A Estimation Method of Working Fluid Charge in Organic Rankine Cycle System

A technology of circulating system and circulating working fluid, which is applied in the direction of design optimization/simulation, special data processing application, etc., can solve problems such as the difficulty in solving the distribution of working fluid in the system, and achieve the effect of simple structure, simple and accurate calculation, and better adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

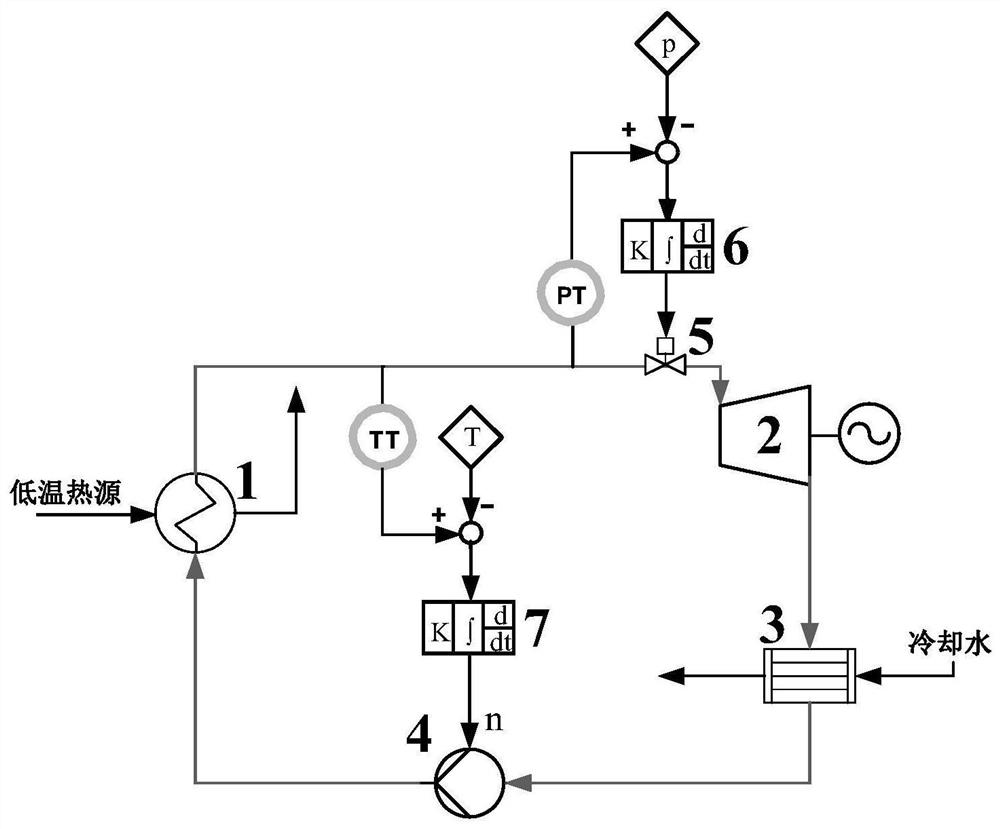

[0092] Example 1 When the heat source changes, the outlet temperature of the evaporator is controlled by adjusting the flow rate of the working fluid pump. ORC system adopts constant pressure operation, the pressure before the expander inlet valve is controlled by the valve opening, the control adopts PI controller, and the transfer function includes proportional gain K 7 and integration time T 5 , which can be expressed as:

[0093]

