Finite element modeling method of macroscopic thermal stress field based on self-healing effect of laser stereoforming

A technology of laser three-dimensional forming and modeling method, applied in special data processing applications, design optimization/simulation, etc., can solve the problems of errors, without considering the influence of deposition thickness, temperature field, stress field and deformation, etc., to improve accuracy It has the effect of reducing the deformation and stress of laser three-dimensional forming, and has a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

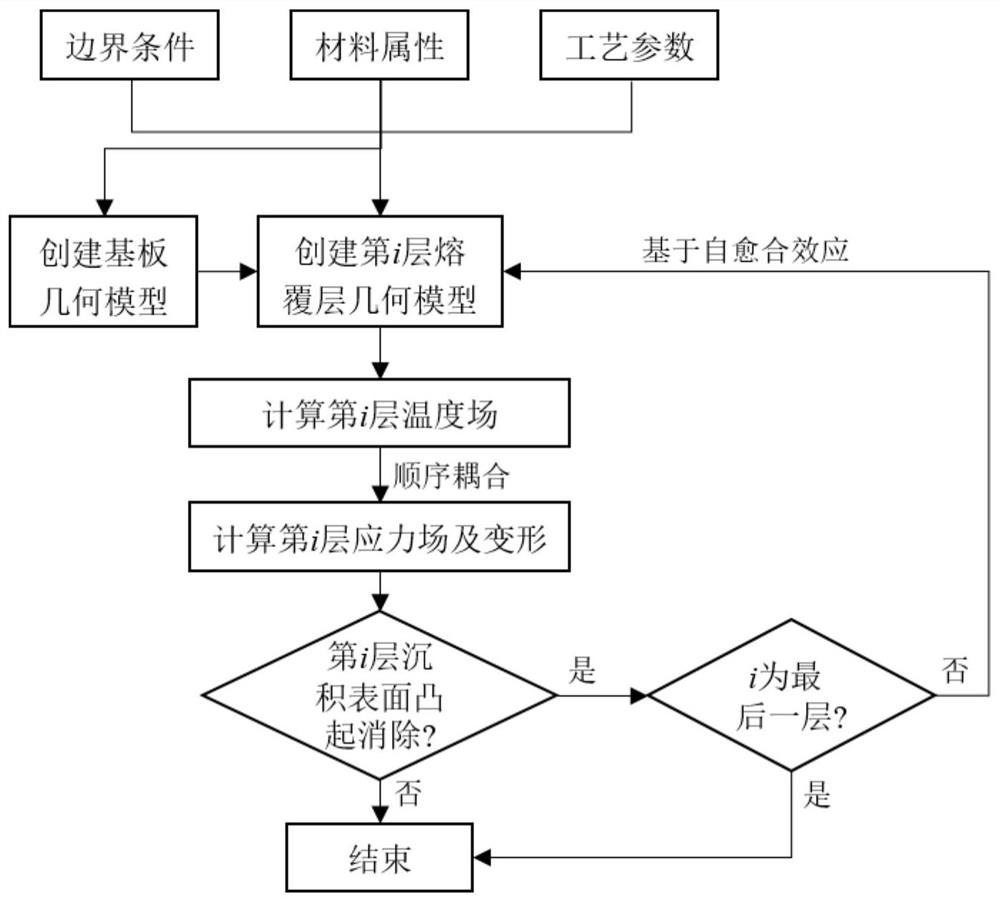

[0041] The macro thermal stress field finite element modeling method based on the self-healing effect of laser three-dimensional forming in the present invention is realized through the following technical solutions:

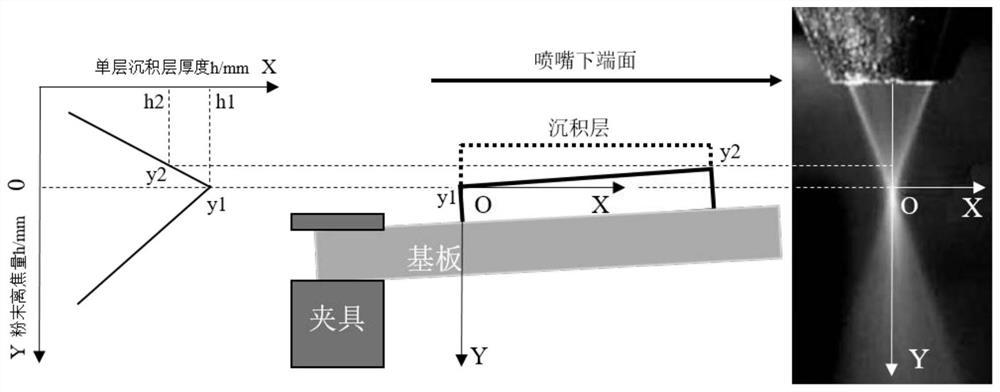

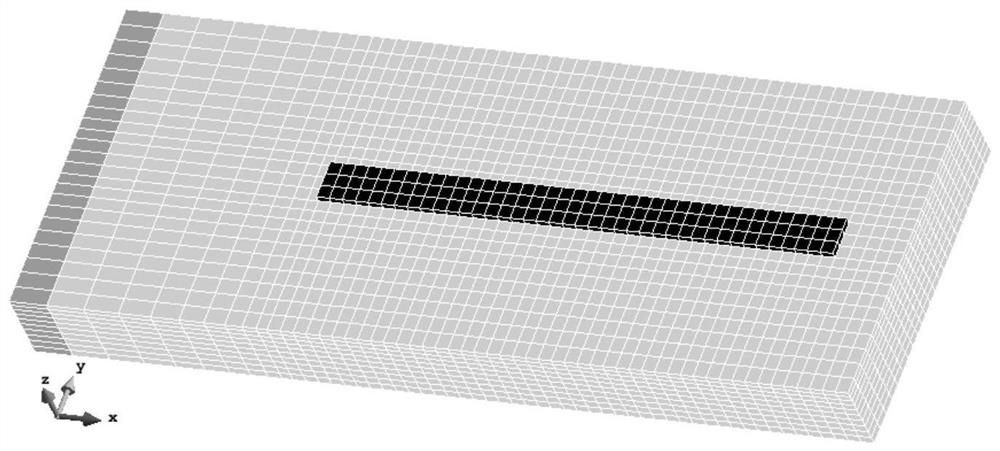

[0042] Step 1: Establish a thermal-mechanical coupling model for unilateral clamping of the laser three-dimensional forming substrate; create a geometric model of the substrate, divide the geometric model of the substrate into a reasonable grid, and finally assign material properties to the substrate. And perform mechanical constraints on one end of the substrate, set mechanical boundary conditions and processing parameters.

[0043] Step 2, establish the thermal-mechanical coupling model of the cladding layer of the i-th layer of the laser three-dimensional forming component; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com