Flow bending type control valve and well system

A technology for controlling valves and flow patterns, which is applied in the direction of production fluid, wellbore/well components, and wellbore/well valve devices, etc., which can solve the problems of low sweep efficiency of injection fluid and premature entry of injection fluid into production wellbore, etc., to achieve Low cost, improved development efficiency, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

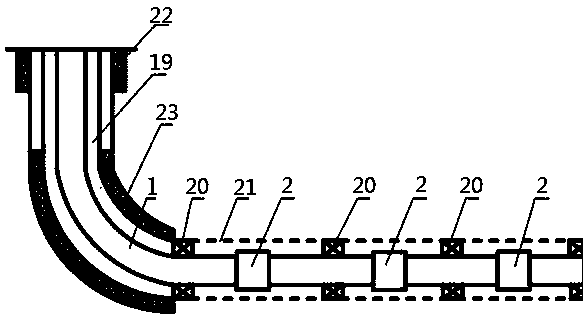

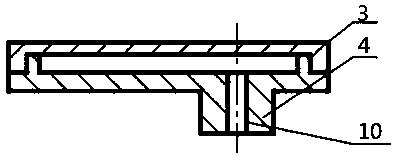

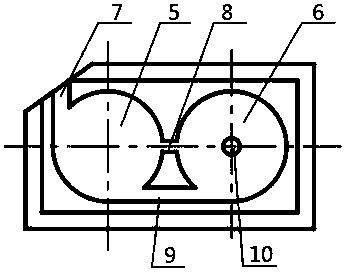

[0027] Example 1, such as Figure 1-Figure 6 As shown in , the present invention is a baffle type control valve and its well system, which is characterized in that: it includes a completion string 1 and a baffle type control valve 2; the heel end of the horizontal section of the completion string 1 is There are multiple groups of baffle control valves 2 that are closed at intervals in the direction of the toe end; the baffle control valve 2 includes a cover plate 3 and a valve body 4, and the cover plate 3 and the valve body 4 are interference fit; the valve body 4 is provided with a circular chamber 5 and a control chamber 6, and the circular chamber 5 is provided with a liquid inlet 7 connected to the outside, and the circular chamber 5 and the control chamber 6 respectively pass through the flow channel A8 and the flow channel B9 is connected; the bottom of the control chamber 6 is provided with a nozzle 10 communicating with the lower end of the control chamber 6 and the v...

Embodiment 2

[0031] Embodiment 2, carry out further optimization design on the basis of embodiment 1, as Figure 7 and Figure 8As shown in , a baffle chamber 11 is provided between the circular chamber 5 and the control chamber 6; the baffle chamber 11 communicates with the circular chamber 5 through the flow channel C12 and the flow channel D13; The chamber 11 communicates with the control chamber 6 through the flow channel E14. The baffle chamber 11 is provided with more than one, and a plurality of baffle chambers 11 are connected in series or in parallel, and the shapes of the baffle chamber 11 and the control chamber 6 are respectively one of geometric figures; The shape of 11 can be any shape such as a circle, a square, etc. The number of baffle chambers 11 can be one or more, and multiple baffle chambers 11 can be connected in parallel or in series in the valve body 4 . When the fluid flows in the baffle chamber 11, the flow velocity and direction are changed, which increases the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com