Self-coated non- vascular orifice insertion tube

A non-vascular, tube-inserting technology, applied in the field of rapid secondary coating devices, can solve the problems of long operation time, loss of drug properties, uneven thickness, etc., and achieve the effect of uniform coating and stable drug dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

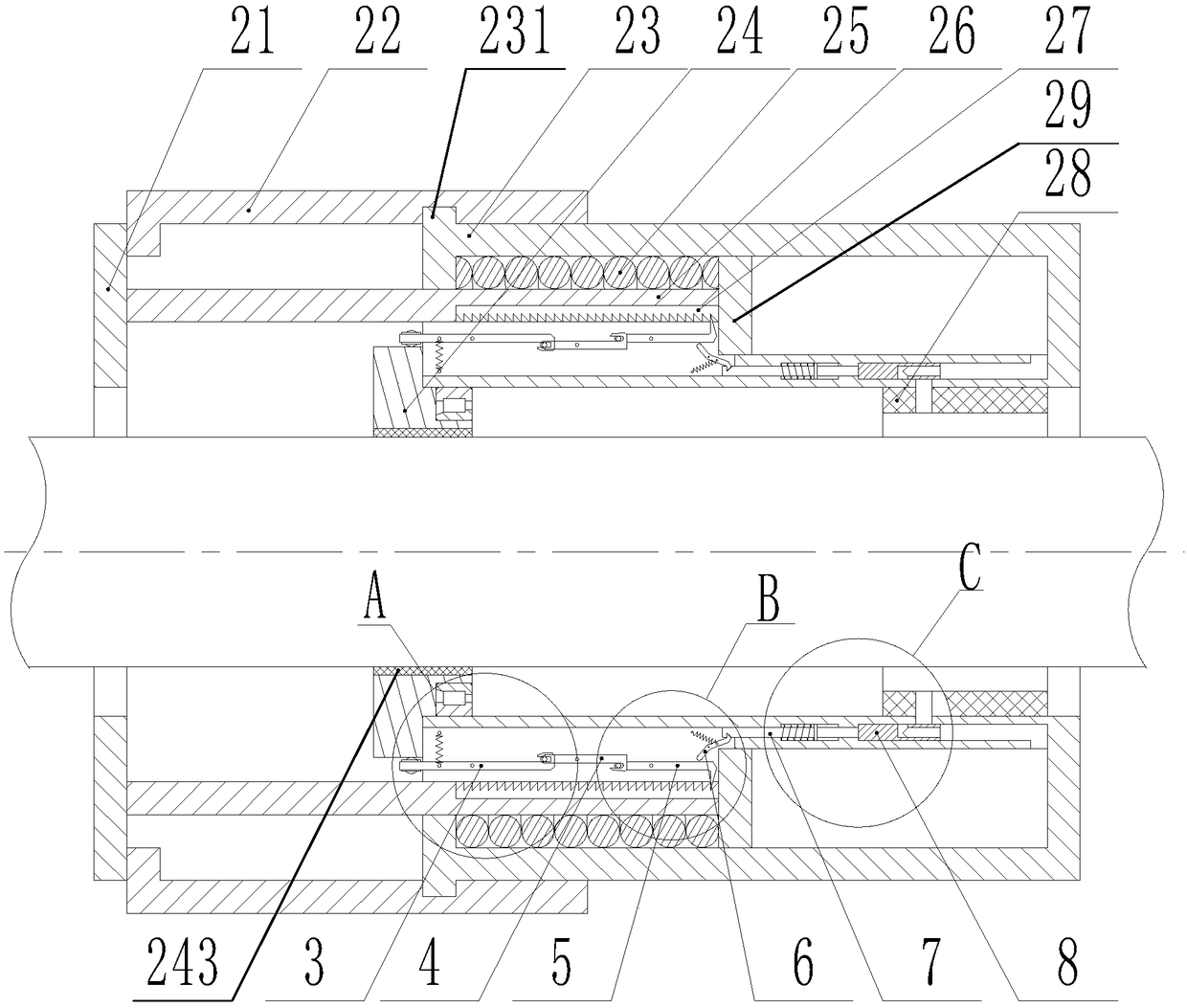

Method used

Image

Examples

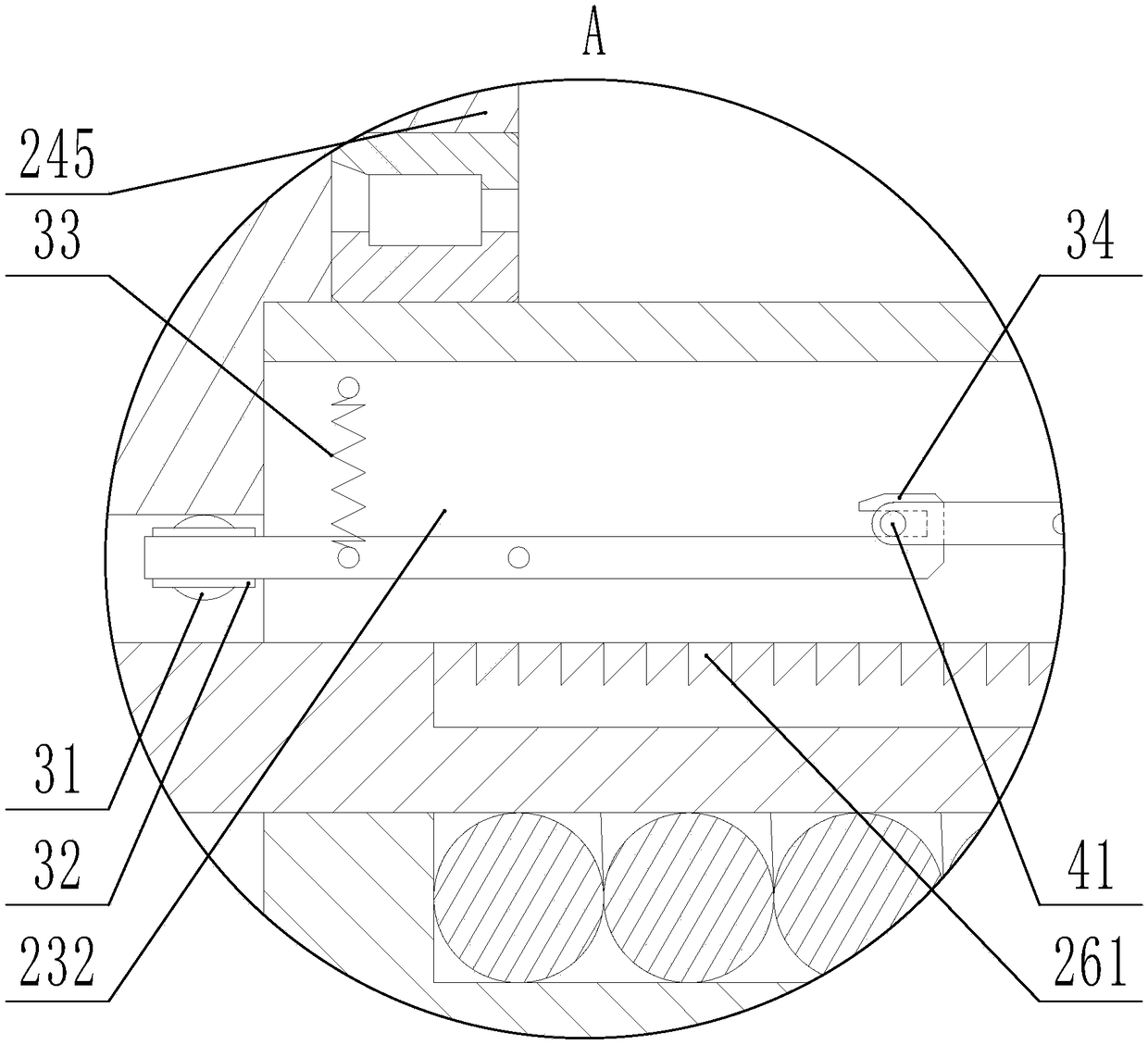

Embodiment 1

[0043] The outer cylinder 22 and the inner cylinder 23 described in Embodiment 1 are not fixed by a limiting device, so that the outer cylinder 22 is easily rotated relative to the inner cylinder 23 during transportation, so that the outer cylinder The arc-shaped stopper 221 at the left end of 22 rotates to the arc-shaped notch of the annular top plate 21, so that the ratchet 52 is subjected to excessive force, thereby causing damage. However, in embodiment 2, a limiting device is added to fix the outer cylinder 22 and the inner cylinder 23, as Figure 9 , 10 As shown, the inner wall of the right end of the outer cylinder 22 is provided with two symmetrically distributed notches 226, and a limit rod 222 is installed in the notch 226 of the outer cylinder, and the middle position of the limit rod 222 is Hinged with the side wall of the notch 226 of the outer cylinder 22, the outer wall of the inner cylinder 23 is provided with two positioning holes corresponding to the notch 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com