Heating device for gas filtration system

A filter system and heating device technology, applied in biochemical cleaning devices, enzymology/microbiology devices, specific-purpose bioreactors/fermenters, etc., can solve problems such as low efficiency and large heat loss, and prevent condensation Water, ensure the use function, broaden the effect of the use environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

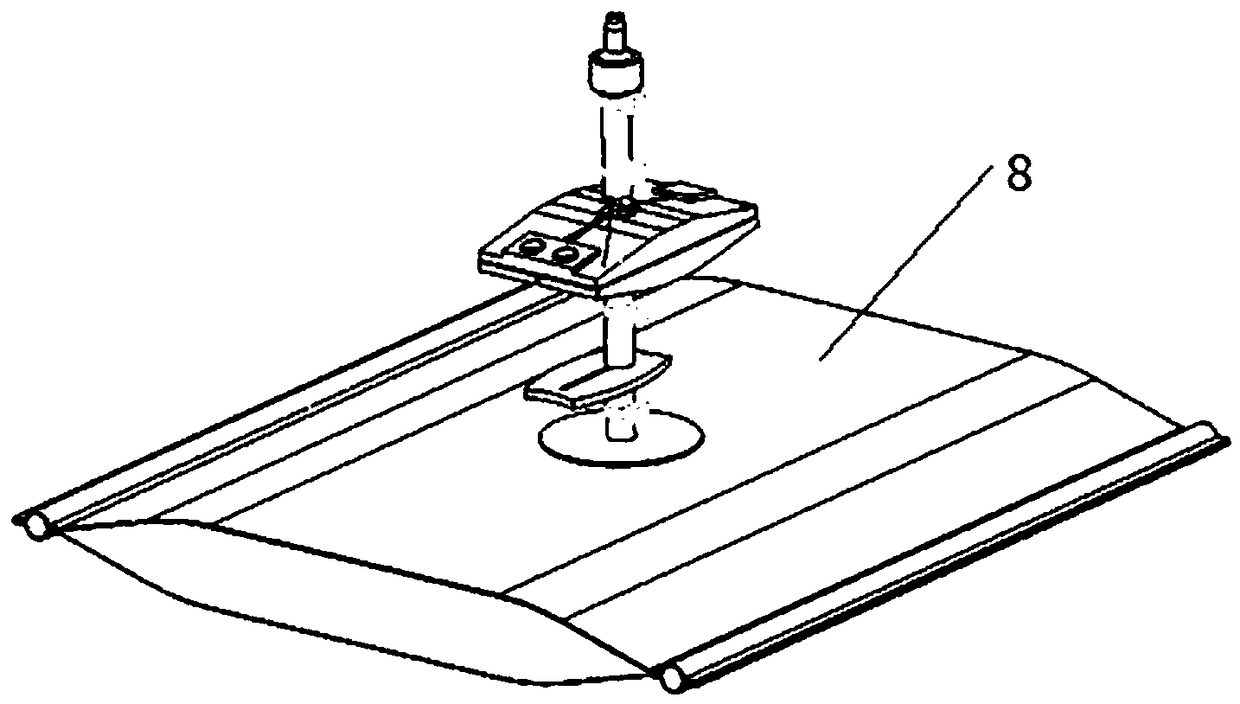

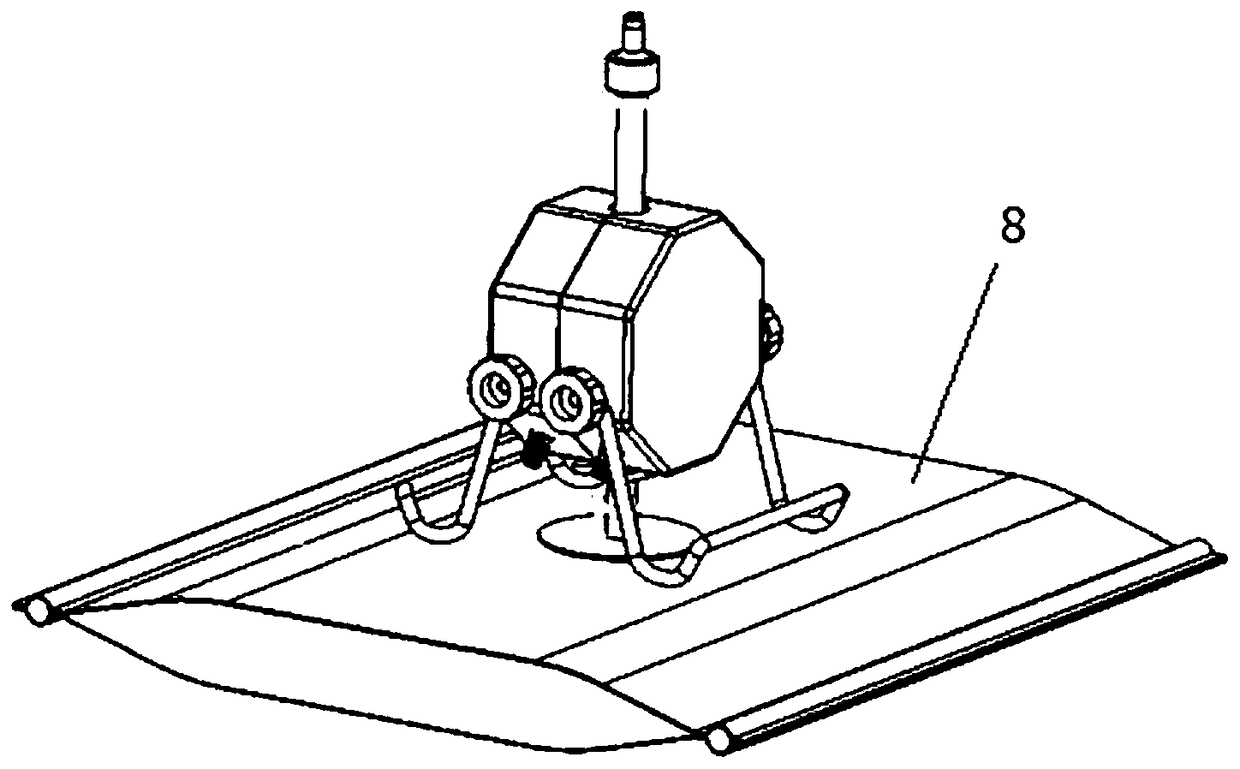

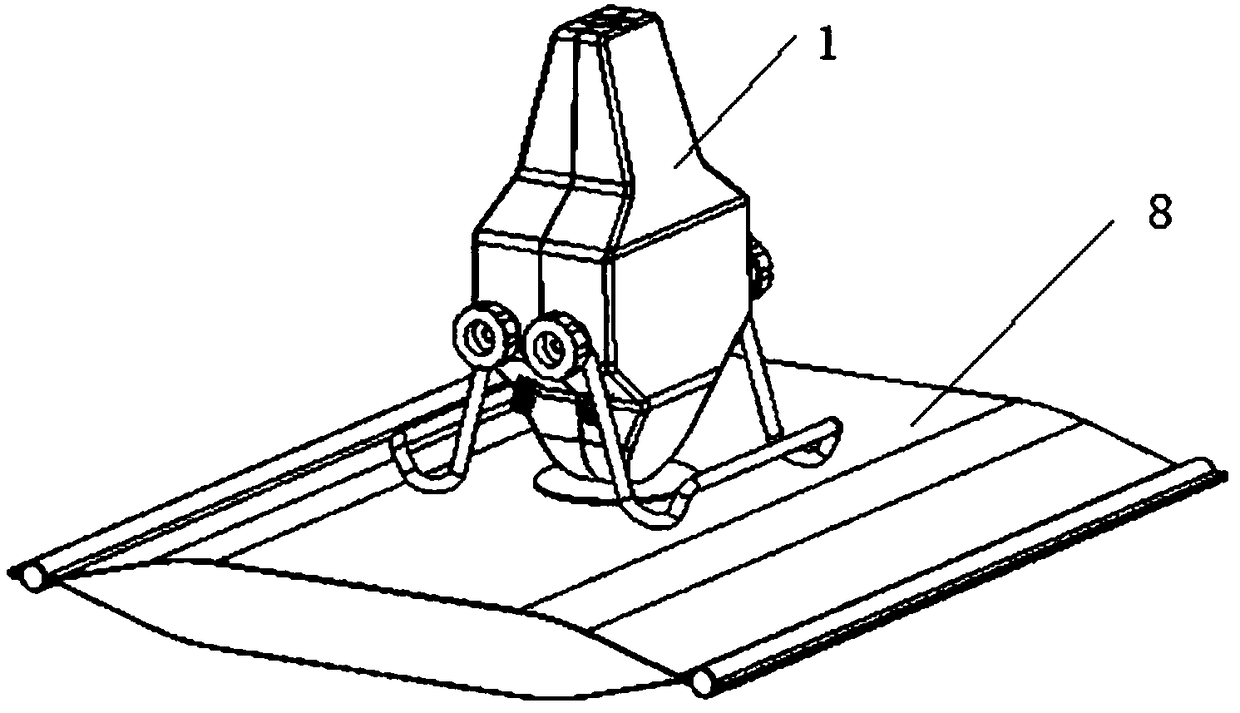

[0026] Such as Figure 3-7 The shown heating device for the gas filtration system includes a casing 1 for wrapping the gas filtration system 3, a heating plate 2 arranged in the casing 1, and a bracket 4 arranged on the casing 1 for adjusting its height The upper end and the lower end of the housing 1 are provided with a through hole 10 through which the pipeline of the gas filtration system 3 passes. When the gas filtration system 3 is placed in the housing 1, the housing 1 is in a fully closed state; the housing 1 includes The abutting and detachable left housing part 1.1 and right housing part 1.2; the bracket 4 is connected to the housing 1 through the rotating mechanism 5; Such as Figure 8 The shown gas filter system 3 includes a gas filter 3.1, an air inlet pipe 3.2 located at one end of the gas filter 3.1, an air outlet pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com