Full-automatic optical fiber cutting machine

An optical fiber cutting machine, fully automated technology, applied in metal processing and other directions, can solve the problems of inability to effectively meet the simultaneous cutting of multiple optical fibers, operator injury, and low cutting precision, so as to improve cutting efficiency and The effect of cutting precision, reducing labor cost and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

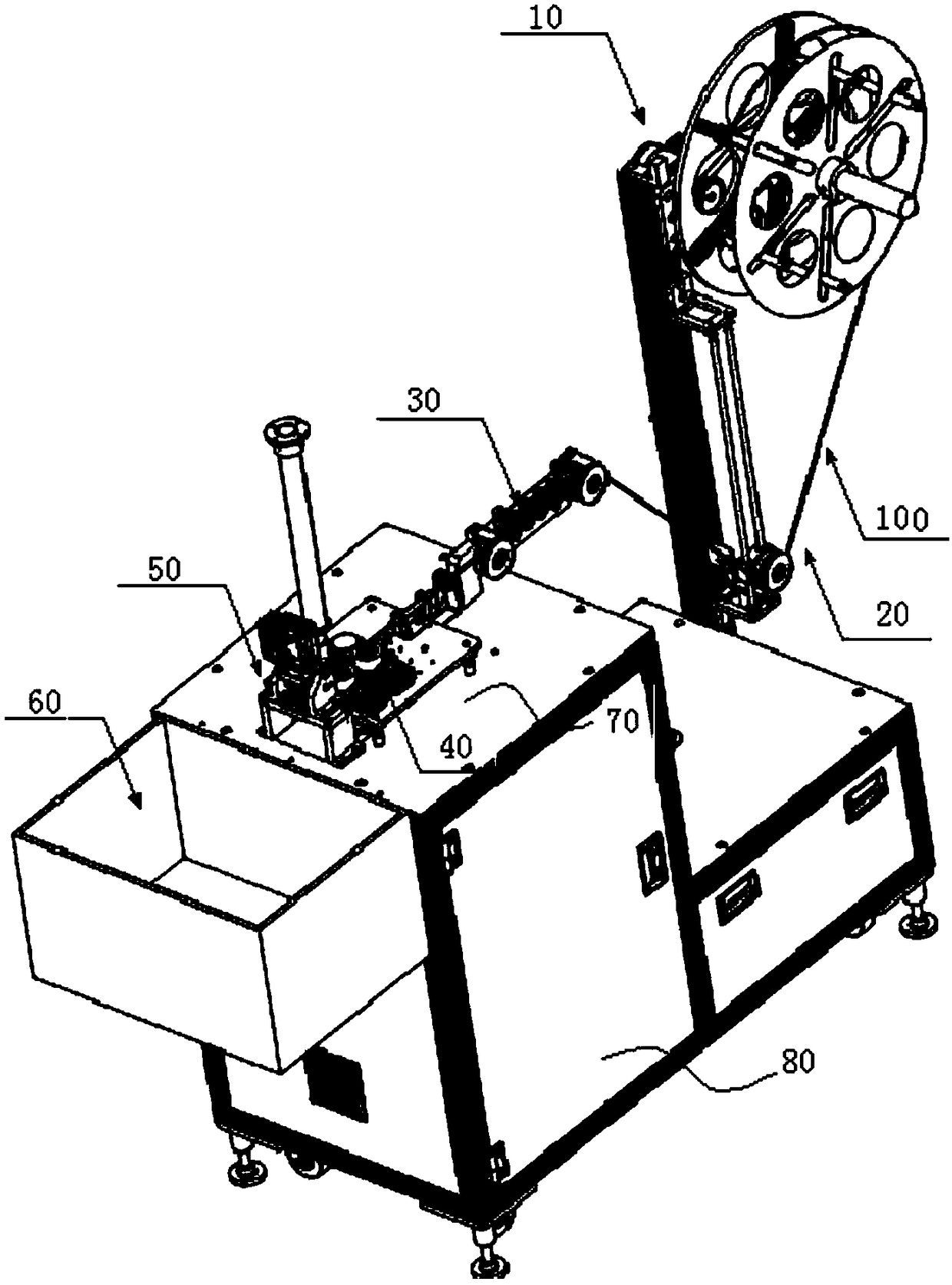

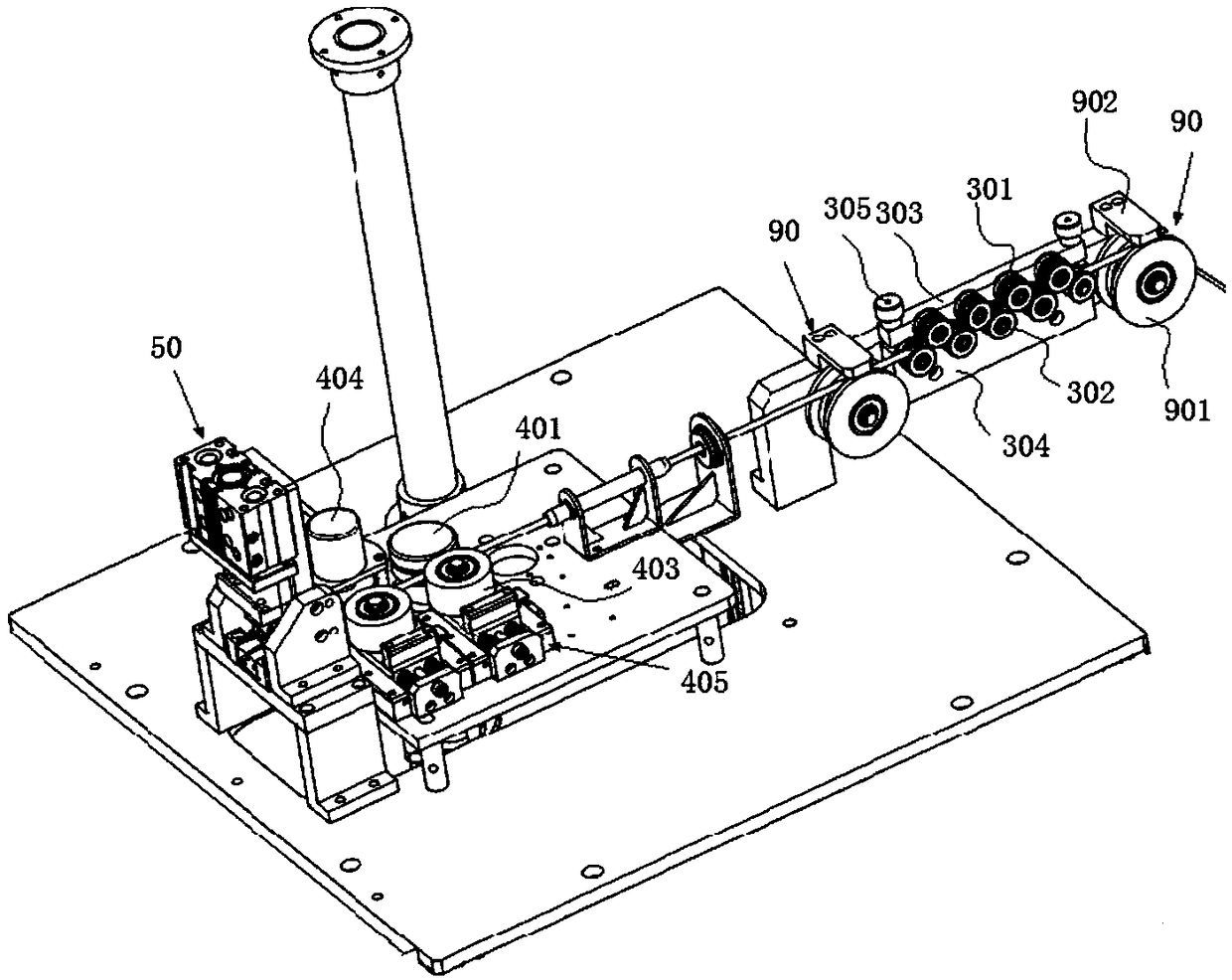

[0043] Embodiment: a kind of fully automatic optical fiber cutting machine, as Figure 1 to Figure 11 As shown, it includes a feeding device 10, a tensioning device 20, a straightening device 30, a traction device 40, a cutting device 50 and a receiving box 60 arranged in sequence according to the transmission direction of the optical fiber 100. The tightening device, the straightening device, the pulling device and the cutting device are all installed on the machine table 70, and the optical fiber is wound around the feeding device and bypasses the tensioning device and passes through the straightening device in turn. straight device and said traction device, then cut off by said cutting device and fall into the collection box;

