STL file-based precision machine tool computer-aided tolerance analysis method

A computer-aided precision machine tool technology, which is applied in the field of precision machine tool tolerance analysis and error state optimal estimation, can solve problems such as insufficient precision and excessive precision, and achieve the effect of reducing workload and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0049] Aiming at the problems of relying on engineer experience and insufficient precision and excess precision in the existing machine tool tolerance analysis process, the present invention invents a precision machine tool tolerance analysis method considering measurement and adjustment process, and the method includes a state space model of the machine tool assembly process.

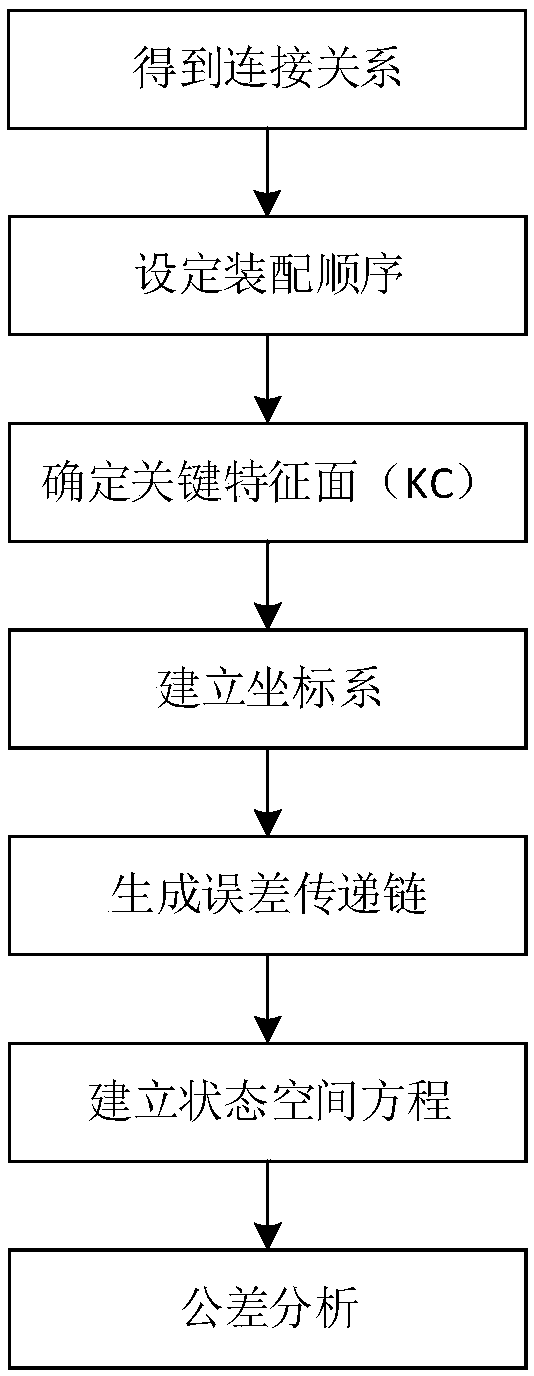

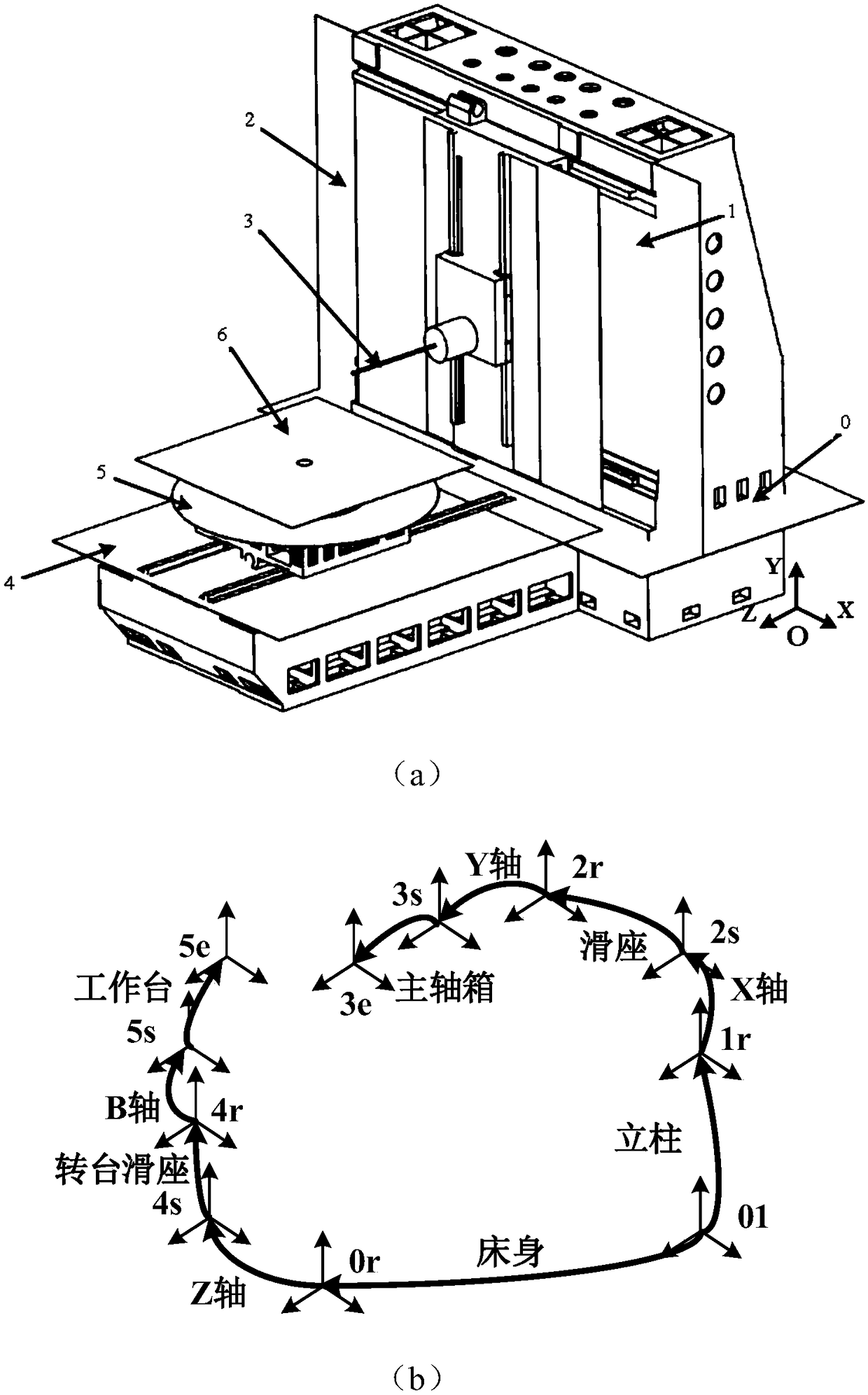

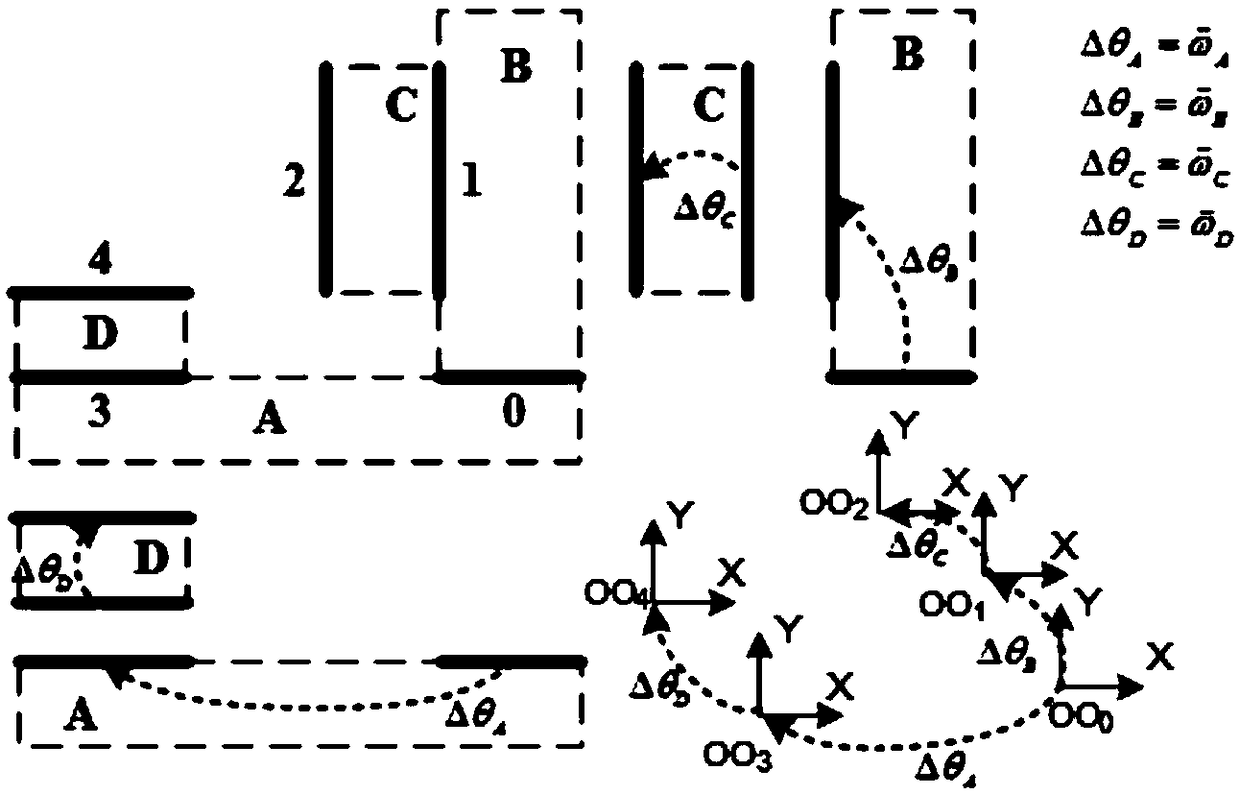

[0050] The process flow of the precision machine tool computer-aided tolerance analysis method based on the STL file provided by the present invention is as follows: figure 1As shown, methods such as generating error transfer chains and establishing state space equations are included. According to the tolerance analysis steps shown in the flow chart, the accuracy prediction of the machine tool can be realized. The specific steps are:

[0051] 1) For a precision machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com