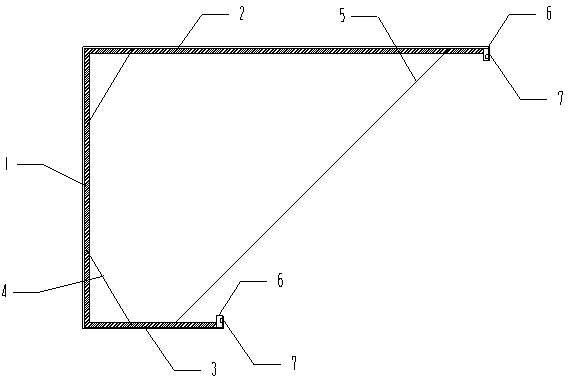

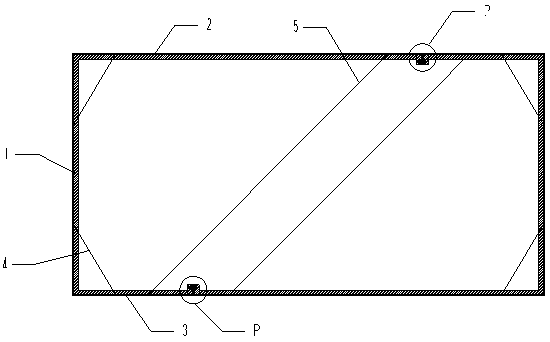

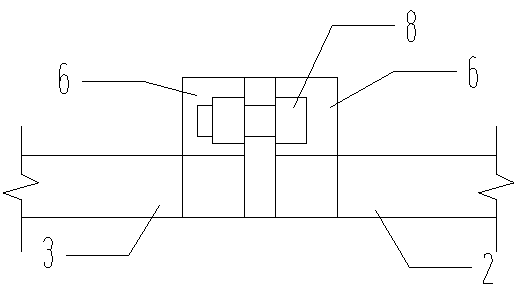

[0036] see now figure 1 , figure 1 It is a schematic diagram of the structure of the asymmetric U-shaped bracket of the embodiment of the present invention. According to the size of the height difference between the bathroom, the kitchen, and the balcony, an asymmetric U-shaped bracket is made with angle iron. The bracket is equipped with a first rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com