Transformer vibration noise source positioning system and method

A vibration noise and transformer technology, applied in the field of transformer vibration and noise source positioning system, can solve the problems of not considering low-frequency noise, difficulty in decoupling of sub-structure noise transmission, complex transformer structure, etc., and achieve the effect of easy judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

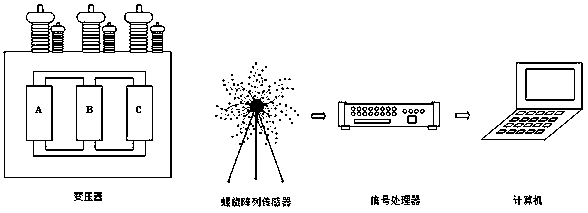

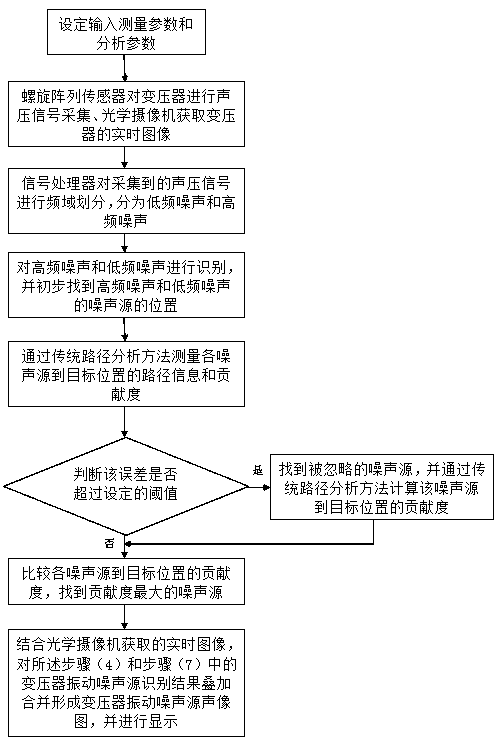

[0051] In Embodiment 1, a transformer vibration and noise source location method adopts the following steps:

[0052] (1) Set the input measurement parameters and analysis parameters on the computer, select the beamforming algorithm and the near-field acoustic holography algorithm, and input the sampling interval and the distance between the spiral array and the transformer;

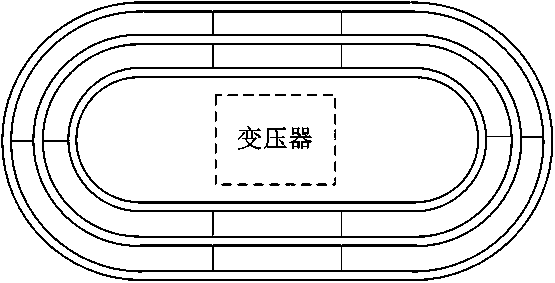

[0053] (2) Start the traction motor, the spiral array sensor moves on the guide rail at a constant speed, and collects the vibration noise of the transformer around the transformer; during the movement of the spiral array sensor, the spiral array sensor continuously collects sound pressure signals, and the optical camera captures real-time images of the transformer;

[0054] (3) The signal processor divides the collected sound pressure signals into the frequency domain, and divides them into low-frequency signals less than 350HZ and high-frequency signals greater than 350HZ;

[0055] (4) Use the beamform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com