Direct air-cooling system for optimization of flow distribution of steam

A steam flow and optimized distribution technology, which is applied to steam/steam condensers, lighting and heating equipment, etc., can solve the problems of uneven distribution of steam flow, uneven temperature of condensed water, and incomplete cooling of places with high flow of tube bundles. Achieve the effects of reducing the stress asymmetry of the tube bundle, improving the thermal load matching ability, and improving the antifreeze summer ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

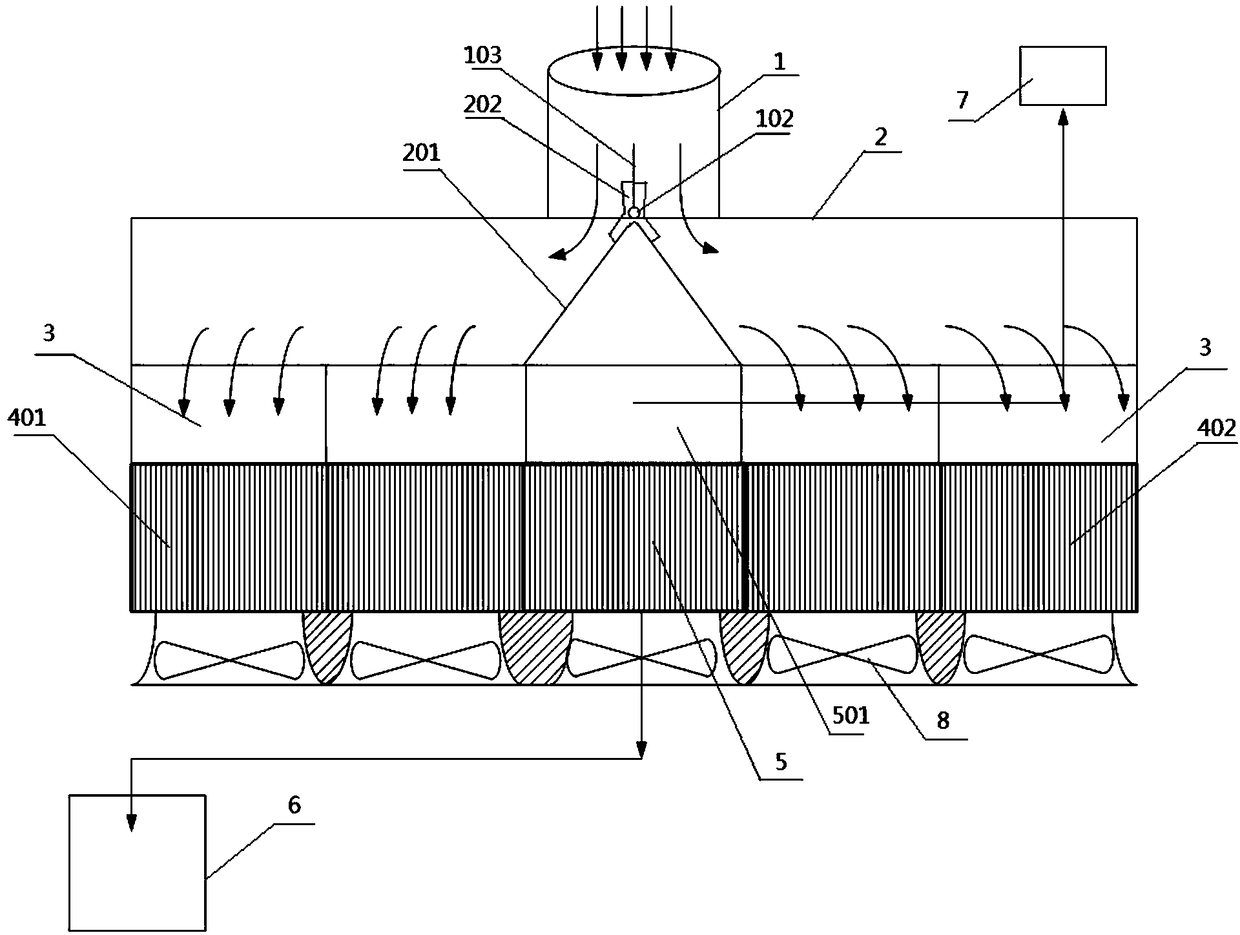

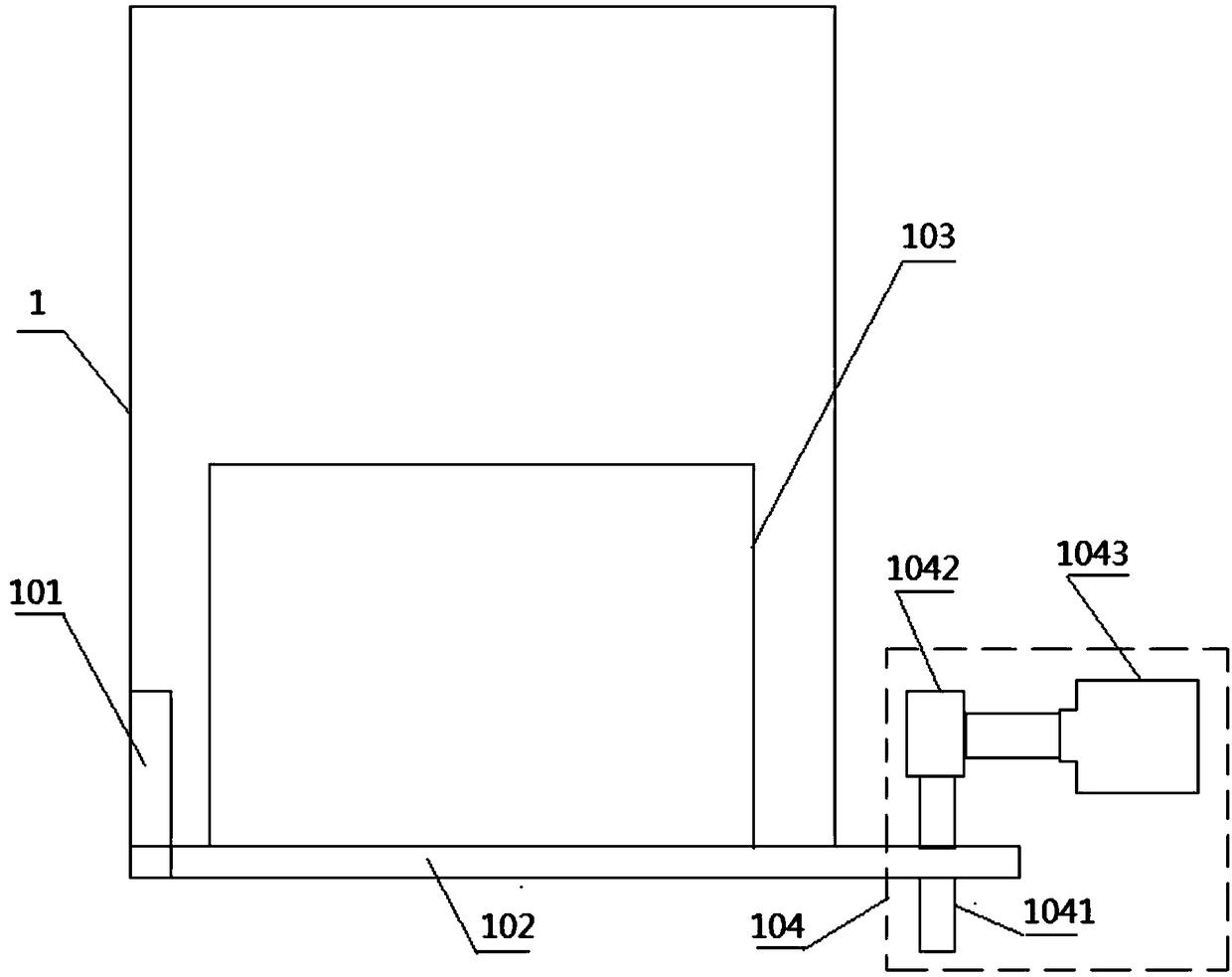

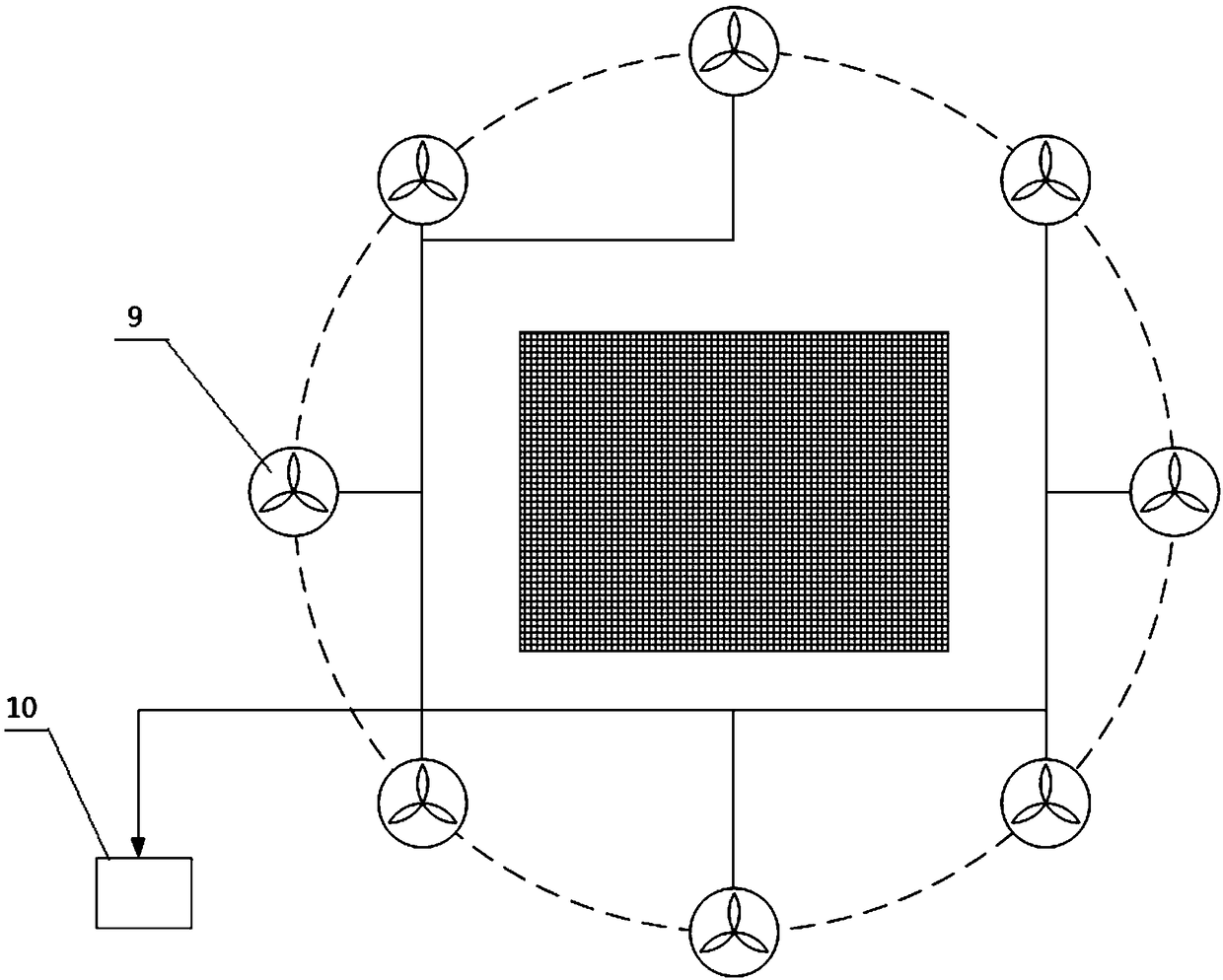

[0030] refer to figure 1 and figure 2 , the direct air cooling system for optimizing the distribution of steam flow in the present invention includes a vertically arranged steam introduction pipe 1, the lower end of the steam introduction pipe 1 is connected with a horizontally arranged steam distribution pipe 2, and the lower end of the steam distribution pipe 2 is connected with a plurality of buffer covers 3 , a plurality of buffer covers 3 are symmetrically arranged at both ends of the steam distribution pipe 2; the lower end of each buffer cover 3 is correspondingly connected with a set of tube bundles 4 in the downstream area; multiple sets of tube bundles 4 in the downstream area include a windward side tube bundle 401 and a leeward side tube bundle 402 , a tube bundle 5 in the upstream side tube bundle 401 and a tube bundle 402 on the leeward side is provided in the middle; a steam header 501 is connected to the upper end of the tube bundle 5 in the countercurrent zon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com