One-station dual-unit stereoscopic garbage disposal station achieving winding and lifting

A technology of garbage disposal station and hoist, which is applied in the directions of garbage conveying, garbage collection, loading/unloading, etc. It can solve the problems of inability to meet the requirements of diversity, trouble and time-consuming, pollution, etc., so as to save exchange time, save land area, Simple and fast process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

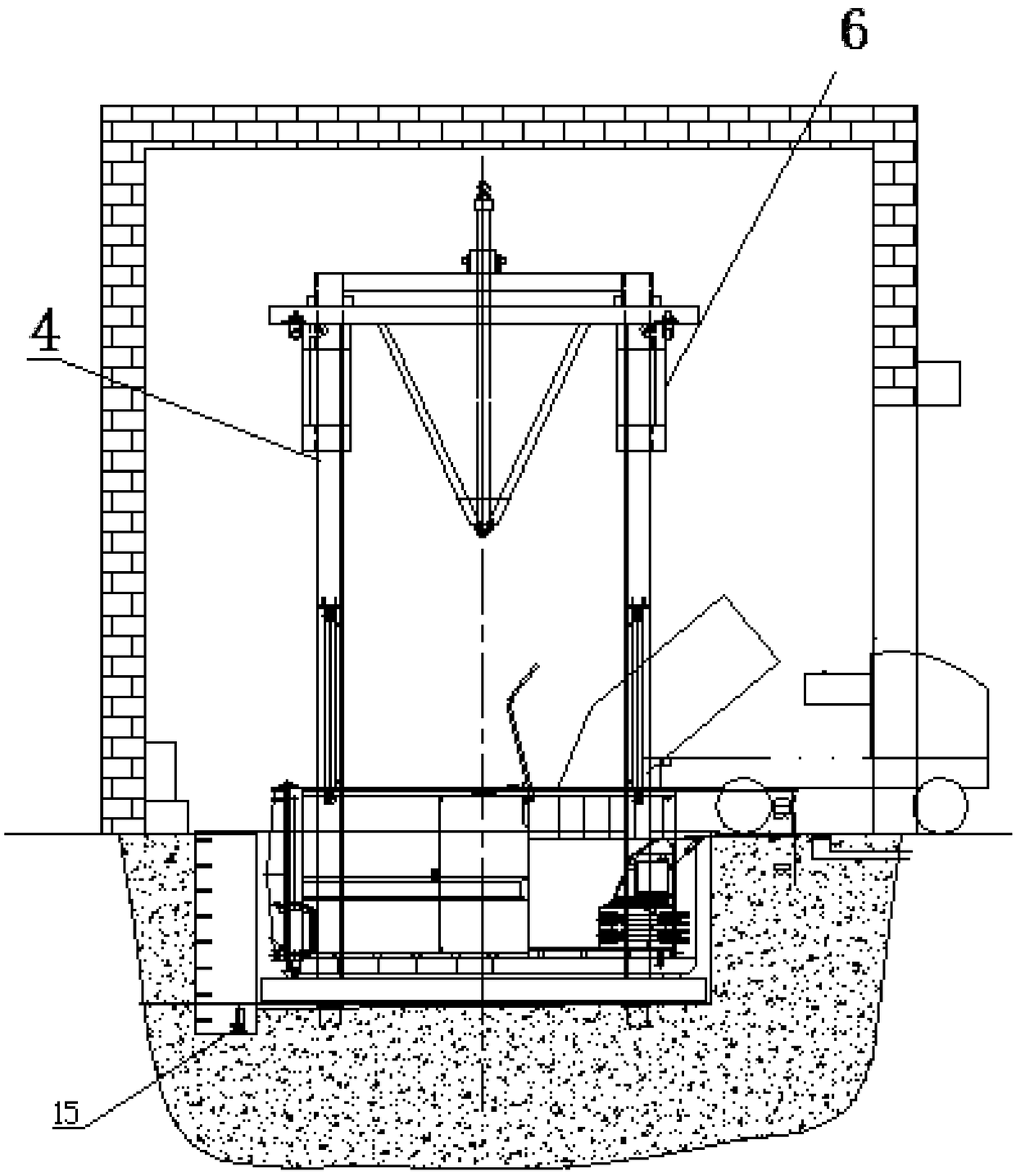

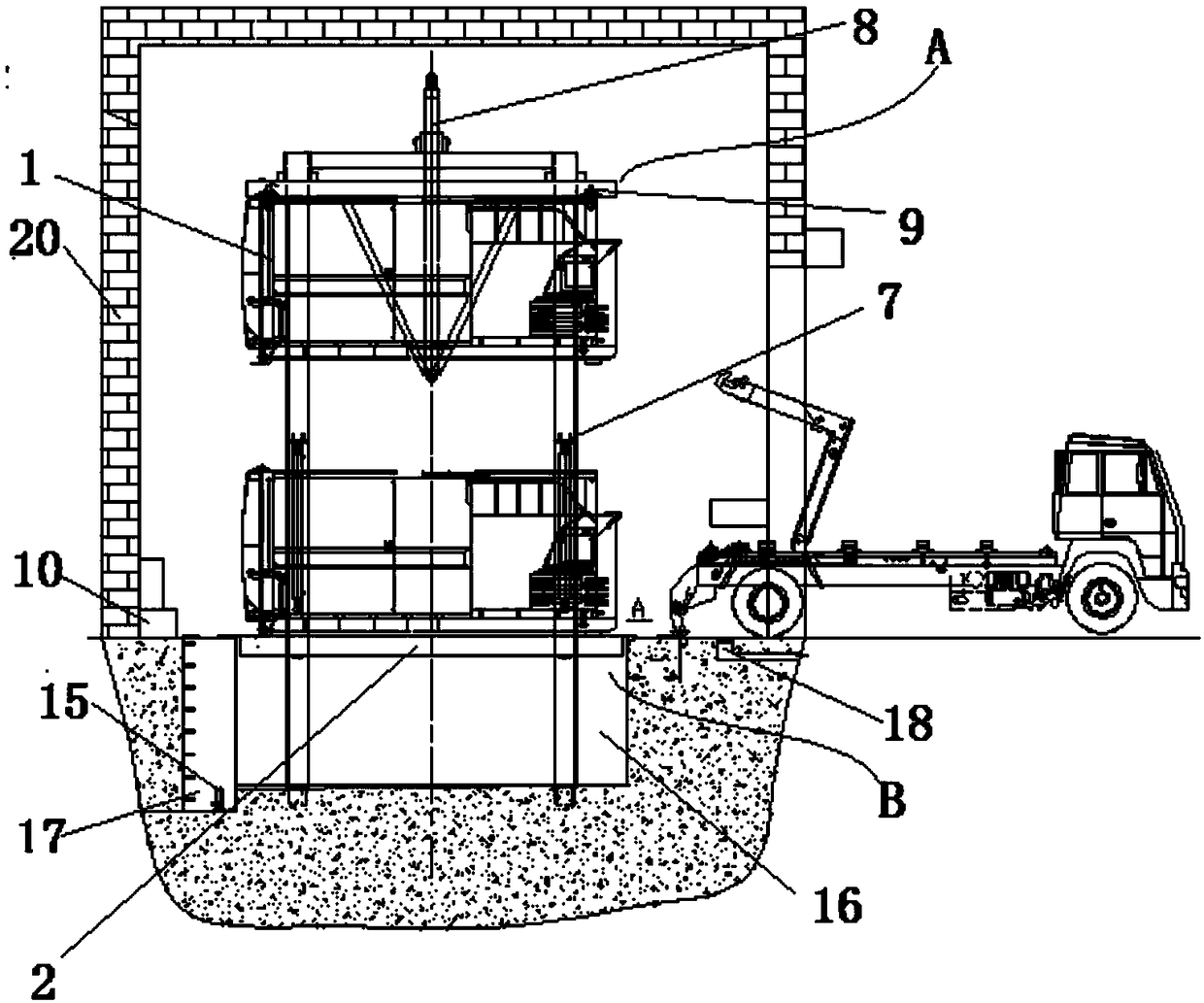

Image

Examples

Embodiment 2

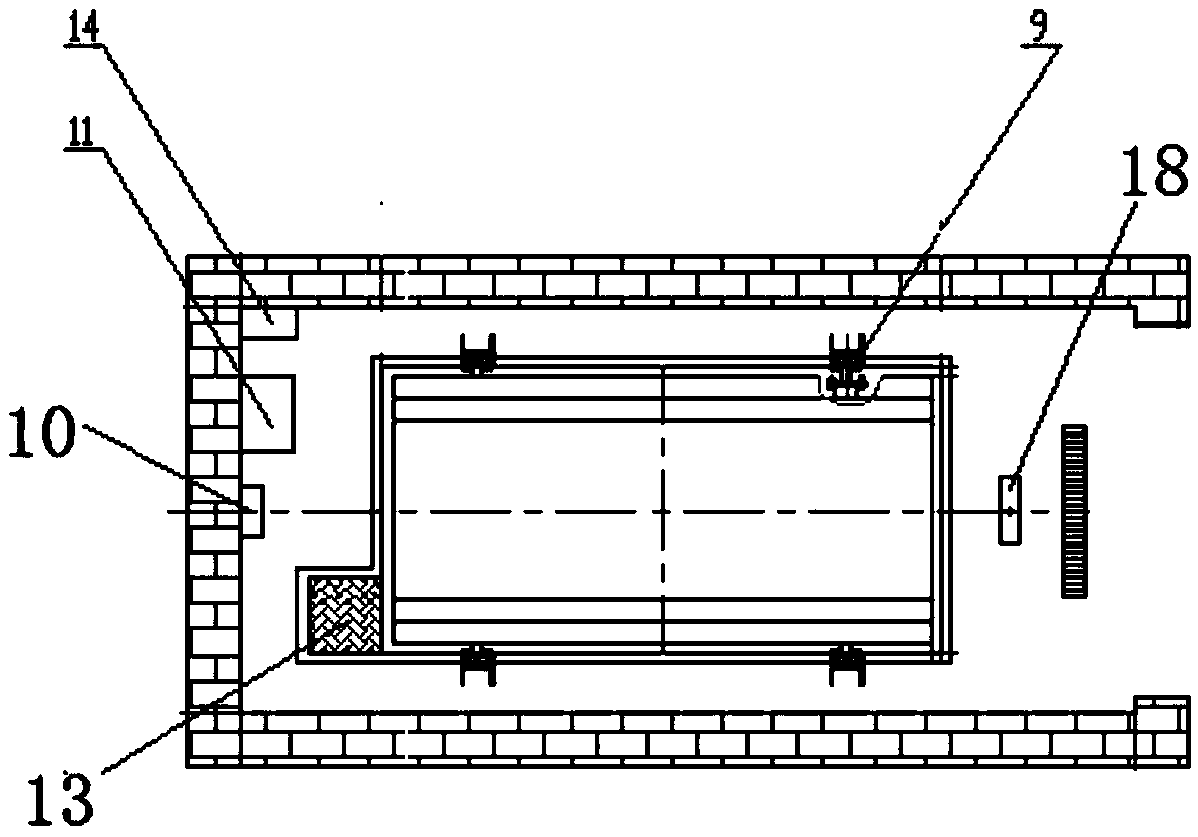

[0052] like Figure 6-7 As shown, the dustbin is preferably a compressed dustbin. In order to facilitate the discharge of sewage in the dustbin, a first groove 2 is provided along the width direction of the compressed dustbin at the end of the inner bottom of the dustbin, and the first groove 2 communicates with the The water pipe 5, the first groove 2 is connected with the second groove 12 arranged along the length direction of the garbage bin, the pit body 16 is provided with a water inlet 21 matched with the water outlet pipe 5, and the water inlet 21 is connected to the pit 17 through the water pipe 22 .

