Liquid injection machine having long standing time for soft pack lithium battery

A soft-pack lithium battery and resting time technology, applied in battery pack components, non-aqueous electrolyte batteries, non-aqueous electrolyte batteries, etc., can solve the problems of low production efficiency, extended production line length, and large plant area. , to achieve the effect of facilitating the discharge of air bubbles, improving production efficiency and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to describe the technical content, structural features, and achieved effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

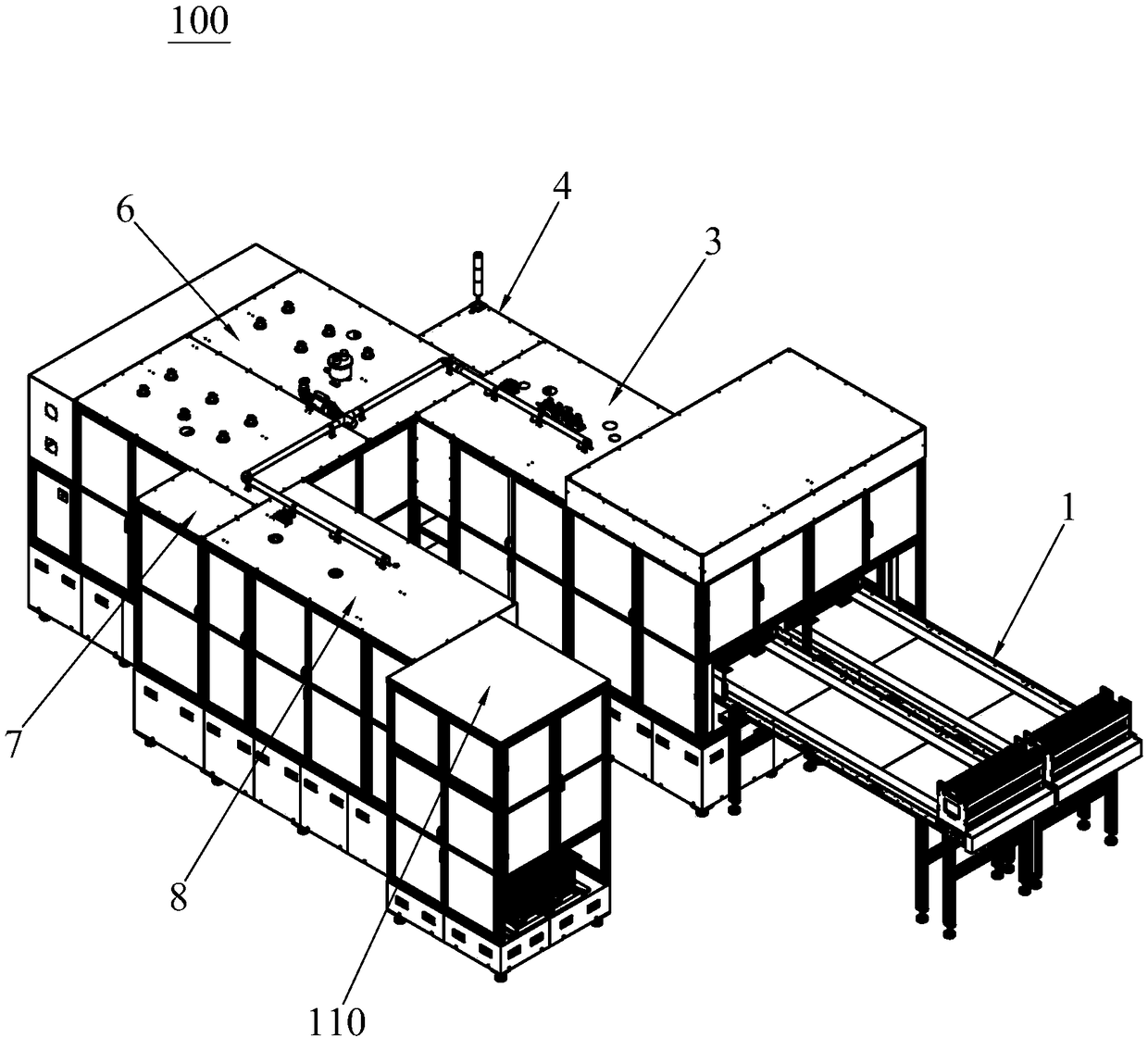

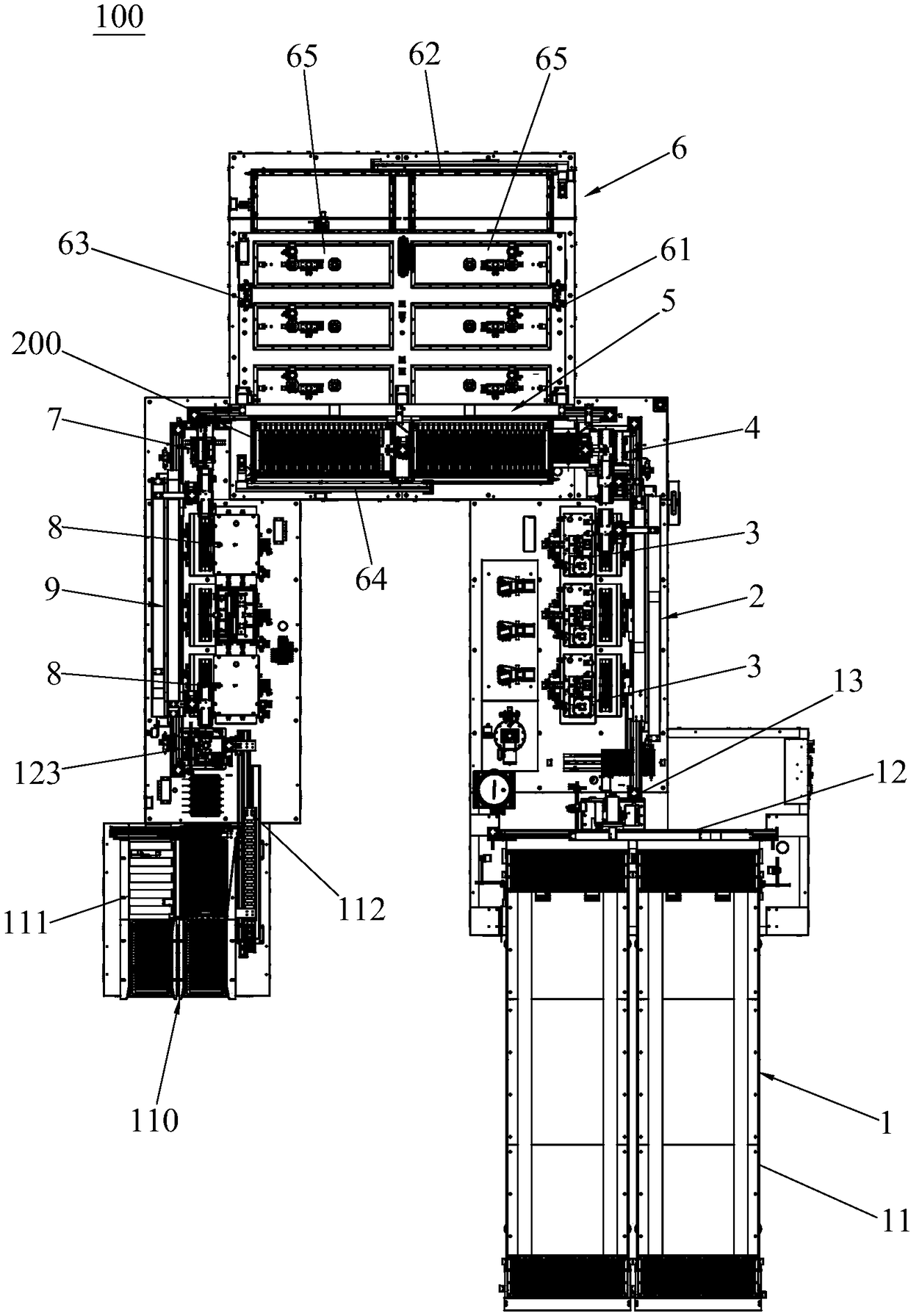

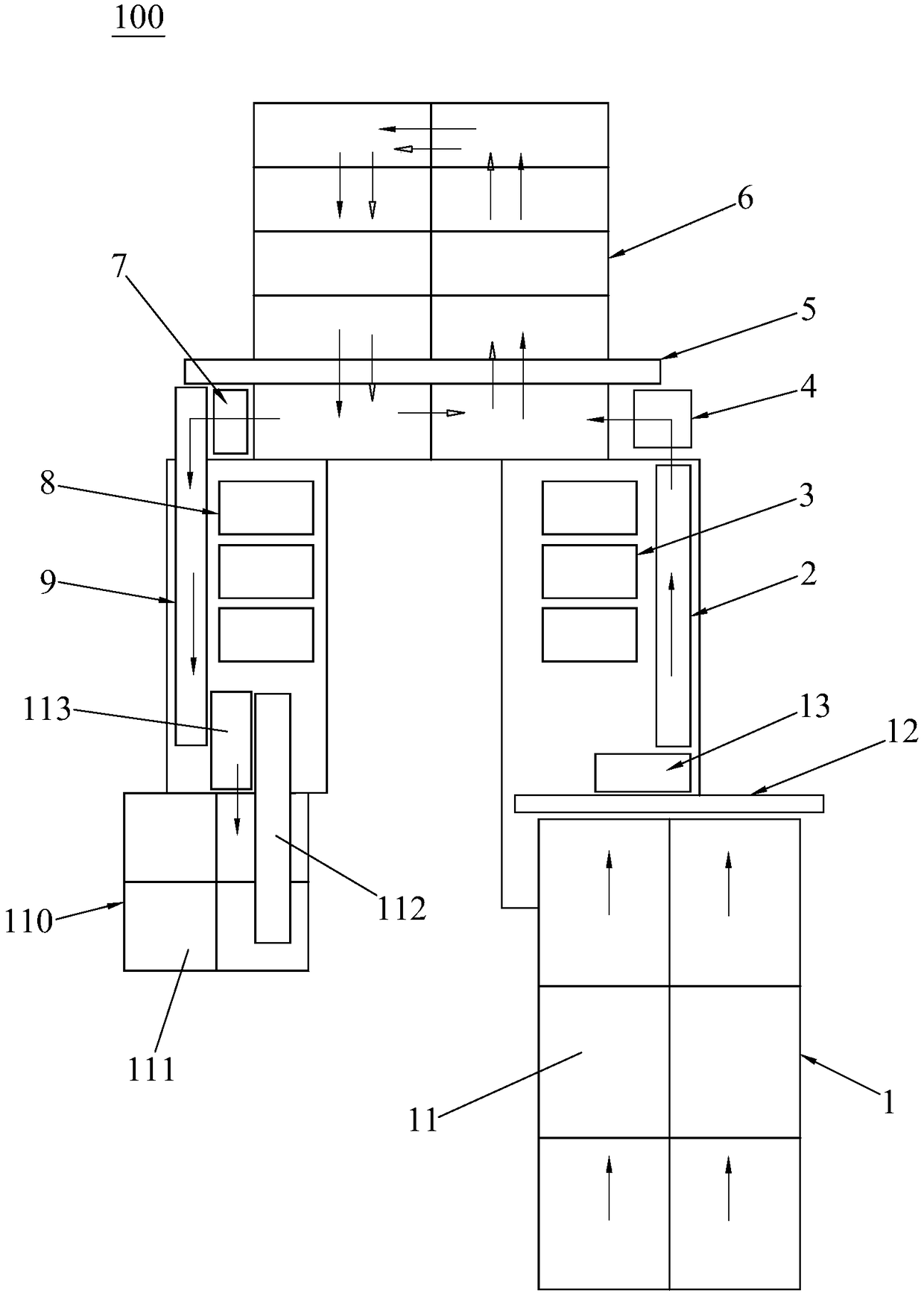

[0019] Such as figure 1 , figure 2 and image 3 As shown, the soft pack lithium battery liquid injection machine 100 with long standing time of the present invention includes a feeding assembly 1, a liquid injection manipulator 2, a vacuum liquid injection device 3, a pretreatment device 4, a static loading and unloading manipulator 5, a static Component 6, post-processing device 7, vacuum packaging device 8, packaging manipulator 9 and blanking component 110; the feeding component 1, the vacuum liquid injection device 3 and the pre-processing device 4 are vertically arranged and the injection The liquid manipulator 2 is arranged between the above-mentioned three; the number of the vacuum liquid injection device 3 in the present invention is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com