System and method for realizing spray shape detection and imaging in closed cavity

A technology of internal spraying and closed chamber, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of destroying the internal static characteristics of the engine, difficult to detect equipment, complex shape and structure, etc., to improve clarity and quality, prevent interference, Strong penetrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

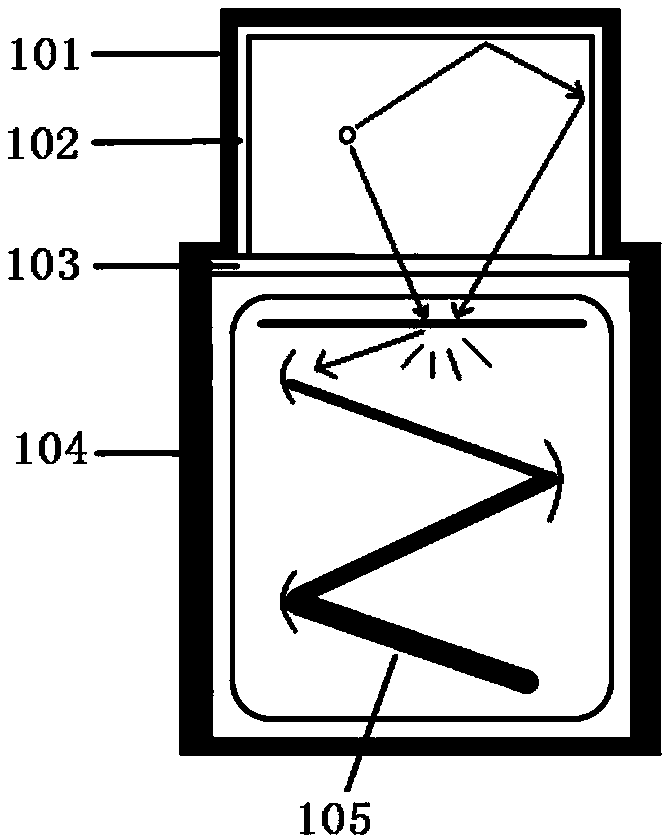

[0030] The present invention adopts the following measures: the radionuclide in the positron liquid marks the fuel; adding a combustion residue remover removes the interference caused by the combustion residue rays; On this basis, the shape of the oil mist ejected from the fuel injector in the engine cylinder is detected and three-dimensionally imaged, and the spray space is extracted as a region of interest (VOI) by image segmentation for further processing, thus obtaining Spray shape and working conditions in the engine cylinder.

