Automobile safety air bag hinge net cloth of warp knitting structure

A technology of automobile safety and airbags, which is applied in warp knitting, motor vehicles, transportation and packaging, etc., and can solve problems such as easy hooking, inconvenient operation, and loose structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

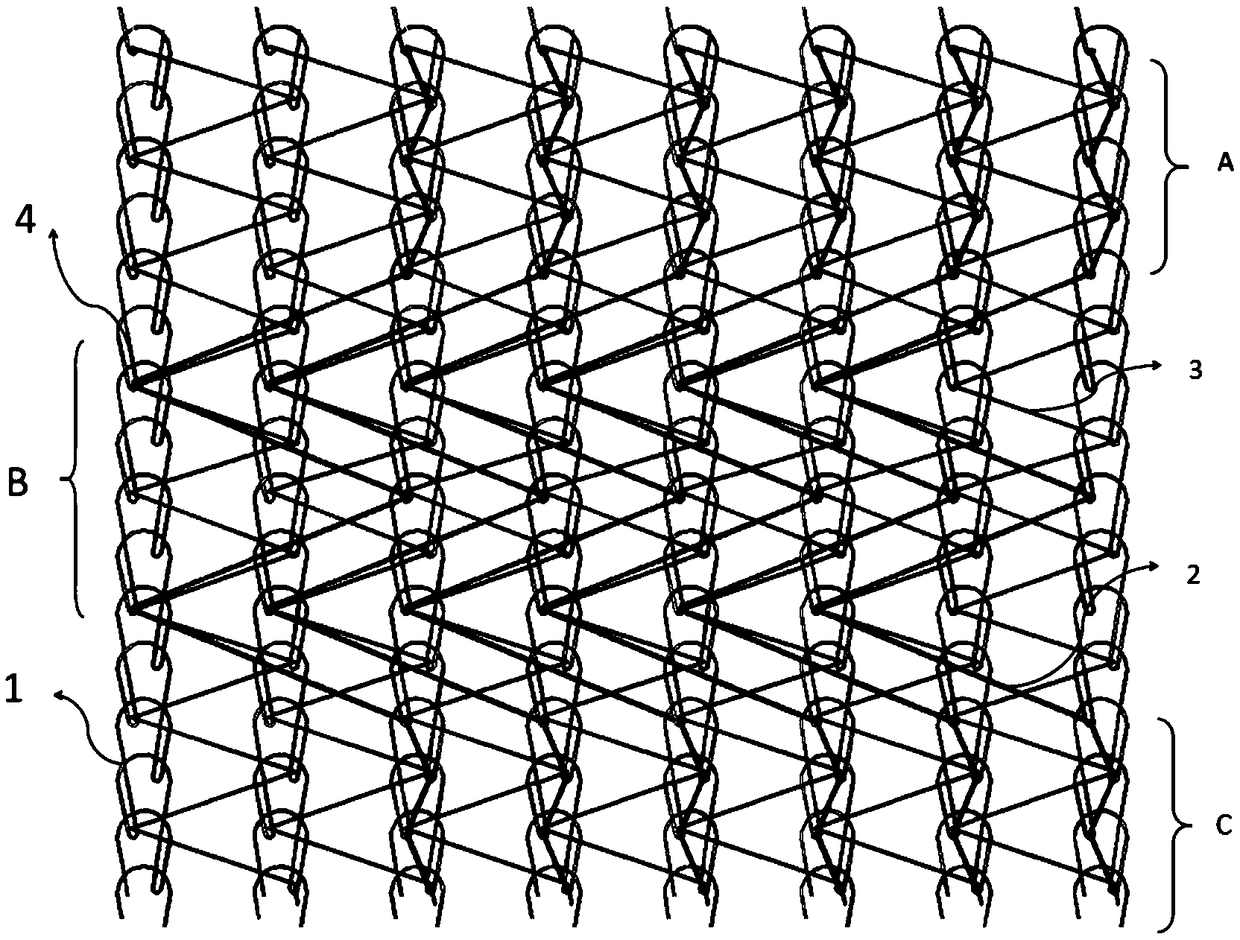

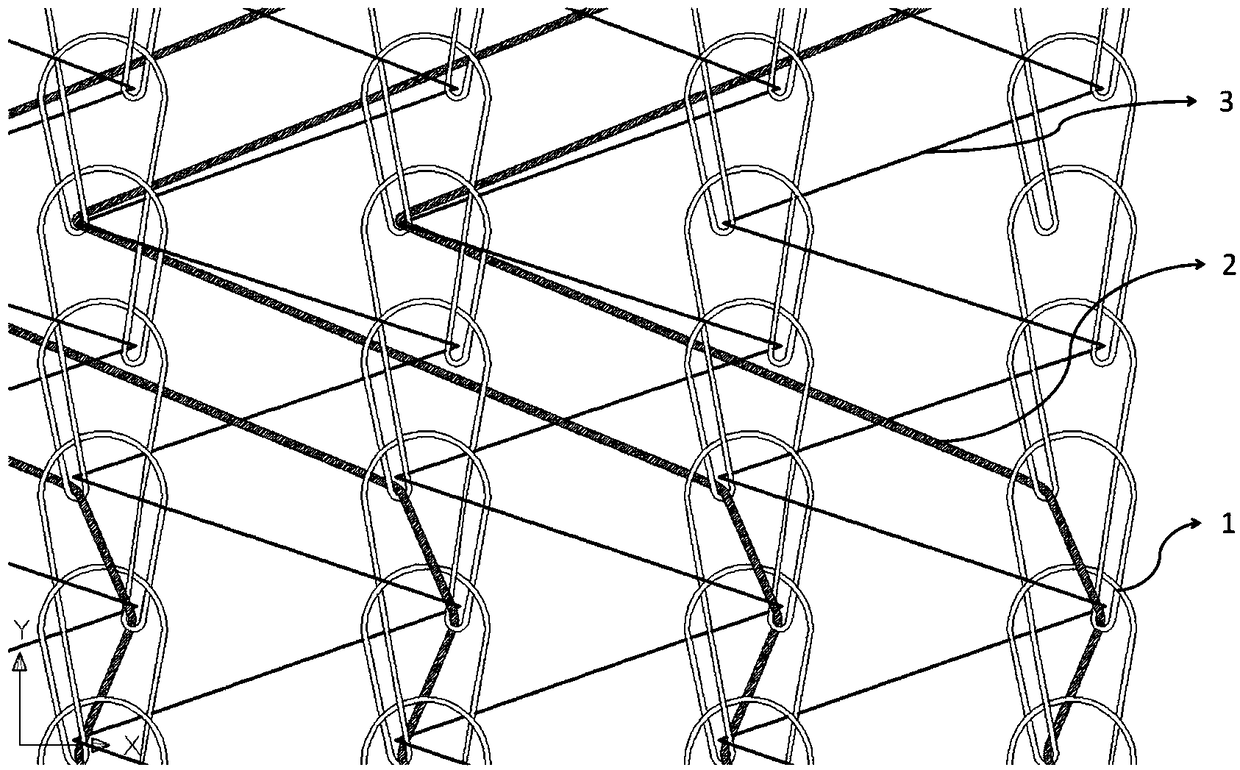

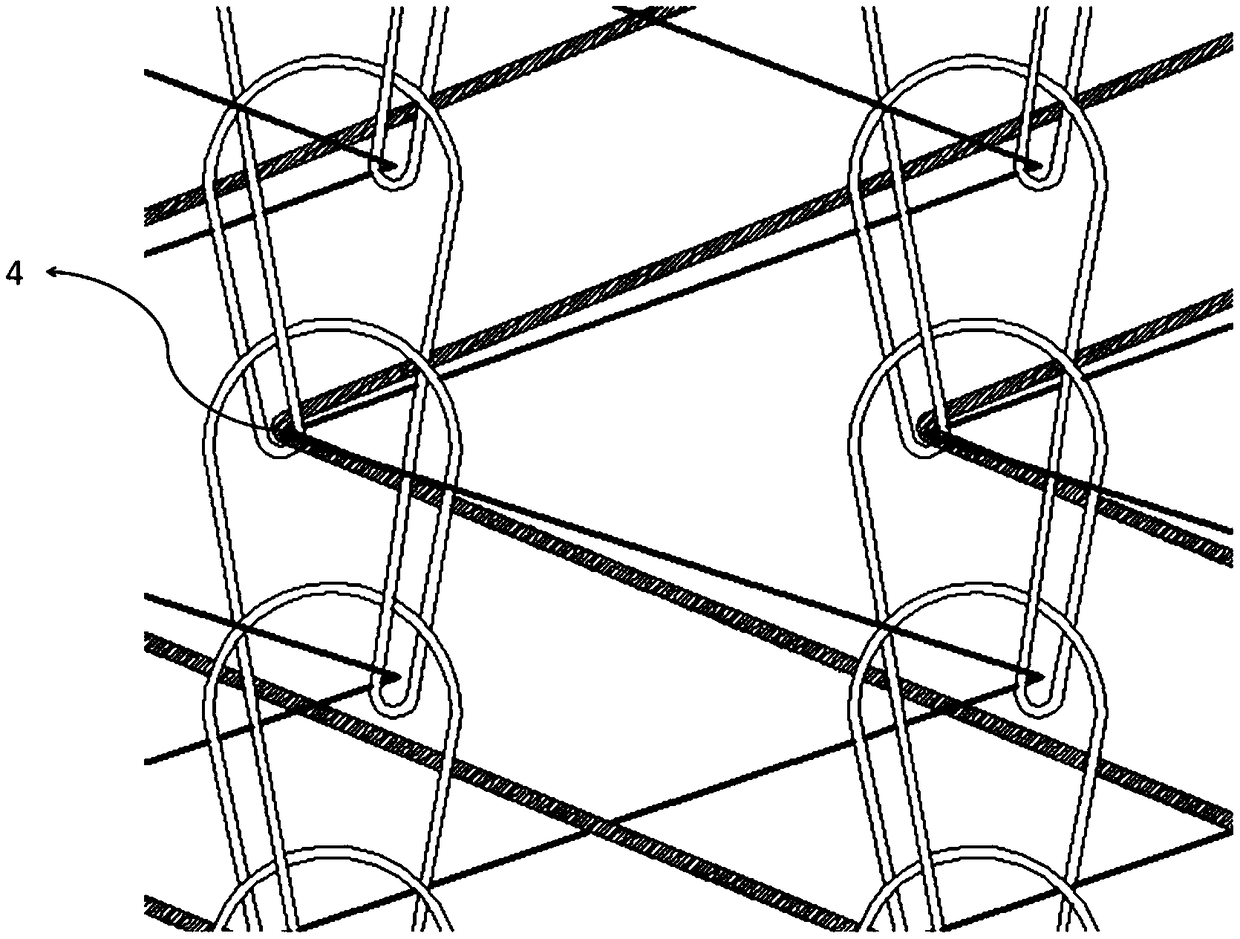

[0025] see Figure 1 to Figure 3 , the warp-knitted car airbag hinge mesh shown in the figure is composed of two mesh areas A, C and a fiber storage area B connecting the two mesh areas A, C, wherein the fiber storage area B is used as a hinge part.

[0026] see Figure 4 , the mesh region A is composited with the automobile plastic body 10 , and the mesh region C is composited with the automobile plastic panel 20 . The weaving structure of the two mesh regions A and C can be the same.

[0027] The entire automobile airbag hinge mesh is finished by warp knitting technology, and is woven together by three sets of yarns 1, 2, 3 or more warp beams (without weft yarns), preferably three sets of yarns, of which the first set of warp yarns 2 is High-strength materials are called main materials, such as: aramid fiber, polyester, carbon fiber, etc. Aramid yarn is the first choice. The function of this group of warp beam yarns is to resist the huge pulling force generated when the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com