Hybrid power composite unmanned helicopter

An unmanned helicopter and hybrid power technology, applied in the field of unmanned aerial vehicles, can solve problems such as complex power structure, accident-prone, and helicopter out-of-control, and achieve the effect of simplifying the structure of the aircraft, avoiding complete loss of control, and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

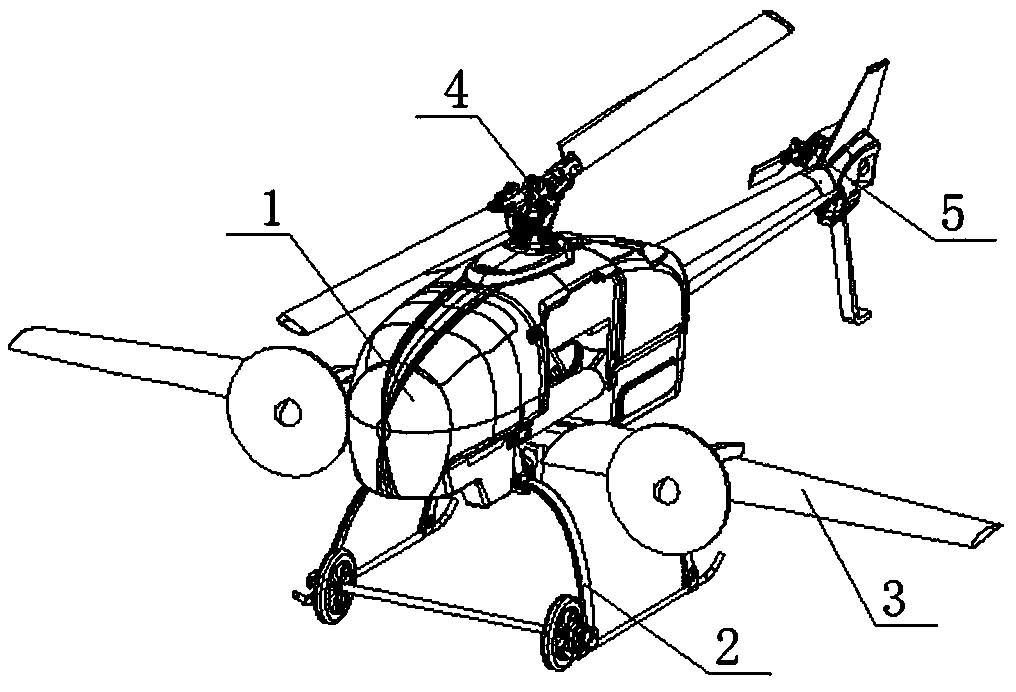

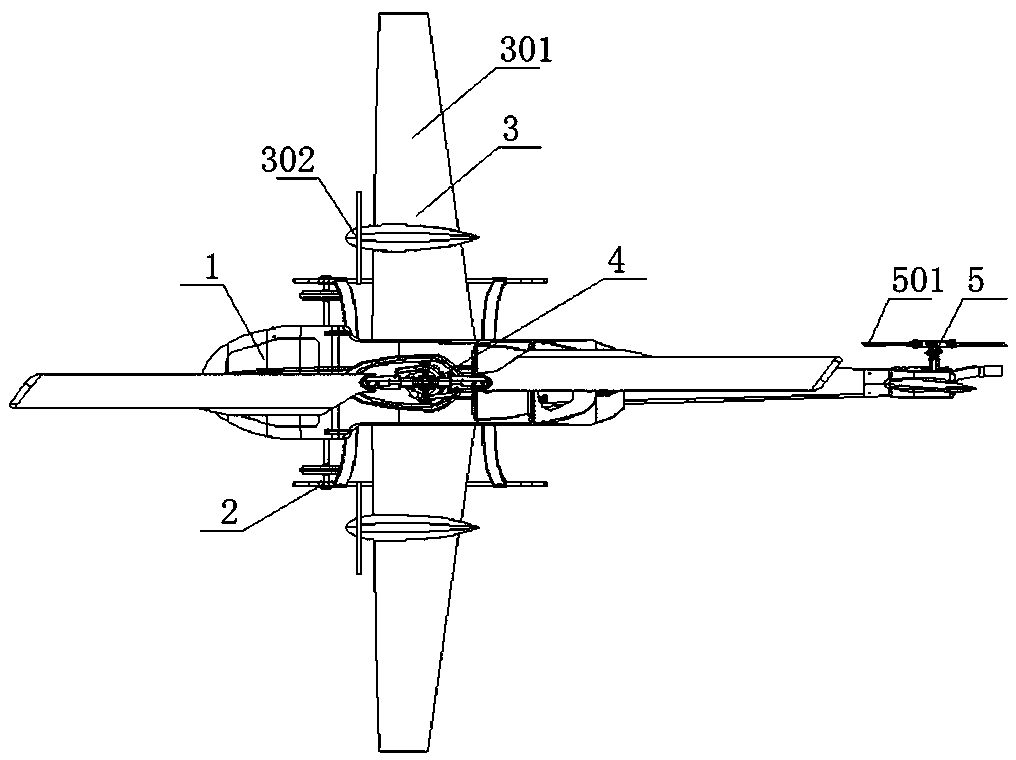

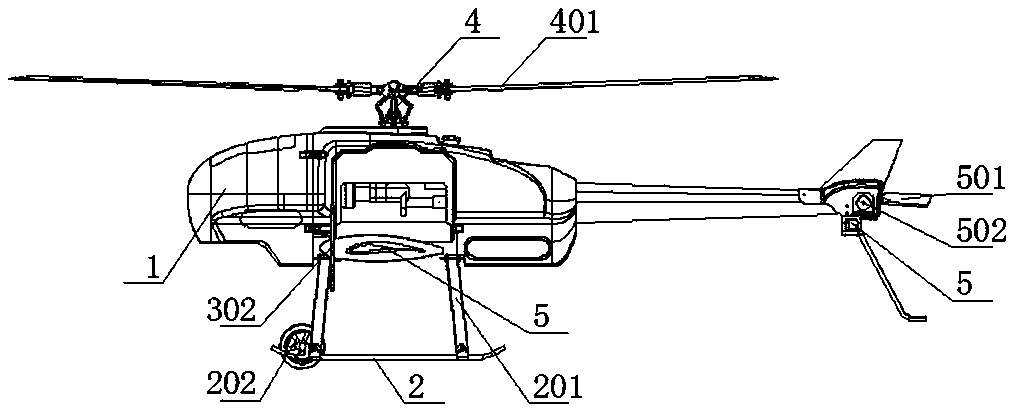

[0037] Such as Figure 1~Figure 11 As shown, a hybrid unmanned helicopter includes a fuselage 1, and also includes a landing gear assembly 2 fixed on the lower part of the fuselage 1, a short wing assembly 3 arranged symmetrically on both sides of the fuselage 1, and a wing assembly 3 in the middle of the fuselage 1. The main propeller assembly 4 and the tail rotor assembly 5 at the rear of the fuselage 1;

[0038] The landing gear assembly 2 includes a frame body 201 and a detachable road wheel assembly 202 connected with the bottom bolts of the frame body 201; to ensure the safety of the fuselage 1, before take-off and after landing, the detachable road wheel assembly 202 is used to make the landing gear assembly 202 The landing gear assembly 2 drives the fuselage 1 to slide forward, which increases the convenience of the unm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com