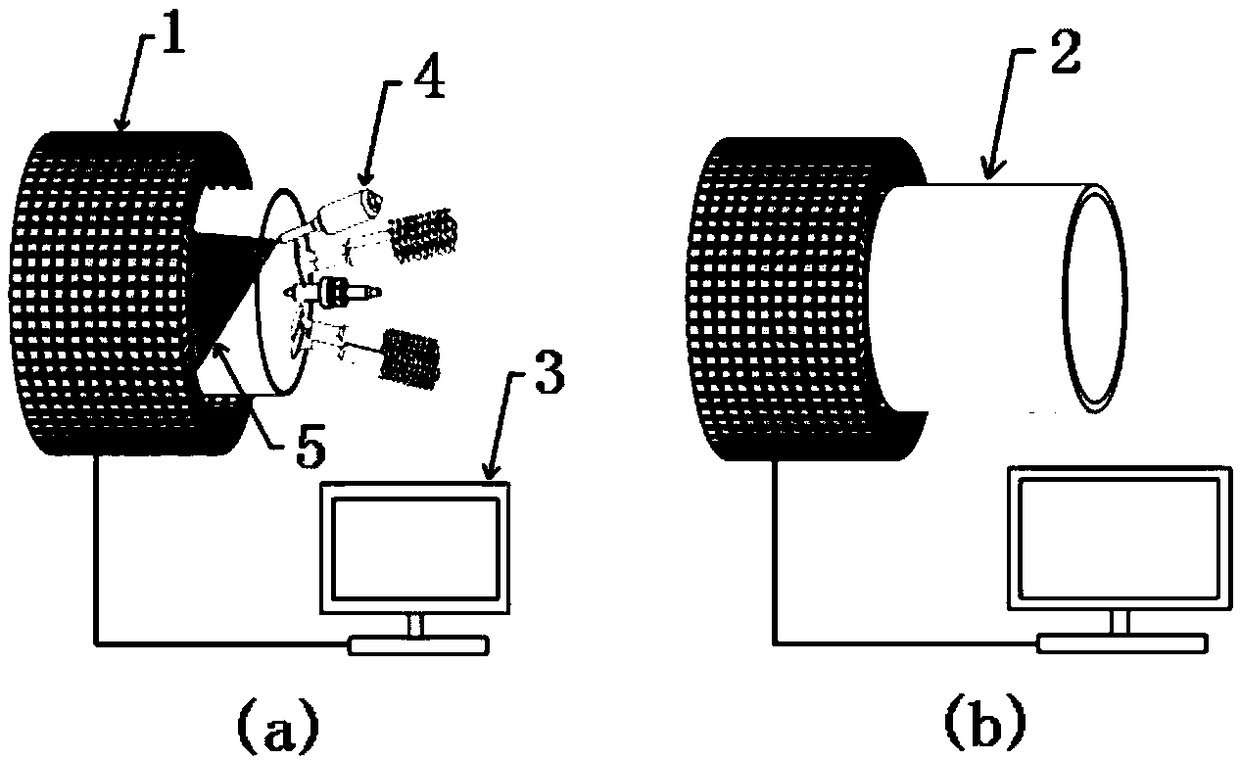

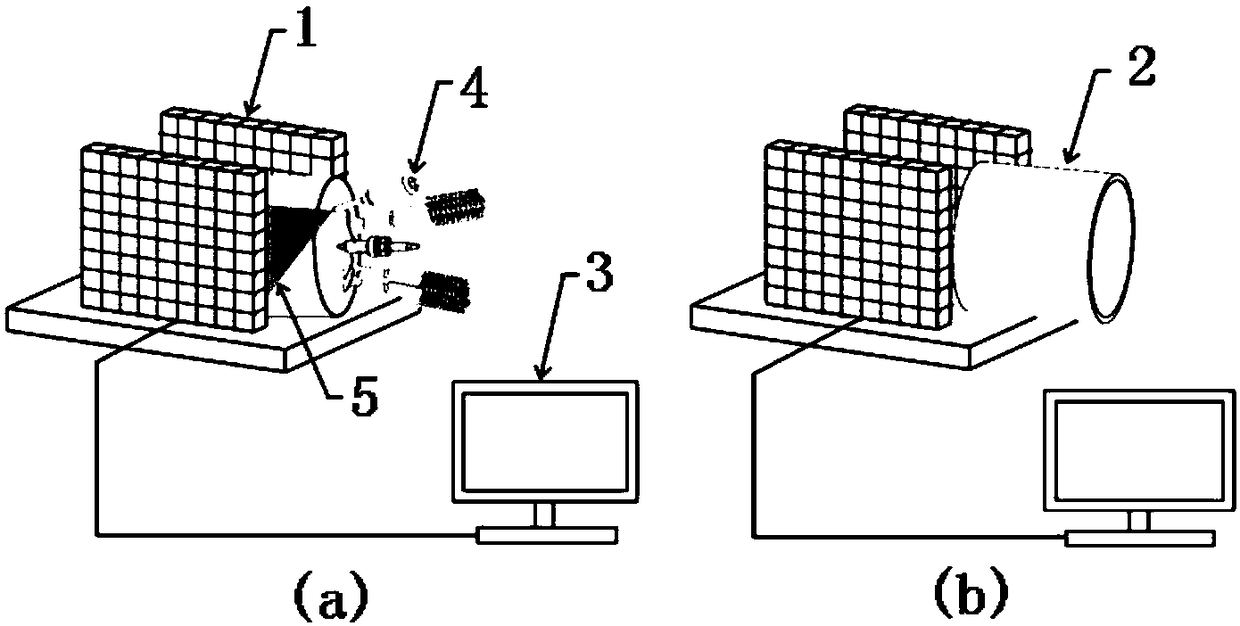

[0031] Such as figure 1 and figure 2 A system for detecting and imaging the spray shape in a closed cavity is shown, including an engine, a gamma photon detector 1, a gamma photon shielding ring 2, and an imaging device 3. There is a marked carrier solvent mixture in the engine oil cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com