Coal mine hard roof grouting fracturing method and system

A hard roof and grouting technology, which is applied in ground mining, earth square drilling, underground mining, etc., can solve the problems of hard roof collapse at the end mining section, end hanging disaster, low labor intensity, etc., and achieve the fracturing process Stable, controllable safety issues, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

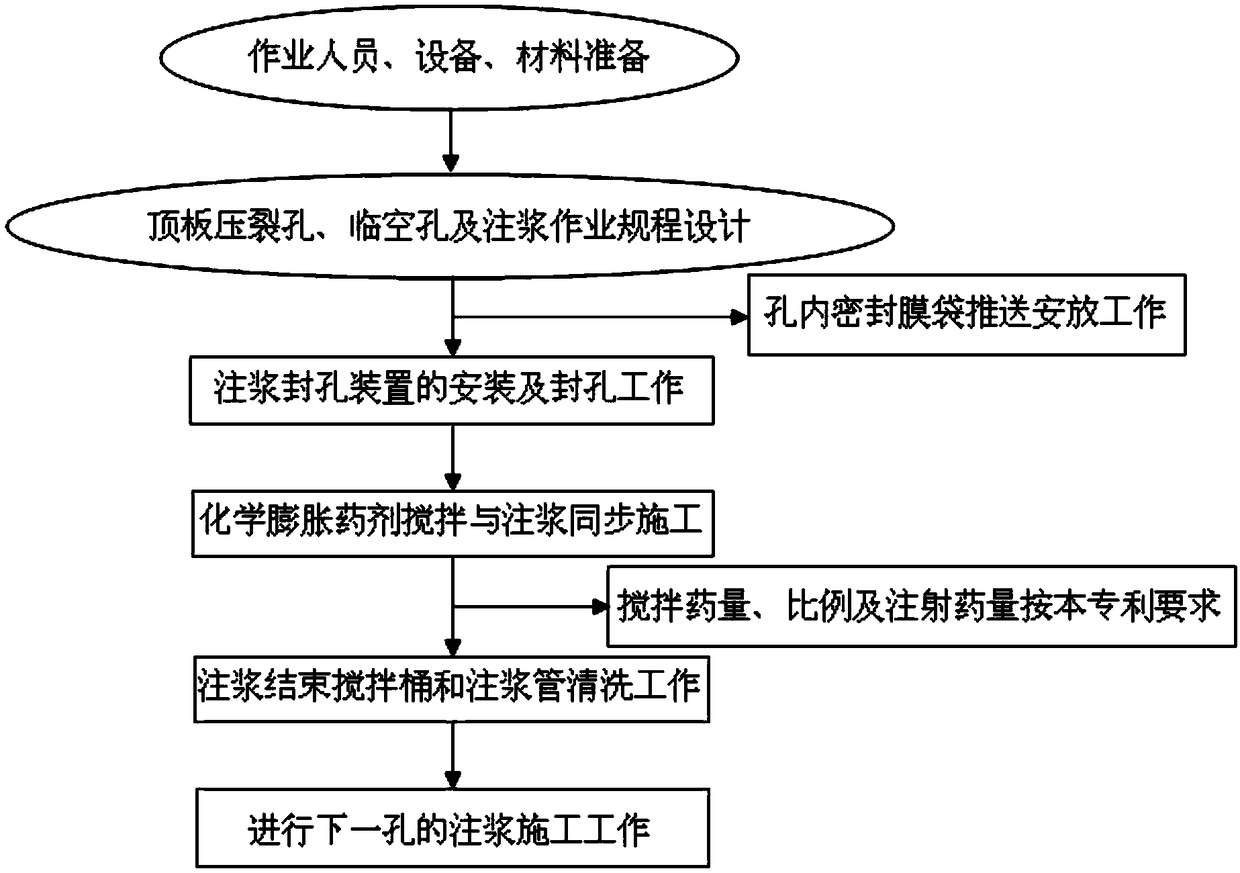

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

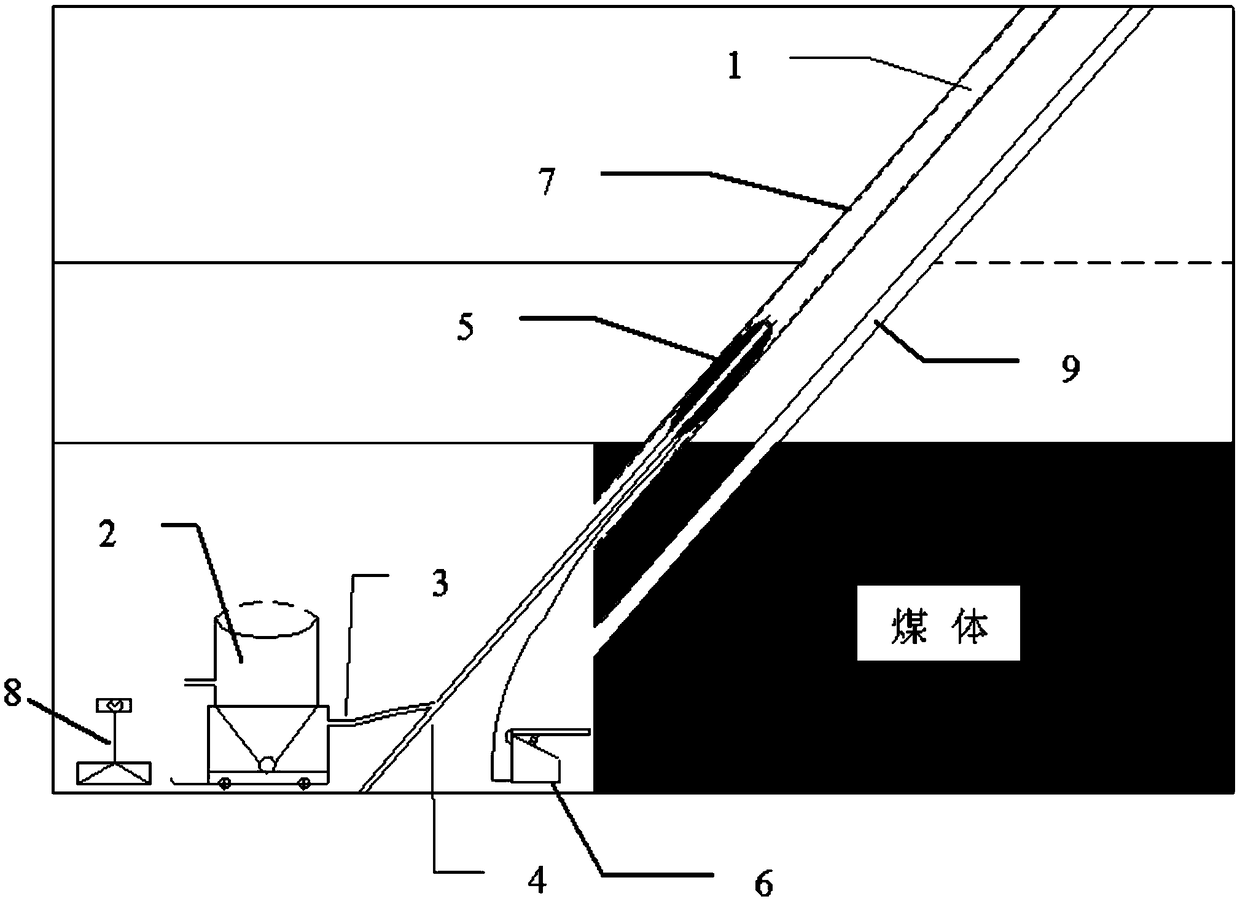

[0027] refer to figure 2 , the coal mine hard roof grouting fracturing system of the present invention comprises agitation-grouting equipment 2, a grouting sealing device, a mobile flatbed car and a sealing film bag push rod, and the agitation-grouting equipment 2 comprises a mixer, a grouting equipment connected in sequence The machine and the grouting pipe 3, the mixer and the grouting machine are all arranged on the mobile flatbed truck, which is convenient to move. The pump 6, the slurry inlet rod 4 are connected with the slurry outlet pipe 3.

[0028] Preferably, the agitator, the grouting machine and the grouting pipe 3 of the present invention are respectively a pneumatic agitator, a pneumatic grouting machine and a high-pressure rubber hose for grouting, and the single-hole stirring capacity of the pneumatic agitator ranges from 81.5L to 172.5L; The grouting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com