Processing method of dough sheets during production of functional fine dried noodles and application

A processing method and functional additive technology, applied in the field of noodle product processing, can solve problems such as high cooking loss rate, complex processing technology, and deteriorating noodle quality, so as to improve nutritional value and storage quality, enhance gluten network structure, Effect of reducing nutrient loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

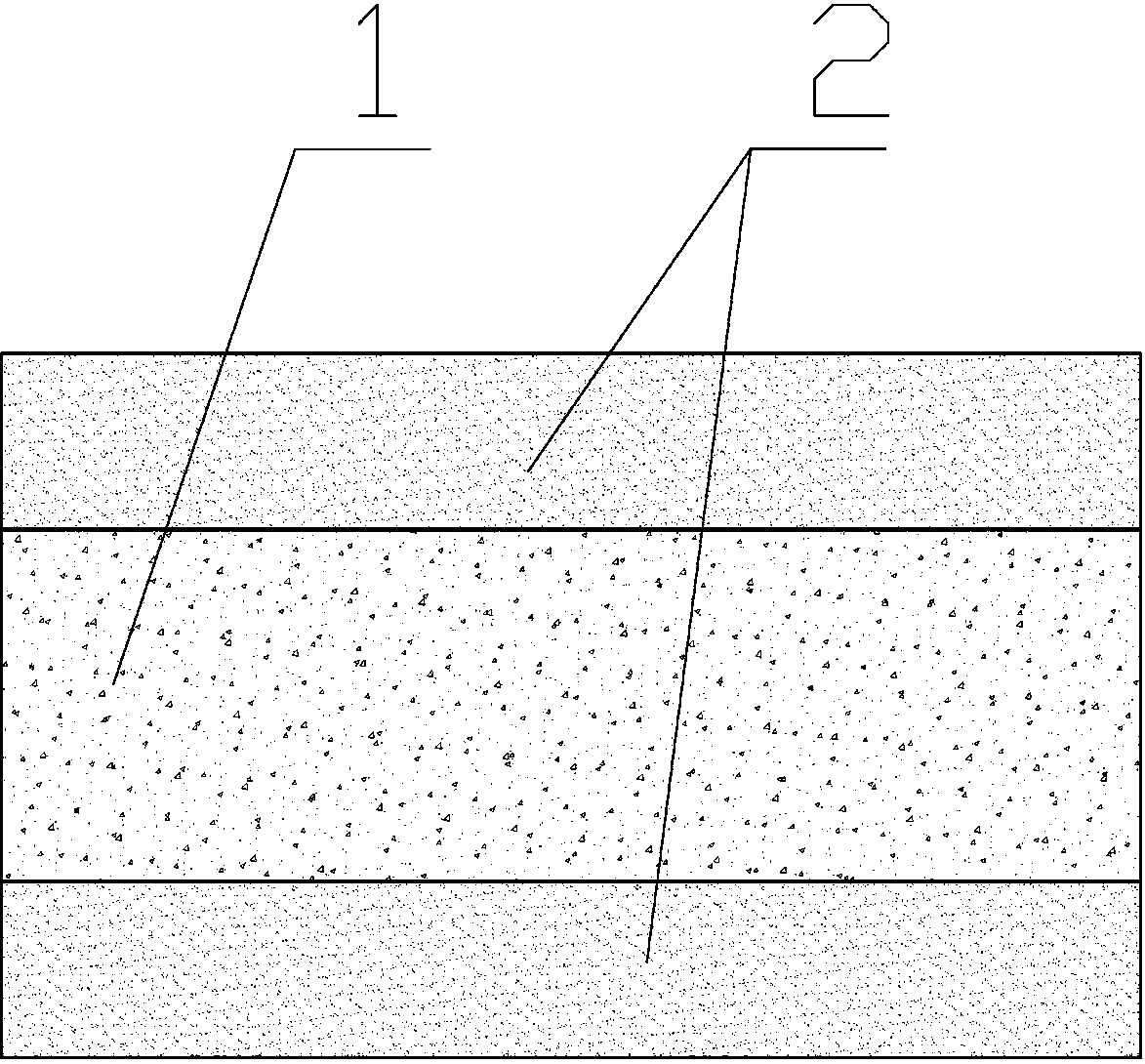

Image

Examples

Embodiment 1

[0046] A processing method of noodles in the production of functional dried noodles, which includes the following steps:

[0047] ⑴Raw material pre-mixing: mix the inner layer powder and outer layer powder uniformly according to the proportion; the inner layer powder is a mixed powder including functional additives and wheat flour, the outer layer flour is wheat flour; the functional additives and the inner layer flour The mass ratio of the wheat flour to the outer flour is 1:1.5-9; the mass ratio of the inner flour to the outer flour is 1:0.5~1;

[0048] In step (1) of the present invention, the ash content of the wheat flour is less than 0.4%, the stabilization time is 5 minutes to 10 minutes, the diameter of starch granules is less than 150 µm, the ash content is less than 0.2%, and the protein content of the active protein is ≥40%; The additives include one or more of gluten or starch or vegetable powder or multivitamins or multi minerals or inulin or oligofructose.

[0049] The...

Embodiment 2

[0077] This embodiment is for the production of noodles for children. The formula is:

[0078]

[0079] Weigh the inner layer powder and outer layer powder raw materials, respectively, pour the inner layer powder and outer layer powder into the mixer and mix them evenly, and the mixing time is 240s.

[0080] The mass ratio of the functional additive in this embodiment to the wheat flour in the inner layer powder and the outer layer powder is 1:3.54; the mass ratio of the inner layer powder to the outer layer powder is 1:1; the added amount of fructooligosaccharide is 20% .

[0081] In this embodiment, the mixed inner layer powder and outer layer powder are thoroughly sieved through a cleaning sieve, and then put into a vacuum kneading machine, water is added, and the water temperature is 22° C., and the kneading time is 18 minutes. The requirements for the kneading process are as follows: the blank is in the form of snowflake-shaped loose particles, with moderate dryness and wetnes...

Embodiment 3

[0090] This embodiment is for the production of noodles for children. The formula is:

[0091]

[0092] Weigh the inner layer powder and outer layer powder raw materials, and pour the inner layer powder and outer layer powder into the mixer respectively, and mix them evenly. The mixing time is 300s.

[0093] The mass ratio of the functional additive in this embodiment to the wheat flour in the inner layer powder and the outer layer powder is 1:1.93; the mass ratio of the inner layer powder to the outer layer powder is 1:1; the added amount of oligofructose is 30% .

[0094] In this embodiment, the mixed inner layer powder and outer layer powder are thoroughly sieved through a cleaning sieve, and then put into a vacuum mixing machine, water is added, and the water temperature is 25° C., and the mixing time is 25 minutes. The requirements for the kneading process are as follows: the blank is in the form of snowflake-shaped loose particles, moderately wet and dry, uniform in color, fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap