Direct driven wind power generation unit

A wind turbine, direct-drive technology, used in wind turbine combinations, wind turbines, wind power generation, etc., can solve the problems of increasing the weight of the generator, reducing the life of the generator, and increasing the manufacturing cost, so as to improve the life and the durability. The effect of load reduction and compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

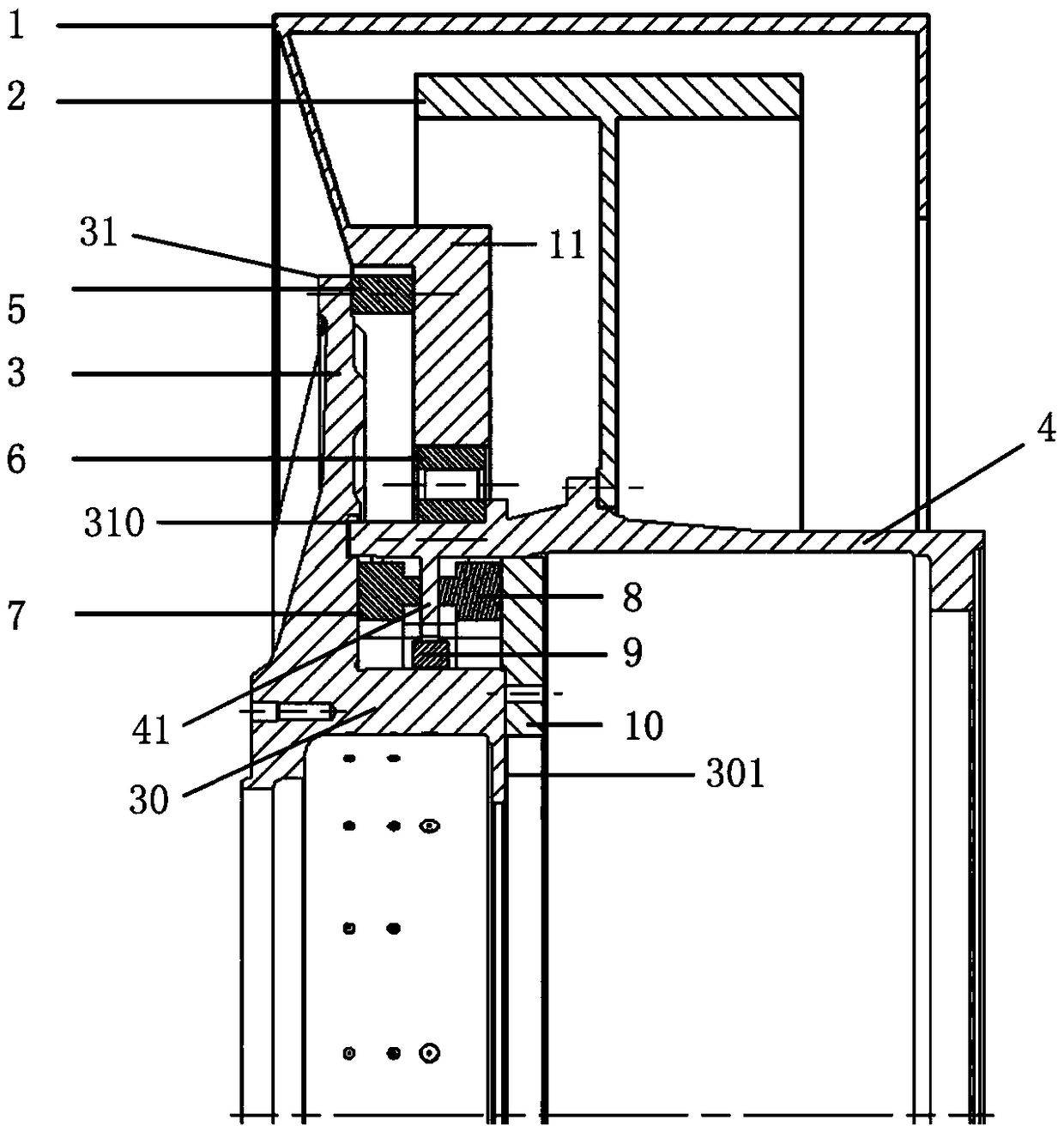

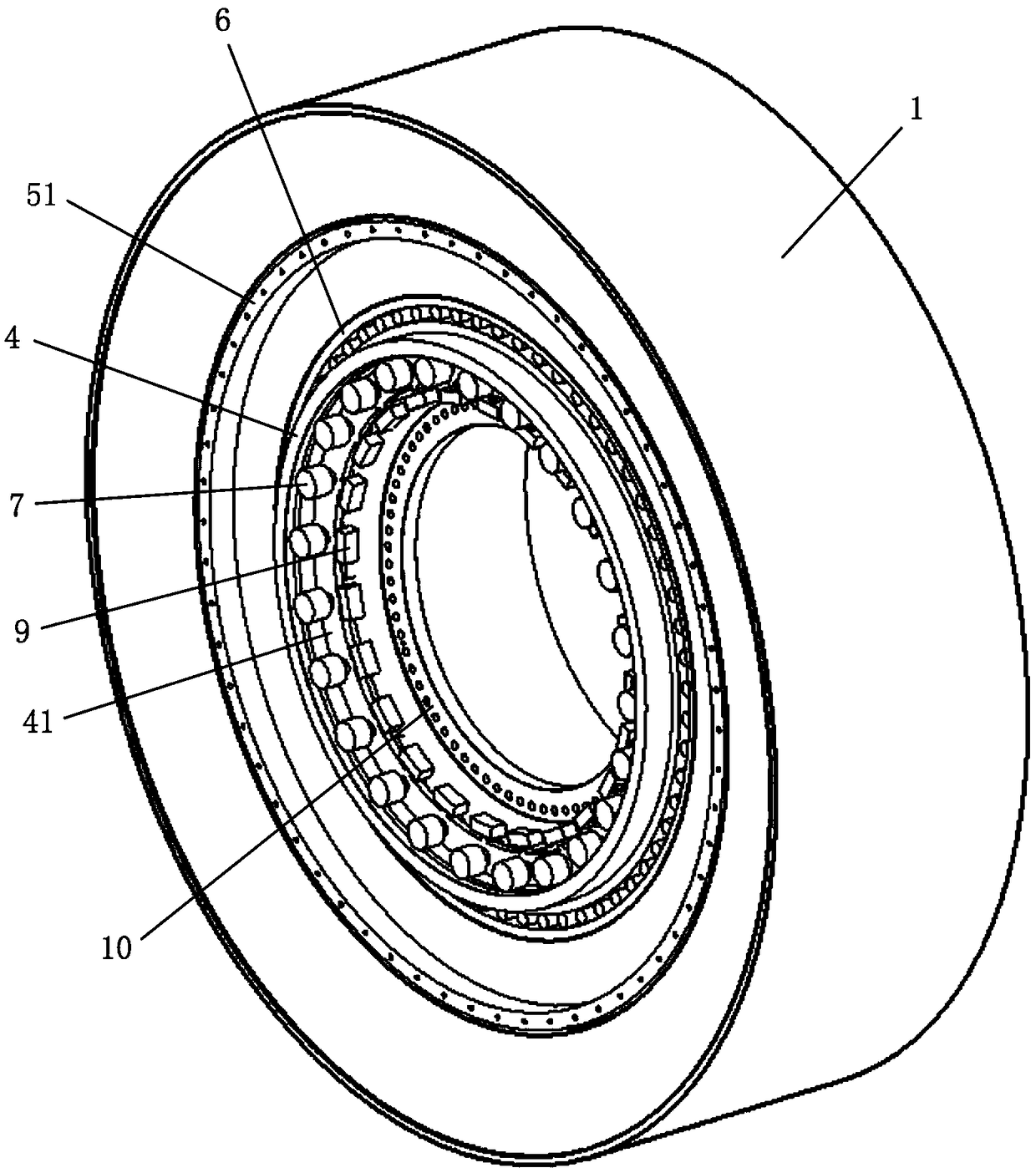

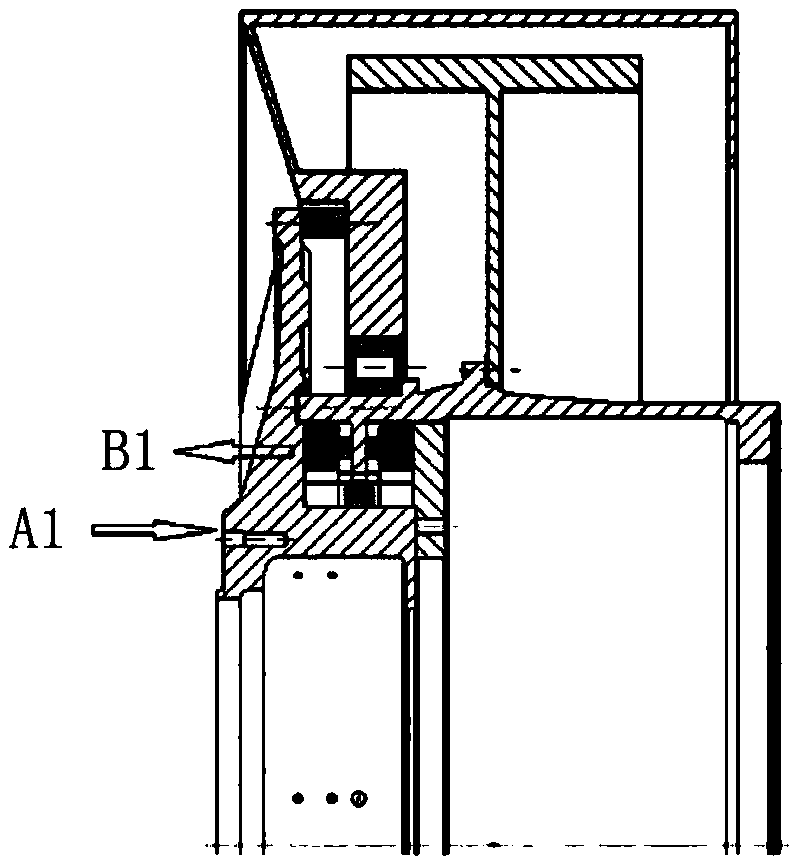

[0033] Hereinafter, a direct-drive wind power generating set according to an embodiment of the present invention will be described in detail with reference to the accompanying drawings.

[0034] Such as figure 1 and figure 2 As shown, in the direct drive wind power generator set according to the embodiment of the present invention, the rotating shaft 3 is connected to the fixed shaft 4 through the first bearing, the rotor 1 of the generator is rotatably mounted to the fixed shaft 4 through the second bearing 6, and the rotating shaft 3 A flexible coupling 5 is arranged between the rotor 1 and the torque is transmitted from the rotating shaft 3 to the rotor 1 through the flexible coupling 5 .

[0035] The shaft 3 is used to input torque to the rotor 1 . The rotating shaft 3 can be integrally formed with the hub on which the blades are installed, or rigidly connected to the hub on which the blades are installed, so that when the wind drives the blades to rotate, the hub and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap