COA array substrate, preparation method thereof and display device

An array substrate and array technology, applied in the fields of COA array substrates, preparation methods and display devices, can solve the problems of ITO residue and lack of planarization, and achieve the effects of reducing conduction resistance, reducing the risk of open circuit, and avoiding crossover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

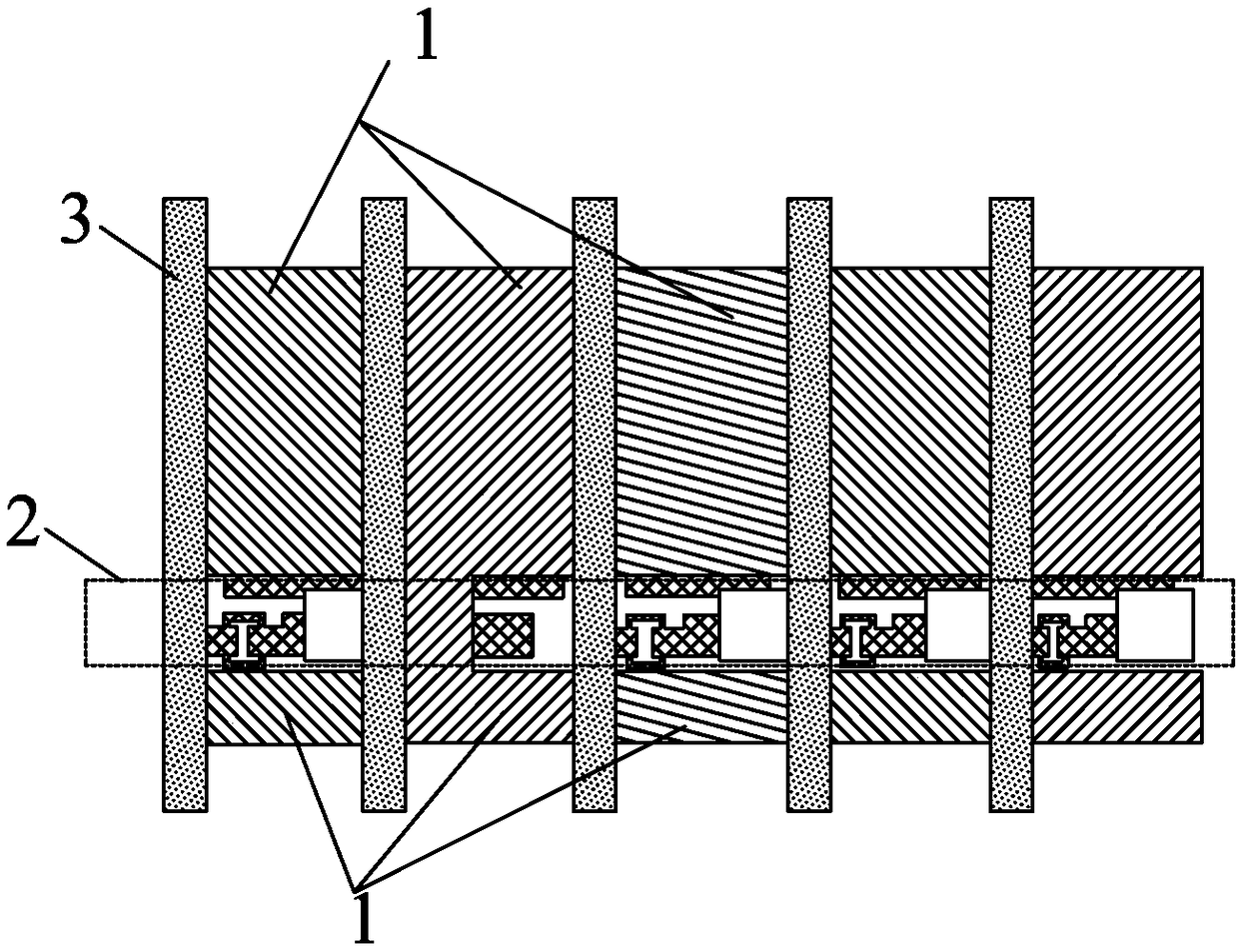

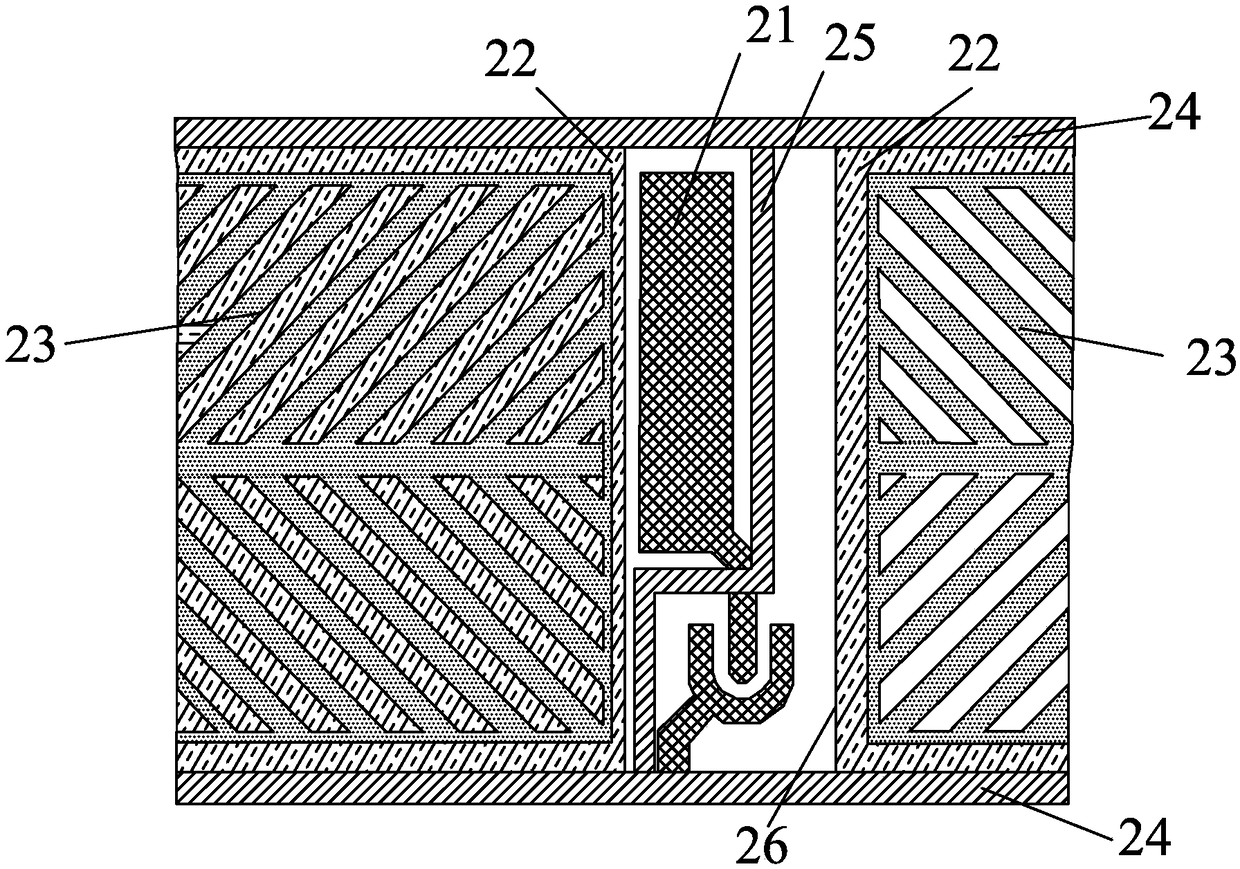

