Interlocking check nut

A technology of locknuts and nuts, which is applied in the field of fixing frequently vibrating components and fixing components, and can solve the problems that locknuts cannot be interlocked, inconvenient to manufacture and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

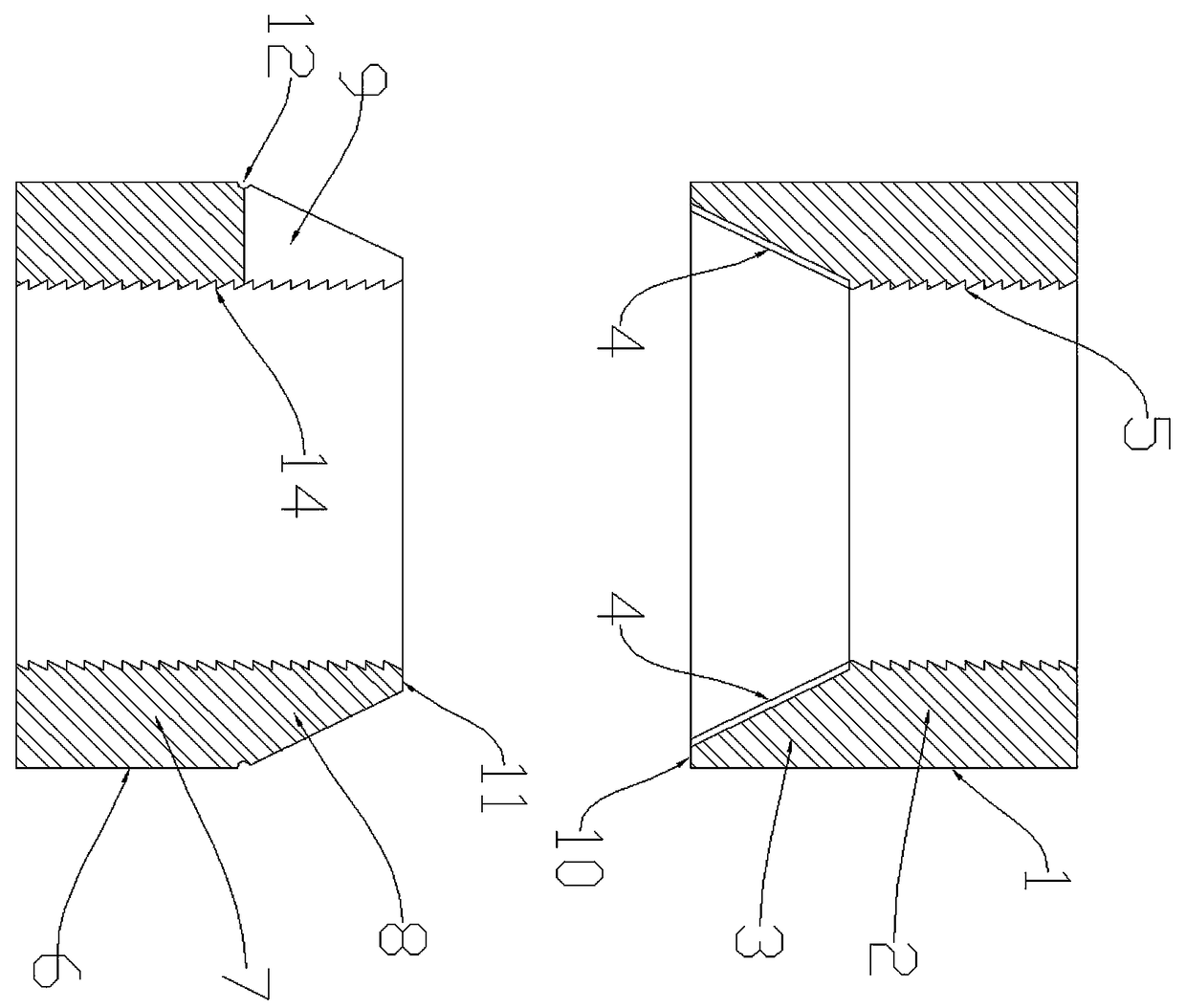

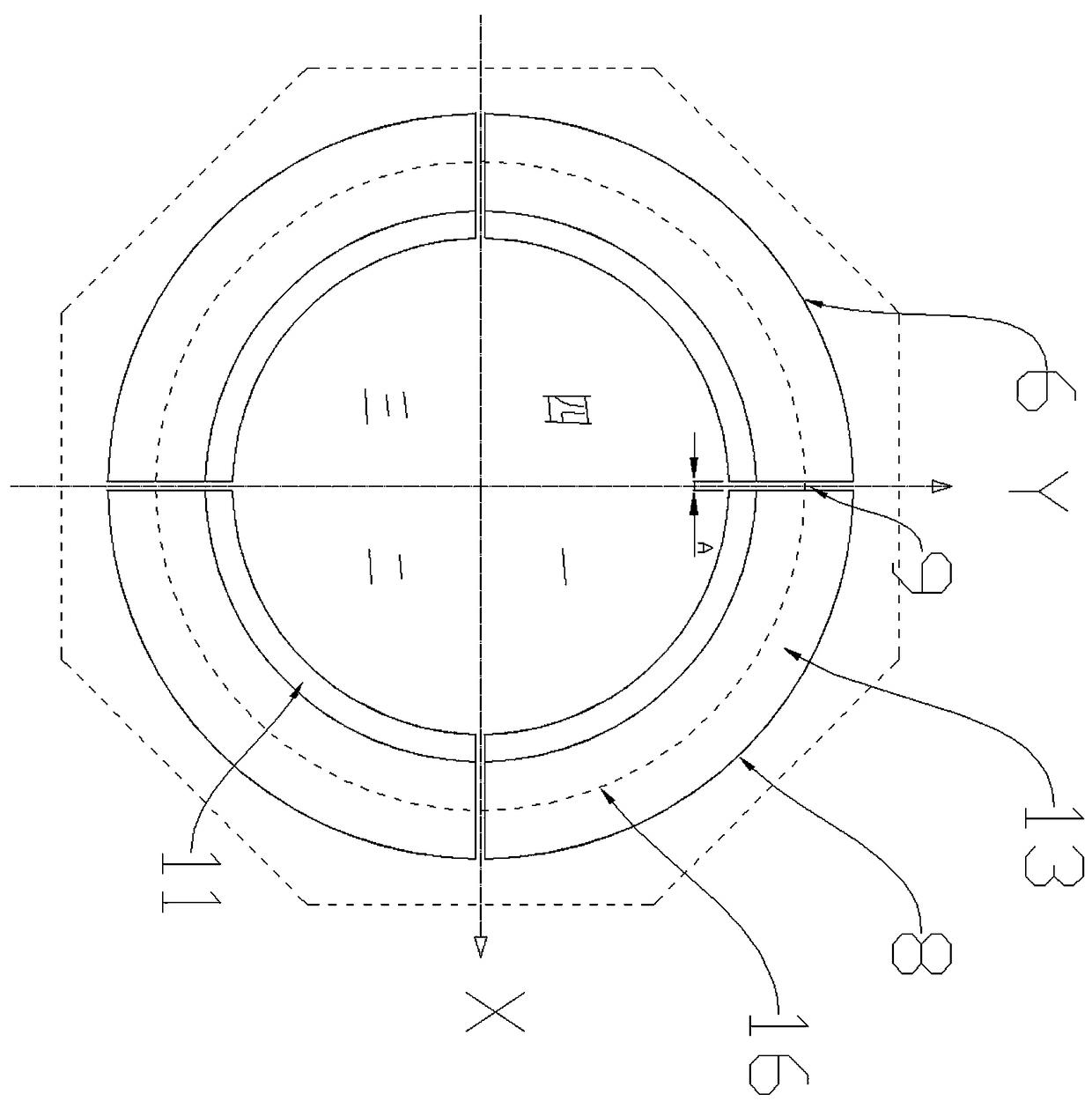

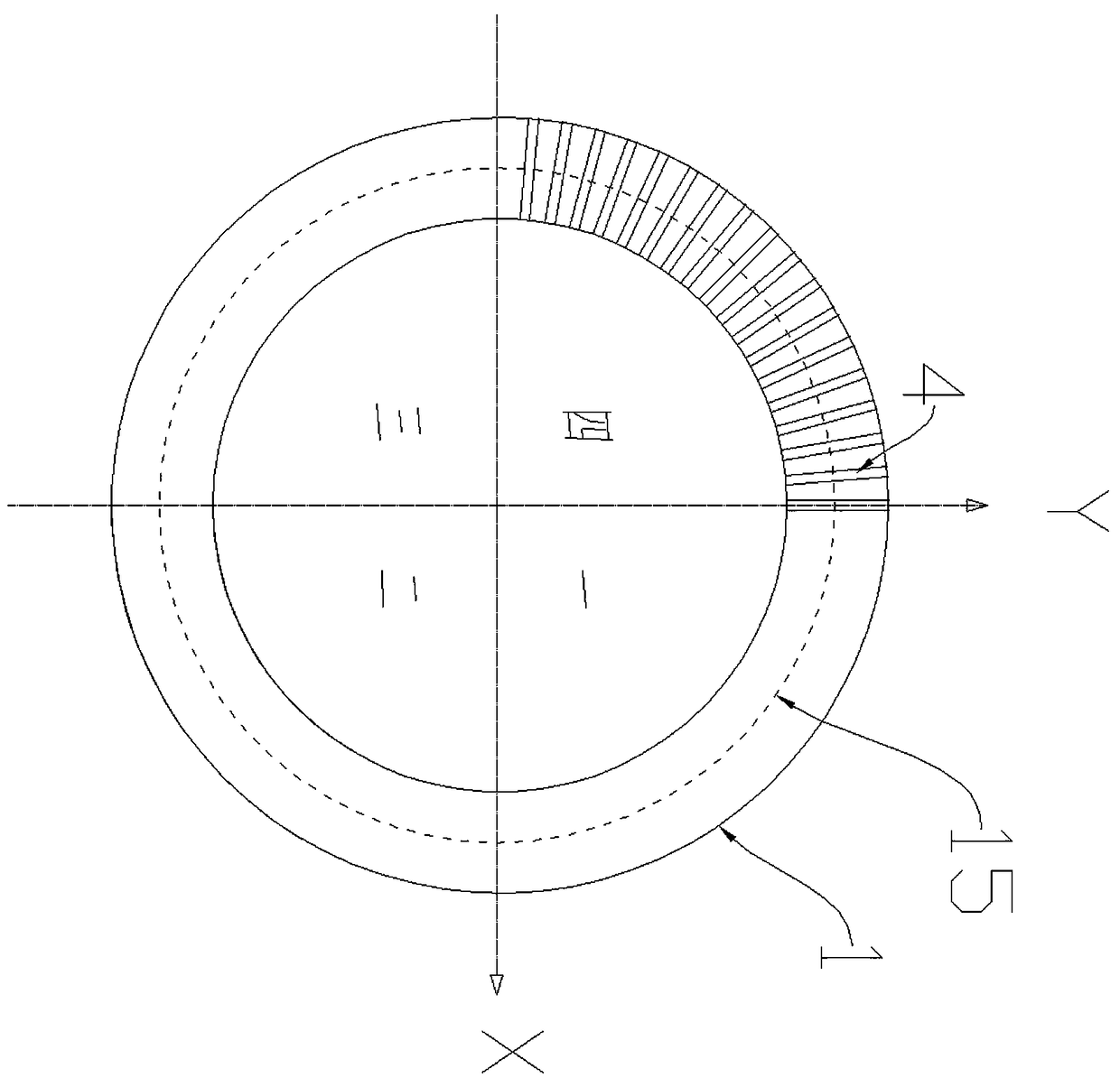

[0014] see Figure 1 to Figure 9 , first illustrate the arrangement of a plurality of strip-shaped convex ribs 4, assuming that the number of clips 13 is N, N is an even number, the number of the same groove 9 is also N, the width of the groove 9 is A, and a plurality of clips 13 are formed The radius of the imaginary circle 16 at the center point of the outer surface of the conical ring is R, and the arc length of the center point of each clip 13 is C, then C=2∏R / N-A, and it is assumed that the extrusion part 3 of the nut A1 M convex ribs 4 are arranged on the inner surface of the conical ring corresponding to the arc length C of the clip 13, and the virtual circle radius of the center point of the inner surface of the conical ring of the extruded part 3 of the nut A1 is R'. When nut A1 and nut B6 are processed, R=R', the distance between the central axes of adjacent convex ribs 4 is B, then B=C / M, and the projection circle of the inner surface of the conical ring of the extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com