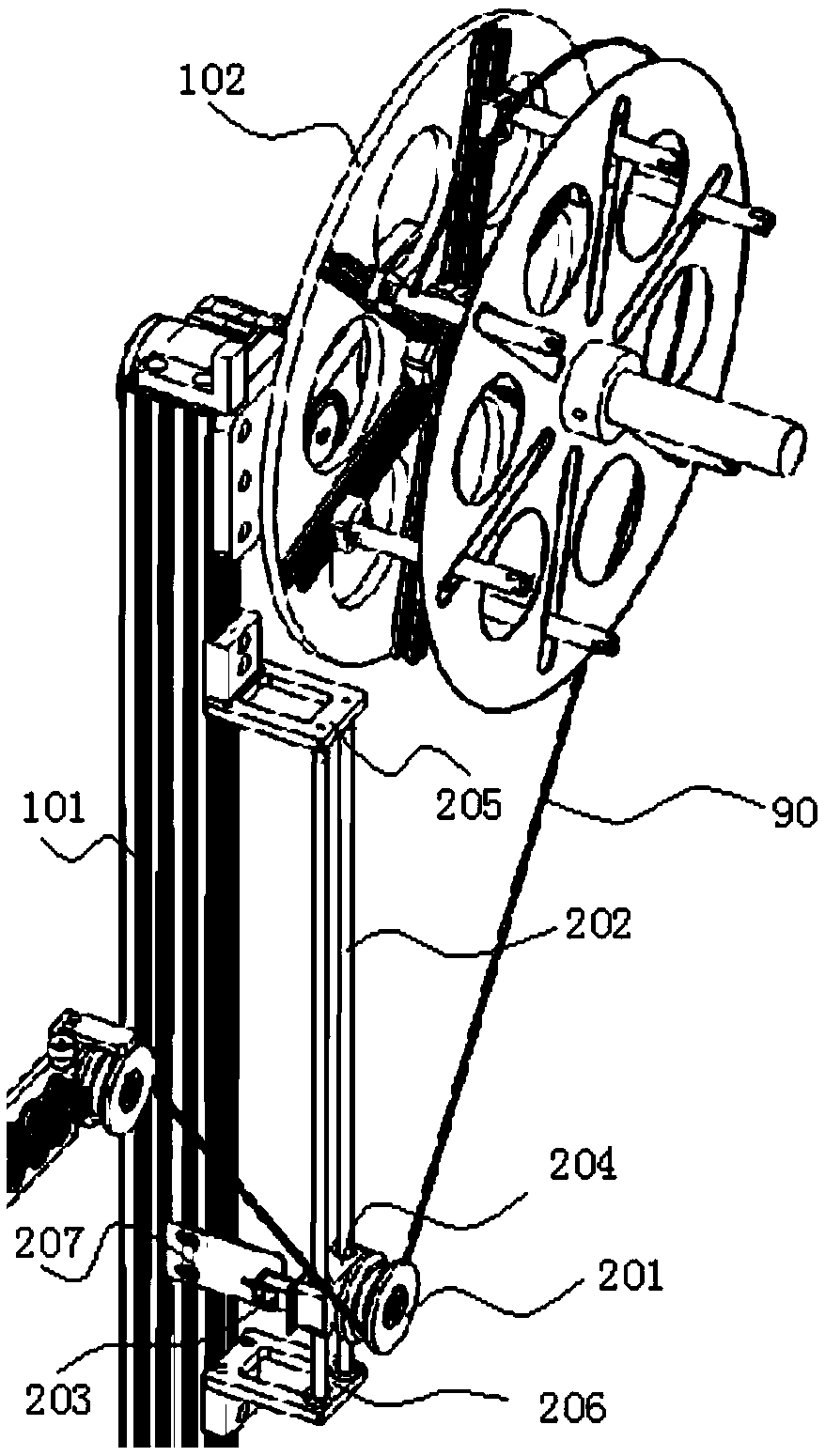

[0044] Such as image 3 and Figure 4 As shown, the discharge device 10 includes a discharge rack 101, a discharge tray 102 and a first drive mechanism 103 that drives the rotation of the discharge tray, the discharge rack is installed on the machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com