Embodiment 3

[0054] like Figure 8 and 9 As shown, in order to prevent the rubbish from falling into the dustbin and the pit body 16, and the rubbish floats out from the entrance of the dustbin during the way of transporting the waste, the dustbin is improved as follows: a cover 27 is installed at the entrance of the dustbin 1, and the middle part of the cover 27 A lever 28 is pivotally connected, and the middle part of the lever 28 is pivotally connected to the side of the dustbin 1 through a rotating shaft 29. One end of the lever 28 is pivotally connected to the cover 27, and the other end is pivotally connected to a telescopic structure 30. The telescopic structure is a cylinder or an oil cylinder, and the telescopic structure is pivotally connected to the On the side wall of dustbin 1. The distance from the telescopic structure 30 to the rotating shaft 29 is smaller than the distance from the joint of the cover 27 and the lever 28 to the rotating shaft 29 . The cover 27 is fixed wit...

Embodiment 4

[0057] When the existing compression dustbin compresses the garbage, there is usually a gap between the pressing plate and the top of the dustbin, so that the air is discharged during compression. However, when the garbage is compressed, the lower part of the garbage is stressed, which causes the garbage to turn up. When the garbage is compressed, a large part of the compression force is concentrated on the top of the garbage bin, and the outer wall of the garbage bin is thinner except for the rear cover. The top wall of the dustbin is easily deformed by compression, which reduces the service life.

[0058] For this reason Figure 10 and 11 As shown, the compression dustbin is divided into a front casing 32 and a rear casing 33, the front casing is rectangular, and the rear casing is wedge-shaped. The inlet and platen of the dustbin are in the front box 32 . In this way, the pressing plate runs back and forth in the front box body 32, and the garbage in the rear box body 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com