Device for glass sleeve inside polishing

A glass sleeve and polishing cylinder technology, which is applied to grinding/polishing equipment, surface-polished machine tools, and parts of grinding machine tools, etc., can solve the problems of uneven spraying of polishing liquid, affecting visual sense, uneven scratches, etc. , to achieve the polishing effect and the effect of high efficiency, large polishing area and high practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

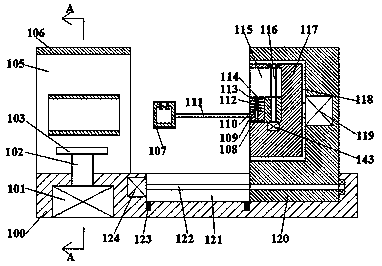

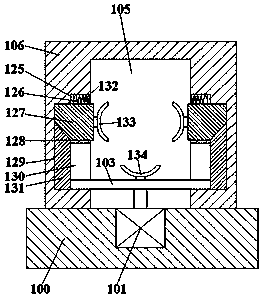

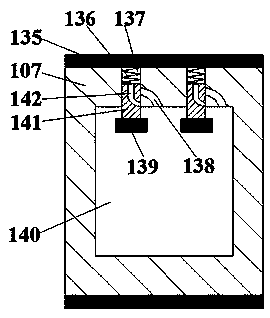

[0015] Such as figure 1 , figure 2 and image 3 As shown, the internal polishing of the glass sleeve of the present invention includes a base 100 and a firmware body 106 arranged on the top end surface of the base 100, and a polishing chamber 105 is provided through the left and right sides of the firmware body 106, and the polishing chamber 105 The front and rear inner walls are communicated with a first symmetrical guide chute 128, and the front and rear inner walls of the polishing chamber 105 are communicated with a symmetrical second guide chute 130, and the second guide chute 130 is far away from the polishing chamber. The inner wall of the end 105 communicates with a third guide chute 129, and the top of the third guide chute 129 communicates with the first guide chute 128, and the first guide chute 128 is slidably connected with a first guide chute. Slider 127, described first guide slider 127 is provided with side arc-shaped gripper 133 near described polishing cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com