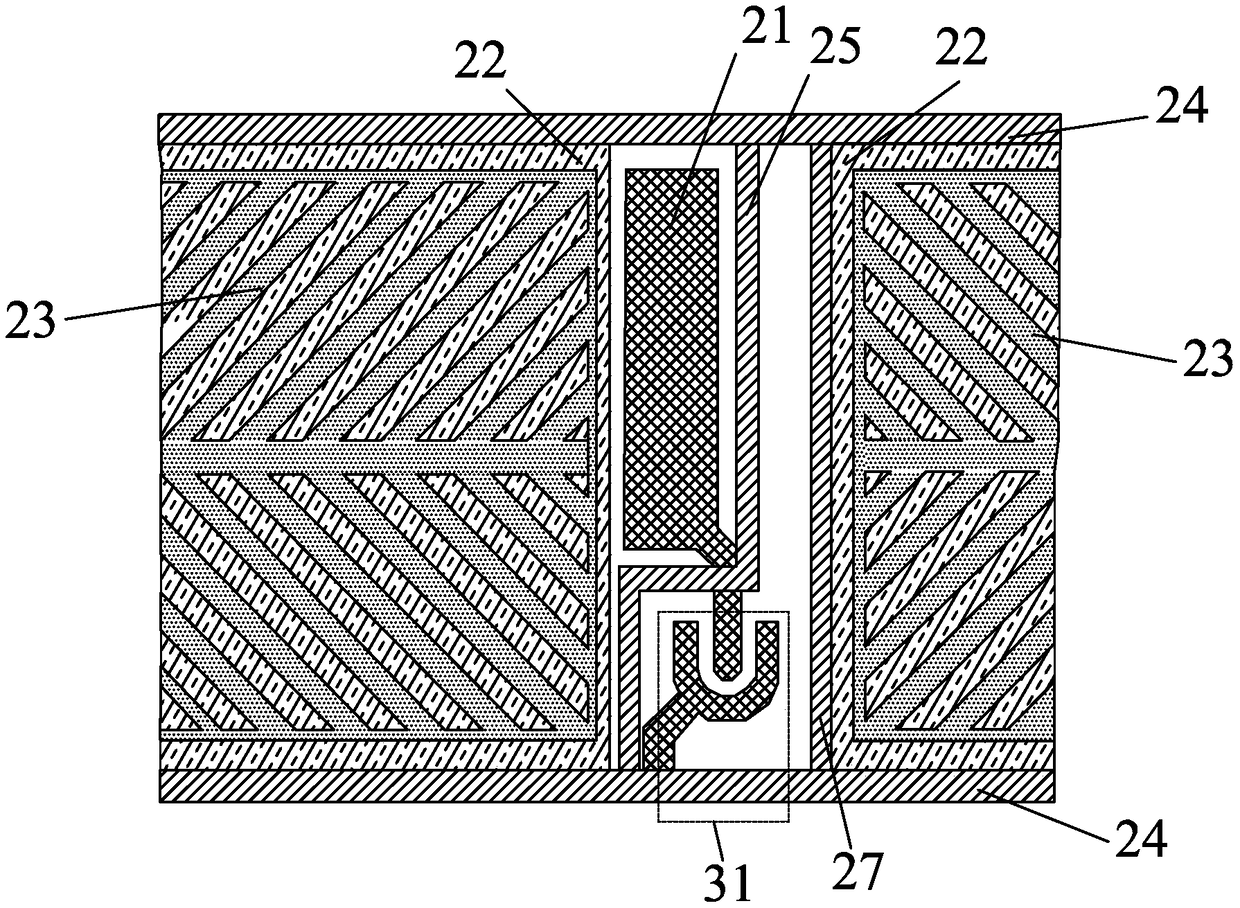

[0035] see image 3 , which is a schematic plan view of a preferred embodiment of the COA array substrate of the present invention. The COA array substrate mainly includes: a TFT array arranged on the substrate, including gate lines (not shown) and data lines (not shown), the entire surface is covered with a first insulating protective layer; The color filter layer pattern 22, i.e. RGB color resistance; the color filter layer pattern 22 is dug in the gate line area, and the gate line area is not only provided with a gate line, but also provided with a TFT structure 31 drain electrode or storage For the source and drain metal block patterns 21 of the capacitor, black spacers can be made later, and the color filter layer patterns 22 are connected and overlapped in the data line area; the second insulating protective layer is subsequently deposited, and then the ITO conductive electrode pattern is prepared.

[0036] The ITO conductive electrode pattern mainly includes: the pixel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com