Special dustproof telescopic cylinder

A technology of telescopic oil cylinders and oil cylinders, applied in the direction of fluid pressure actuating devices, etc., can solve the problems of low cost of flange parts, difficulty in achieving uniform strength of welding positions, low efficiency, etc., and achieve the effect of good overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

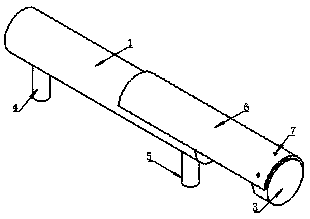

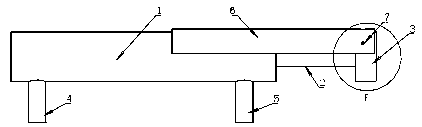

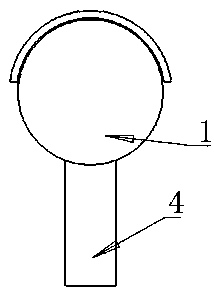

[0018] Such as Figure 1 to Figure 6 As shown, a special dust-proof telescopic oil cylinder can be used with automatic welding equipment for pipe pile flanges. It sets an arc-shaped dust-proof safety connection cover on the upper end of the clamping connection block structure. When the flange parts are welded, it can effectively prevent welding dust from sticking to the telescopic movement control shaft, so that the overall stability of the oil cylinder is better, and the flange welding is safer, which can increase the service life of the oil cylinder structure during use. Make it more safe during telescopic movement, the length of the dust-proof safety connection cover is the same as the total length of the telescopic movement control shaft, so that it has a better overall dust-proof effect when in use. It includes a cylindrical oil cylinder main structure 1. A cylindrical telescopic movement control shaft 2 is provided at the right center of the oil cylinder main structure 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com