Atmospheric flash tank vapour-discharging energy-saving environment-friendly treating system

An atmospheric expansion vessel, energy saving and environmental protection technology, applied in the field of boilers, can solve problems such as affecting the normal use of equipment around the boiler, the normal life of surrounding residents, affecting the overall environmental quality, and increasing humidity, eliminating white smoke plumes and improving utilization efficiency. , to achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

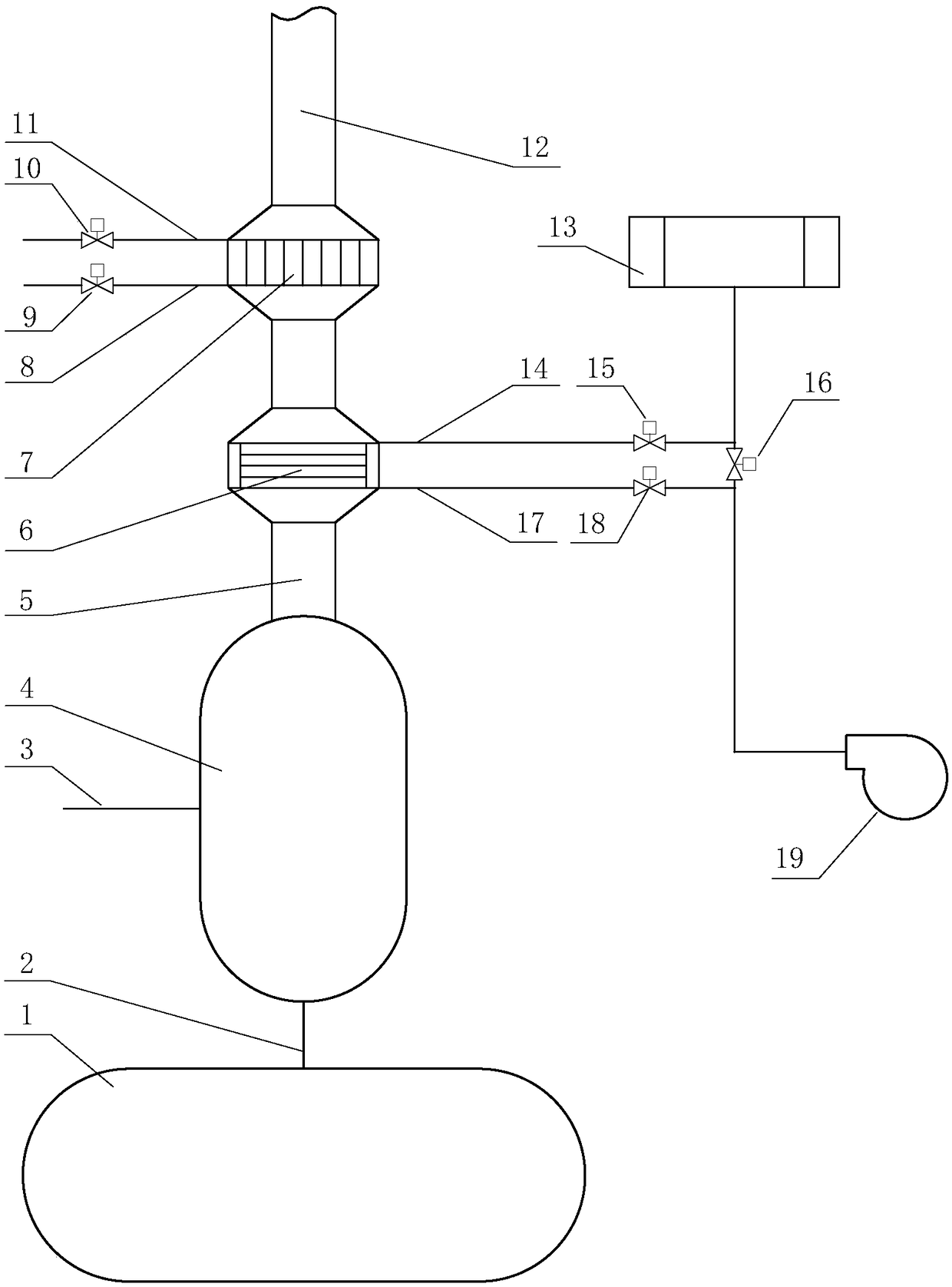

[0017] The present invention is described in further detail below in conjunction with accompanying drawing:

[0018] refer to figure 1 , the atmospheric expansion vessel exhaust steam energy-saving and environmental protection treatment system of the present invention comprises a drainage water input pipeline 3, an expansion vessel 4, a condensed water tank 1, an exhaust steam condenser 6, an exhaust steam heater 7, a steam output pipeline 12, and a fan 19 , an air preheater 13, a high-temperature medium input pipeline 8 and a high-temperature medium output pipeline 11; the drain water input pipeline 3 communicates with the inlet on the side of the middle part of the expander 4, and the outlet at the bottom of the expander 4 communicates with the inlet of the condensed water tank 1, The outlet at the top of the expander 4 is connected to the heat release side inlet of the exhaust steam condenser 6, and the heat release side outlet of the exhaust steam condenser 6 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com