High-efficiency condensed water recovery device

A technology for recycling device and condensate water, applied in the field of water treatment, can solve the problems of inefficient energy-saving evaporation, ordinary condensate water recycling device can not self-supply water and drainage, etc., to achieve the effect of saving energy, improving practical performance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

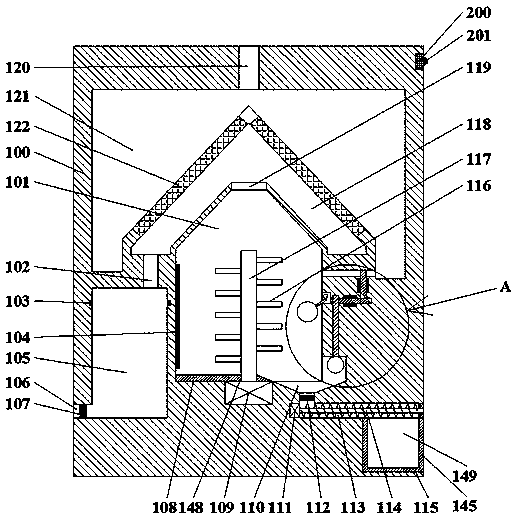

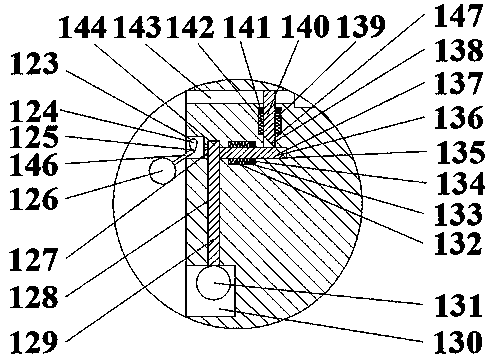

[0019] Such as Figure 1-Figure 2 As shown, a high-efficiency condensed water recovery device of the present invention includes a fuselage 100 and a first cavity 101 disposed in the fuselage 100, and a second cavity is disposed in the top wall of the first cavity 101 118, a first connection hole 119 is communicated between the first cavity 101 and the second cavity 118, and a third cavity 121 is annularly set in the top wall of the second cavity 118. The top wall of the three cavities 121 is provided with a water inlet 120 connected to the outside, and a condensing plate 122 is fixedly installed between the second cavity 118 and the third cavity 121, and the first cavity 101 and the third cavity 121 are fixedly installed. A second connection hole 143 is provided in communication between the second cavities 118, and a fourth cavity 123 opening to the left is provided in the right end wall of the first cavity 101, and the fourth cavity 123 can be The rotation is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com