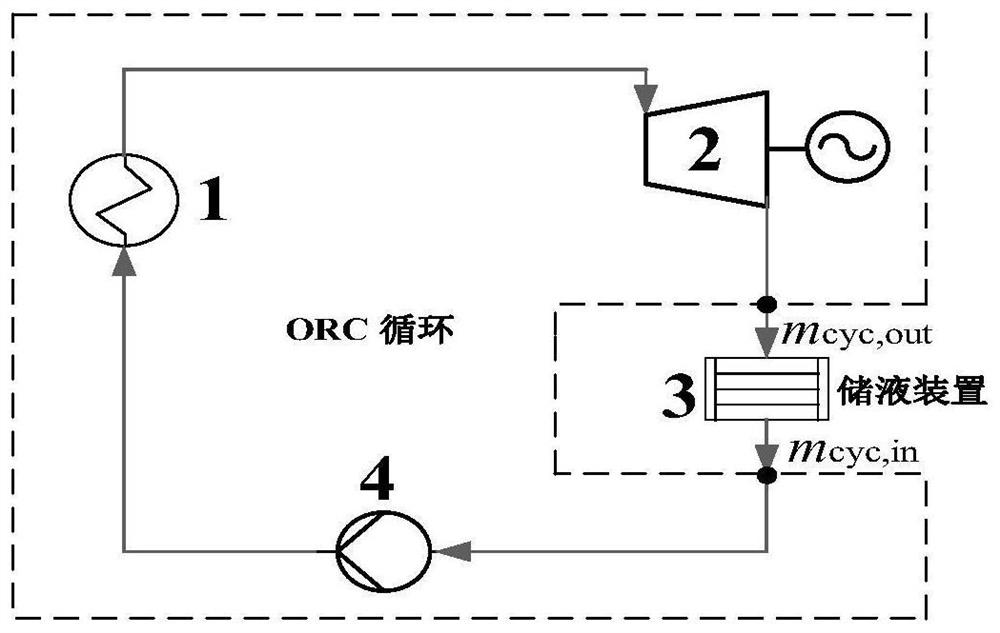

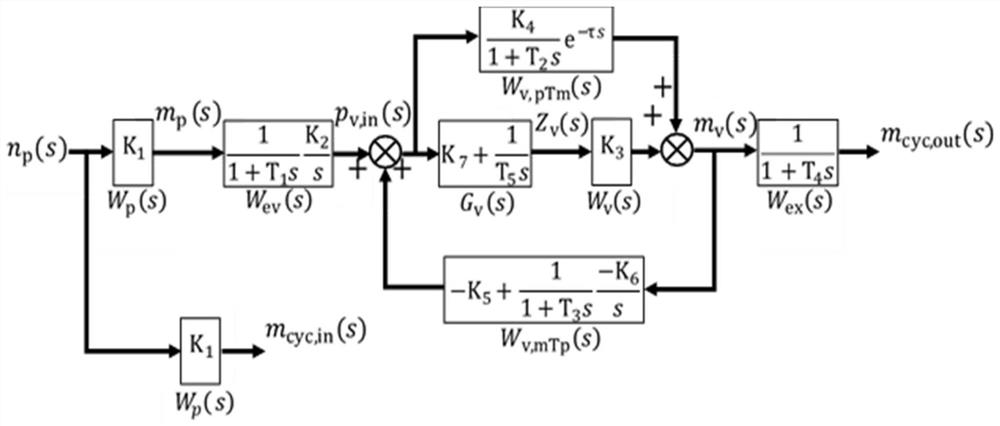

[0094] When the speed of the working medium pump changes with the heat source, the dynamic model of the working medium exchange flow between the ORC cycle and the liquid storage device expressed by the transfer function is as follows: image 3 shown.

[0095] based on image 3 The dynamic model of embodiment 1 ORC cycle is discharged into the liquid storage device working medium flow rate m cyc,out Response to working fluid pump speed n p The varying transfer function can be expressed as:

[0096]

[0097] Example 1 The liquid storag...

Embodiment 2

[0113] In Example 2, when the heat source changes, the outlet temperature of the evaporator is controlled by adjusting the flow through the inlet valve of the expander. The ORC system adopts constant pressure operation, the pressure before the inlet valve of the expander is controlled by the speed of the working fluid pump, the control adopts the PI controller, and the transfer function includes the proportional gain K 8 and integration time T 6 , which can be expressed as:

[0114]

[0115] When the opening of the inlet valve of the expander changes with the fluctuation of the heat source, the dynamic model of the flow rate of the working medium exchange between the ORC cycle and the liquid storage device expressed by the transfer function is as follows: Figure 7 shown. based on Figure 7 The dynamic model of the fluid storage device injected into the ORC cycle flow rate m cyc,in The transfer function in response to the change of the inlet valve opening of the expande...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com