Square pipe column butt joint auxiliary construction structure

A pipe column and steel structure technology, which is applied in the field of square pipe column docking auxiliary construction structures, can solve problems such as welding errors, lower overall steel column strength, accurate hoisting and welding difficulties of the upper and lower steel structure box columns, etc., to achieve reduction The effect of cost, simple structure and easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

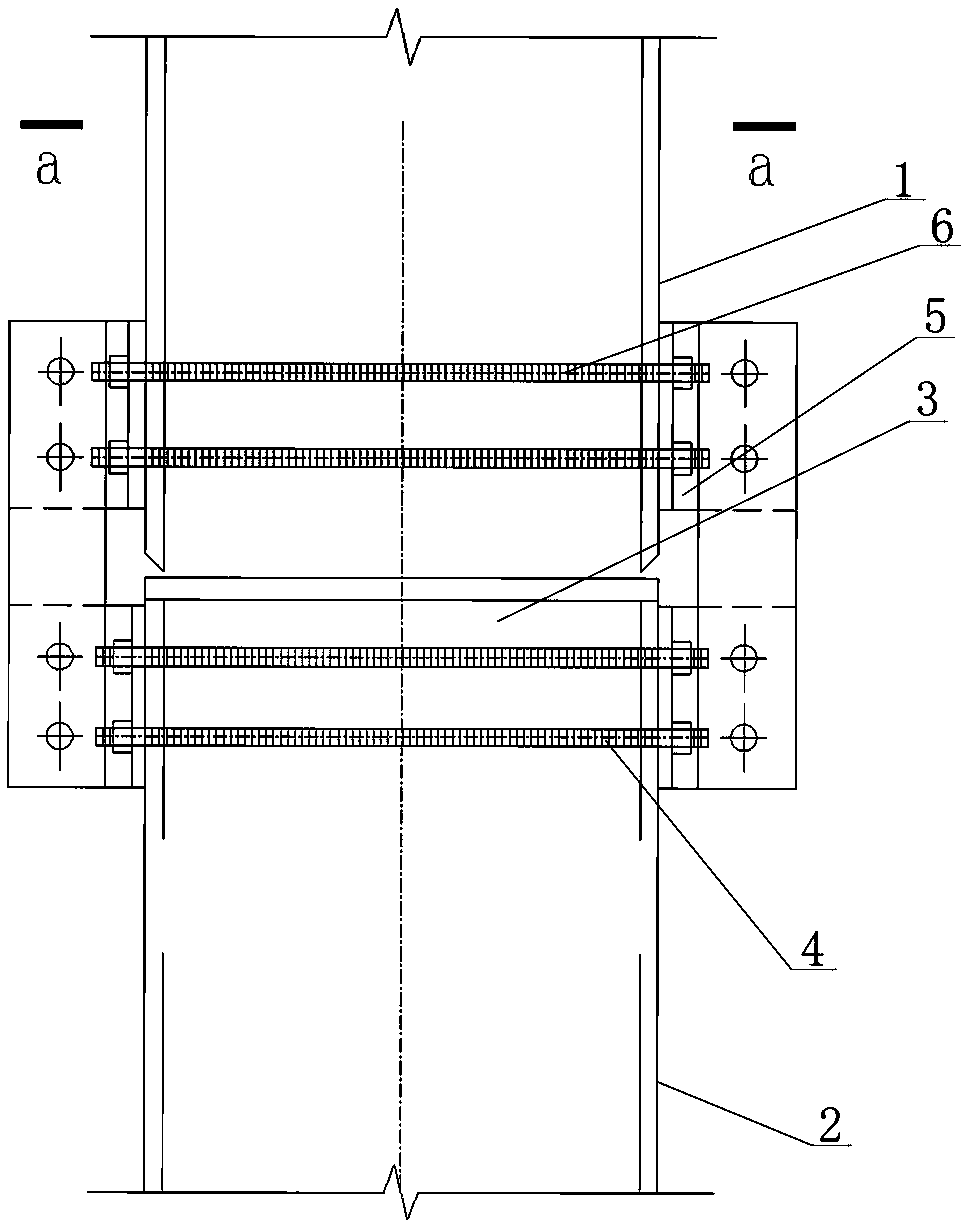

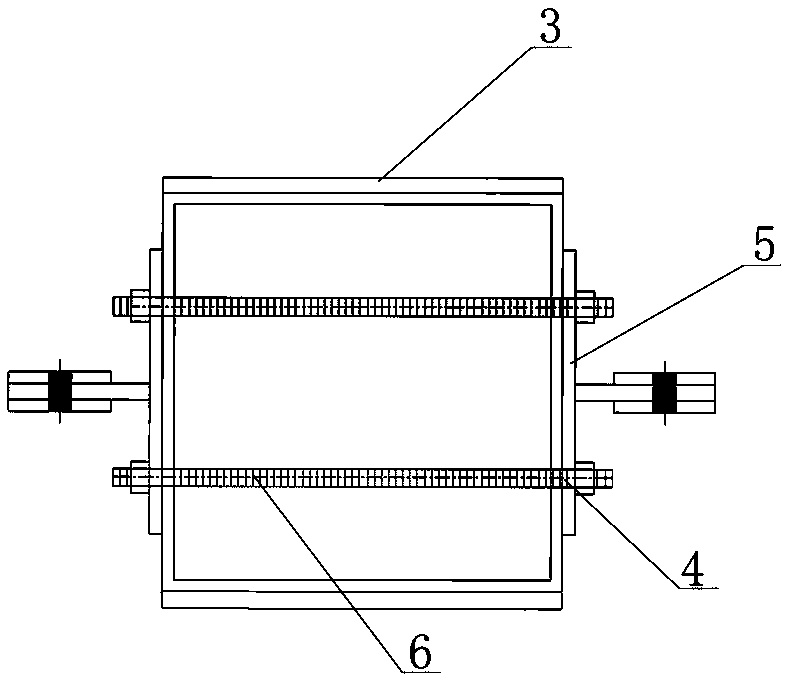

[0009] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 2 As shown in the present invention, a square pipe column butt joint auxiliary construction structure, it includes the upper section square pipe column 1 and the lower section square pipe column 2 that are butted up and down, and the described butt joint auxiliary construction structure includes: The positioning plate 3 at the top of the two facades of the column 2 and the connecting plate 5 respectively arranged on the upper square pipe column 1 and the lower square pipe column 2 with bolt connection holes 4, and the upper square pipe column 1 and the lower square pipe After the columns 2 are aligned, bolts 6 are used to connect the upper and lower square steel columns 1 and 2, and after the installation of the square steel columns is completed, the verticality is corrected and then welded.

[0010] The lower part of the positioning plate 3 of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com