Method and device for calculating parameters of workshop vibration absorbers

A shock absorber and workshop technology, applied in the direction of calculation, instrumentation, design optimization/simulation, etc., can solve problems such as result errors, high requirements for software use ability, cumbersome drawing, etc., and achieve the effect of simplifying the process of parameters and rapid calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

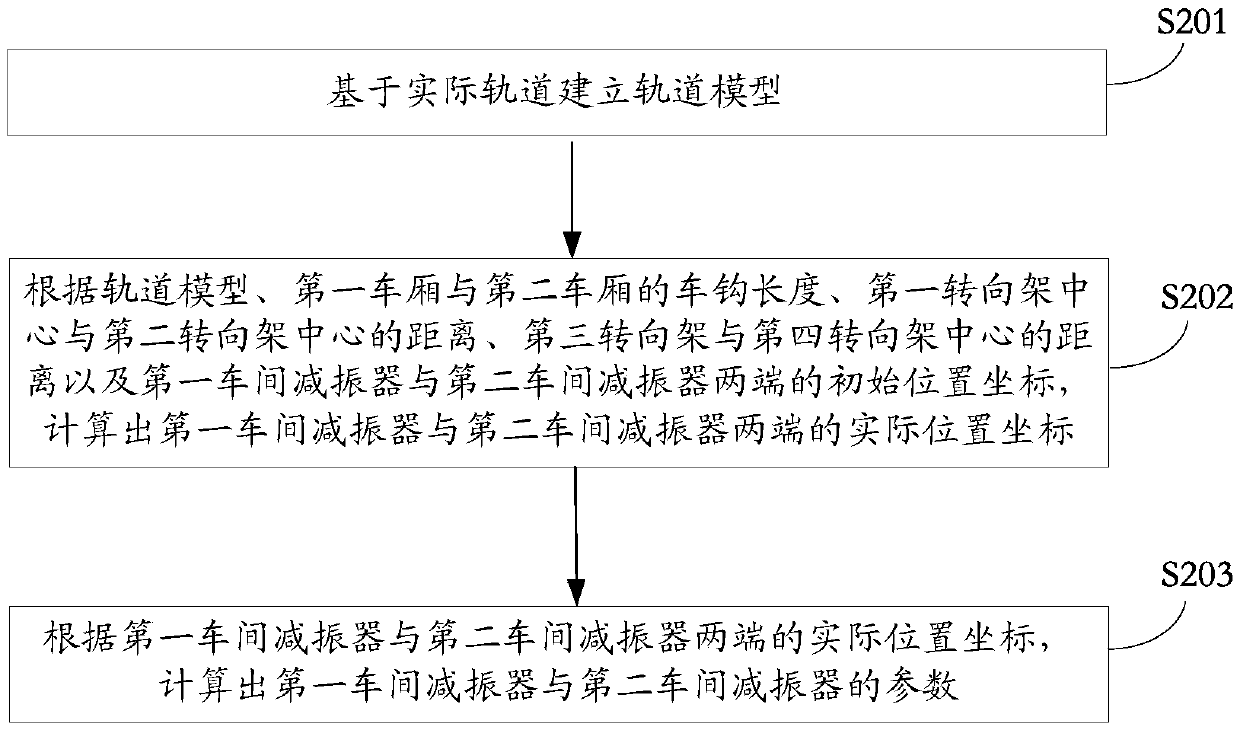

Method used

Image

Examples

Embodiment Construction

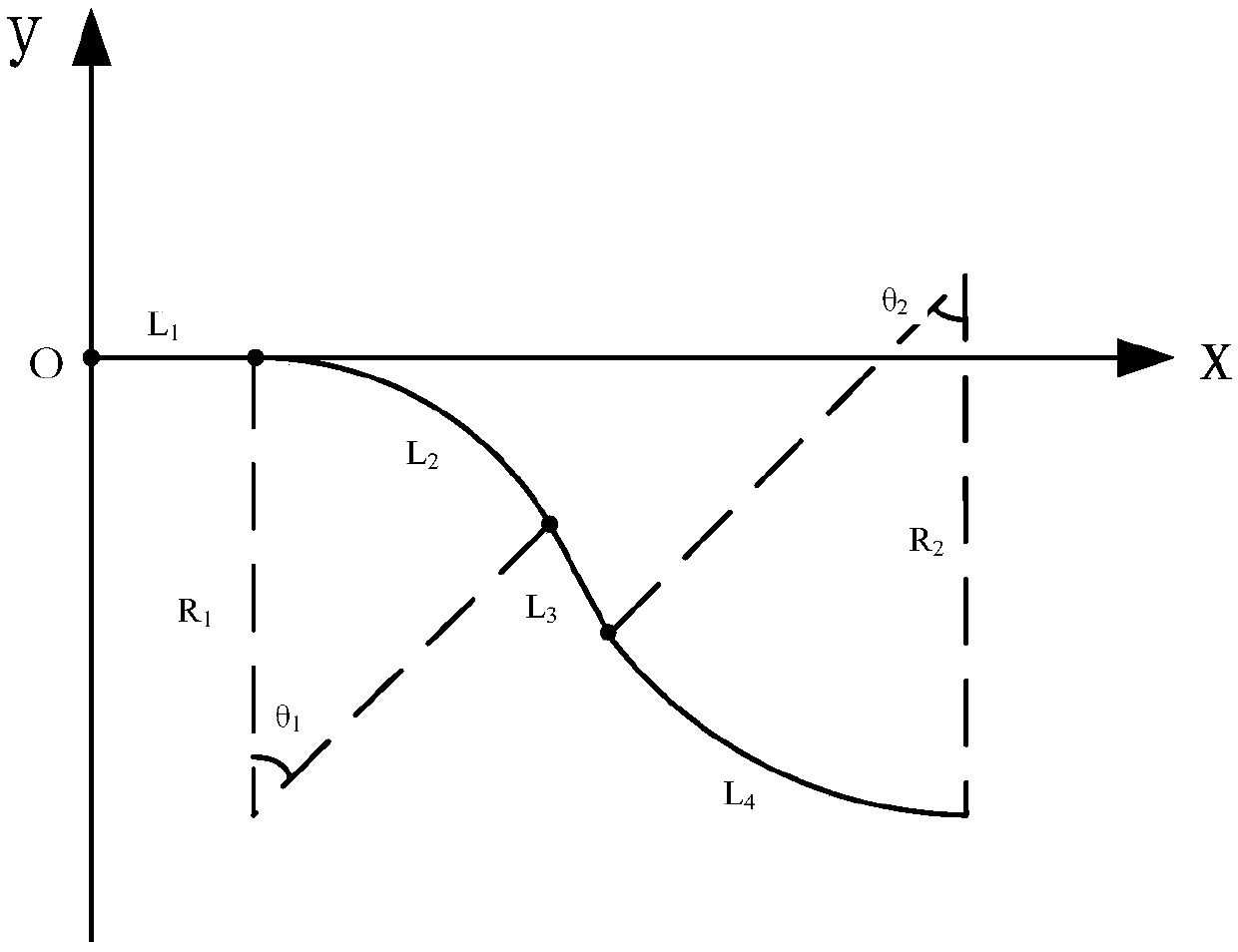

[0051] In the existing technical solutions, CAD geometric drawing method, Catia or Simpack simulation analysis method is usually used to determine whether the expansion and contraction of the workshop shock absorber when the train passes through the curved line exceeds the allowable limit of the workshop shock absorber. Expansion and expansion range, so as to check whether the stretching and shrinking capacity of the shock absorber in the workshop can meet the needs of the train passing through the curved line. This requires technicians to draw for each road condition (straight line plus curve, curve, reverse curve, etc.). The existing technology usually only considers the expansion and contraction of the shock absorber in the workshop when the train passes through a special position. The amount of expansion and contraction of the shock absorber on the workshop. But in fact, when the train is running on a curve, when the expansion and contraction of the shock absorber is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com