Fireproof bus duct

A fire-resistant busway, fire-resistant and flame-retardant technology, applied in cooling busbar devices, fully enclosed busbar devices, etc., can solve problems such as hindering the heat dissipation capacity of busbars, and achieve the effect of improving heat dissipation and fire resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

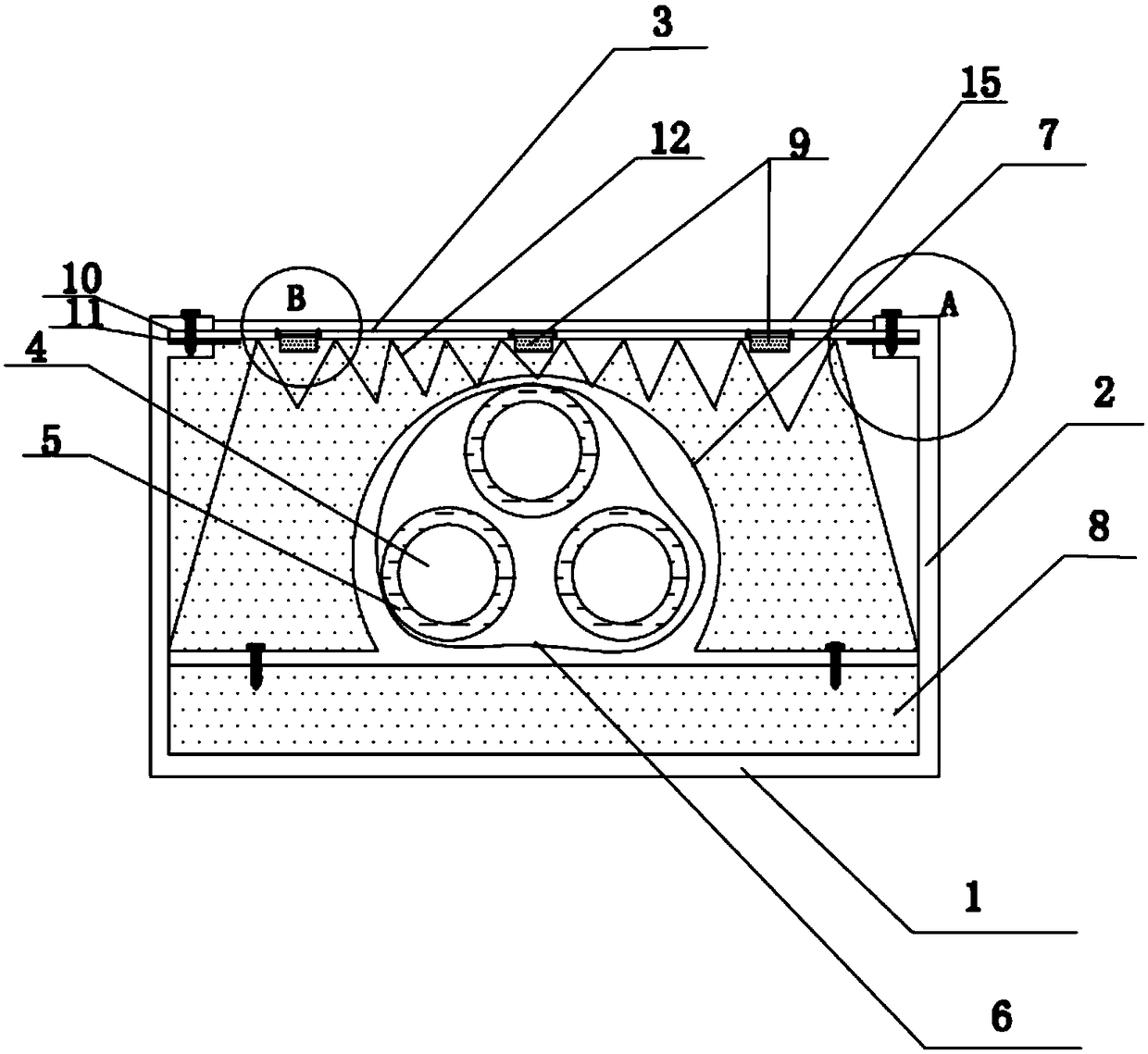

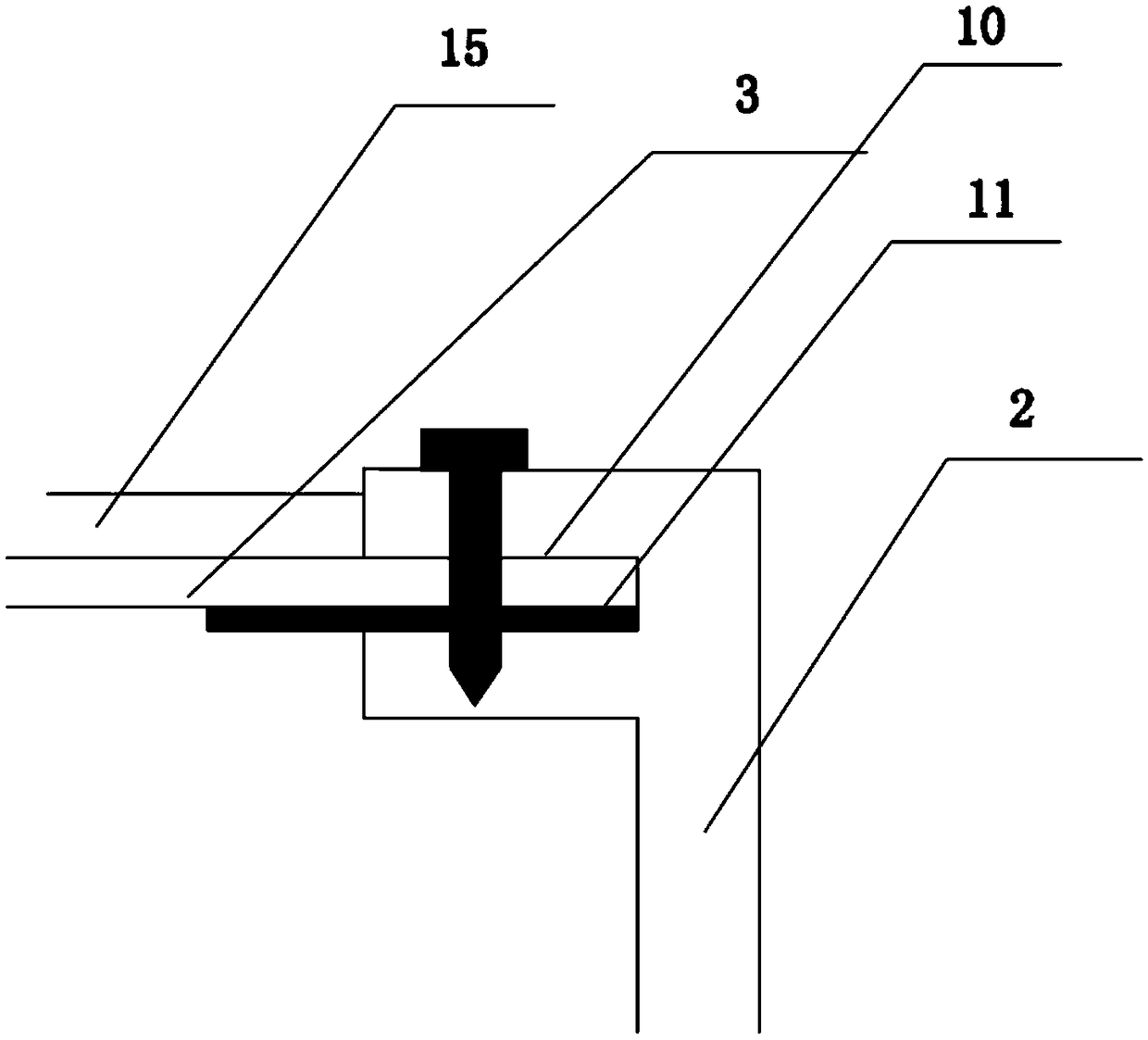

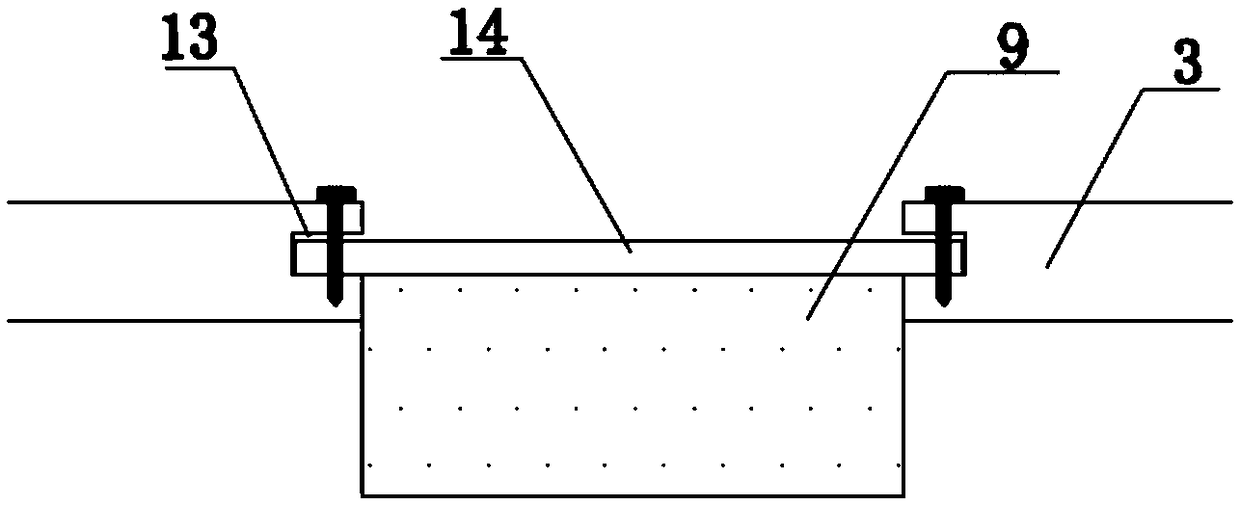

[0021] Such as figure 1 As shown, a refractory bus duct includes a bottom 1, a side 2 and a top cover 3, and the bottom 1, side 2 and top cover 3 form a cavity; the bottom 1, sides 2 and There are multiple wire cores 4 in the cavity surrounded by the top cover 3, the outer layer of each wire core 4 is covered with an insulating layer 5, and the wire cores 4 are wound together by mica tape 6; the outside of the wire core 4 has "Ω ”-shaped sheath 7, with a refractory layer 8 between the sheath 7 and the bottom edge 1; the cavity above the sheath 7, inside the side 2, and below the top cover 3 is filled with fire-resistant and flame-retardant materials; the top cover 3 has several downward recess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com