A tracking three-dimensional scanning method and system in a vibrating environment

A three-dimensional scanning and tracking technology, applied in the field of optical scanning, can solve the problems of cumbersome pasting of marking points, failure to meet the measurement requirements, and increase the workload of scanning and measurement, etc., to achieve expandable working space, wide application range, and convenience The effect of 3D reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

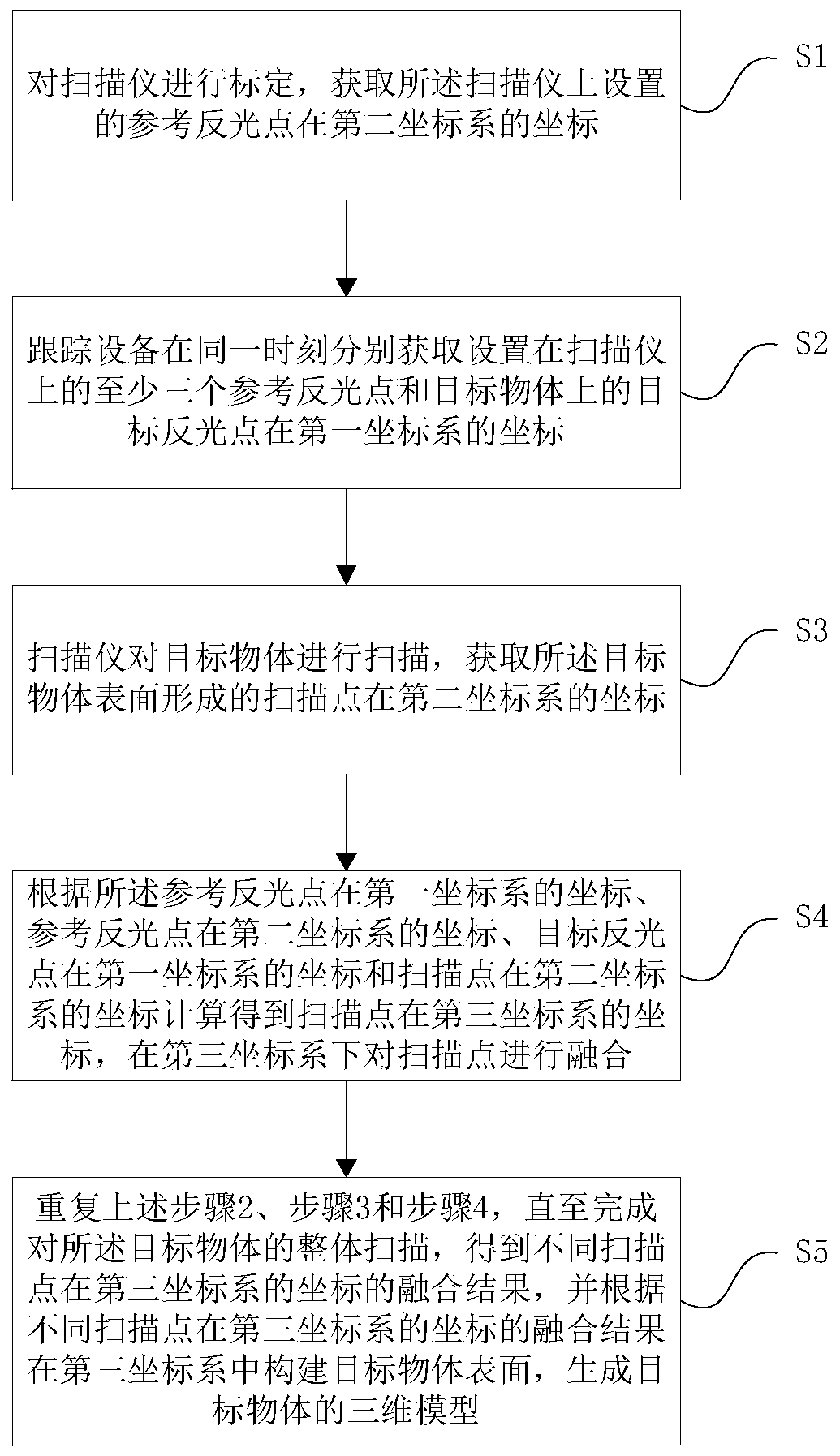

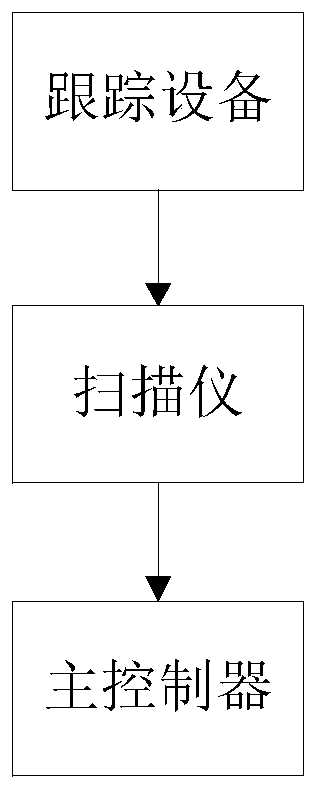

[0068] Such as figure 1 As shown, a tracking type three-dimensional scanning method in a vibration environment includes the following steps:

[0069] Step 1: Calibrate the scanner, and obtain the coordinates of the reference reflective point set on the scanner in the second coordinate system;

[0070] Step 2: The tracking device respectively obtains the coordinates of at least three reference reflective points set on the scanner and the target reflective point on the target object in the first coordinate system at the same time;

[0071] Step 3: The scanner scans the target object, and obtains the coordinates of the scanning point formed on the surface of the target object in the second coordinate system;

[0072]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com