Device and method for testing performance degradation caused by transistor lattice deformation

A technology of a testing device and a testing method, applied in the field of microelectronics, can solve the problems of inaccurate calculation of the lattice deformation of the transistor, uneven stress on the transistor, uneven stress on the chip, etc. The effect of overcoming the limited range of mechanical stress and improving the range of mechanical stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

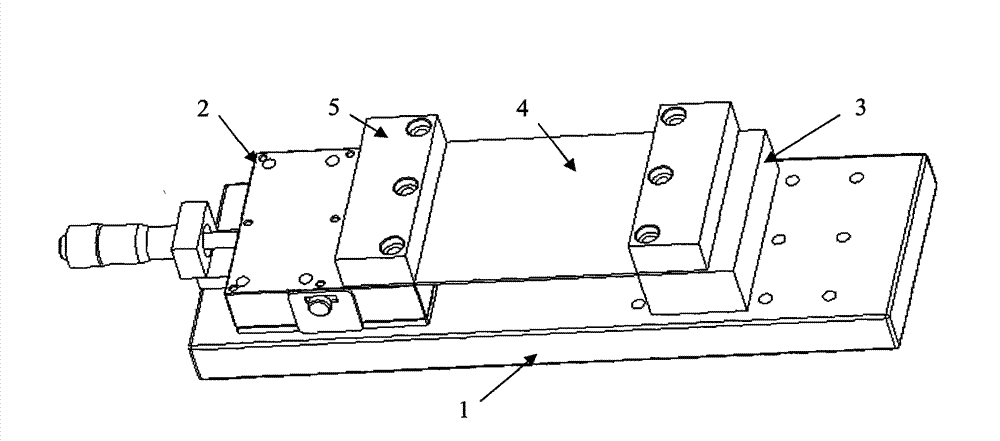

[0035] Refer to attached figure 1 , a test device for performance degradation caused by transistor lattice deformation, including five parts: 1 is a base, 2 is a precision displacement platform, 3 is a spacer, 4 is a carrier, and 5 is a pressing block. in,

[0036]The cuboid base 1 is located at the bottom of the device, and one end is provided with two rows and two columns of four screw holes, which are connected with the precision displacement platform 2 on it with screws; the other end is provided with four rows and three columns of twelve screw holes. When the invention fixes the spacer 3, it can be connected with the spacer 3 on it with screws through one row of screw holes according to the specific lattice deformation test requirements. In the embodiment of the present invention, the spacer 3 is fixed on a row of screw holes on the side closest to the precise displacement platform 2 with screws.

[0037] The precision displacement platform 2 is located on the upper lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com