Assessment method for coupling state of process industrial electromechanical system based on network structure entropy

A network structure and electromechanical system technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as lack of research methods, redundant monitoring information, and insufficiency, so as to improve the level of safe service and achieve refinement The effect of controlling and reducing computational complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

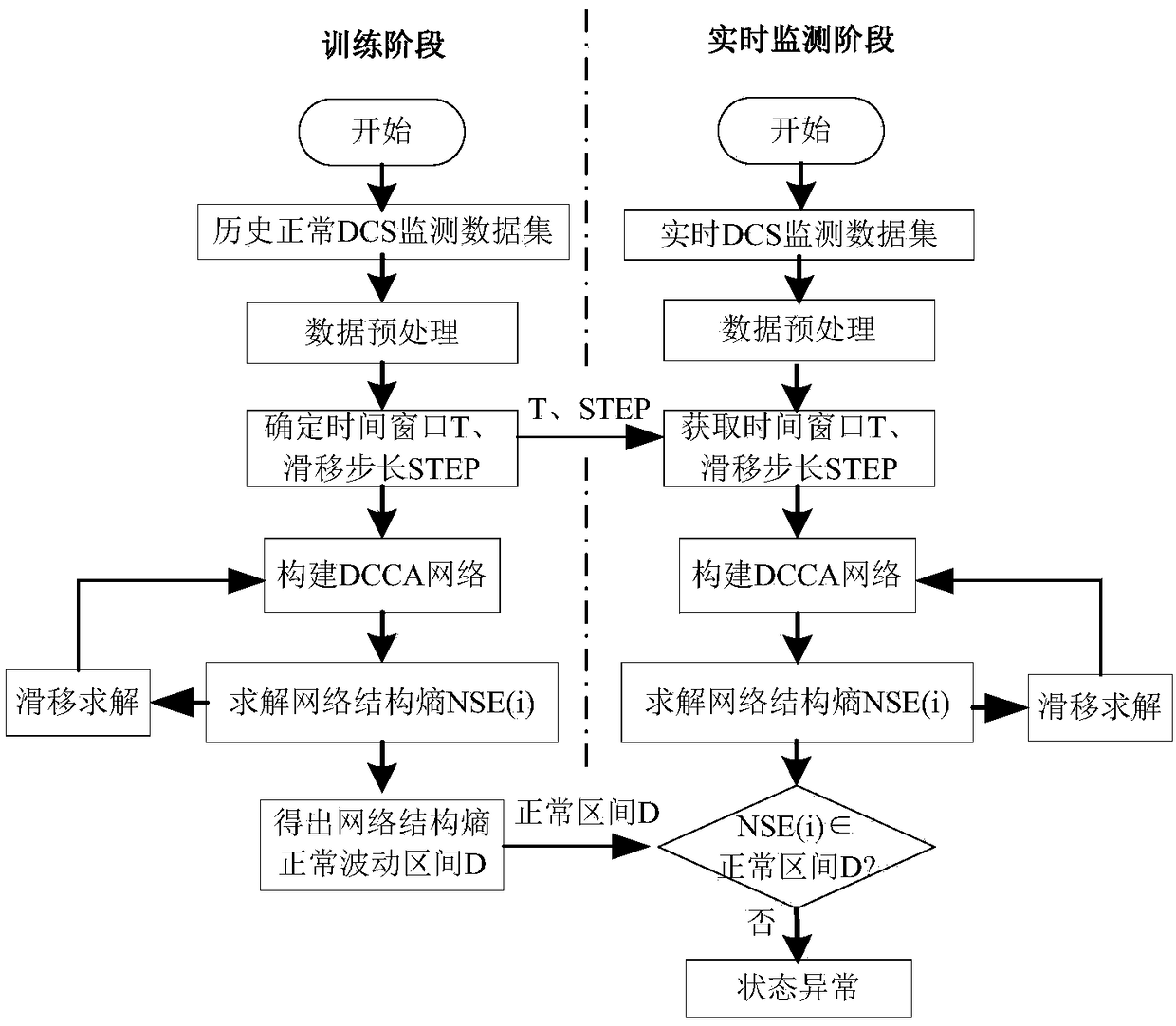

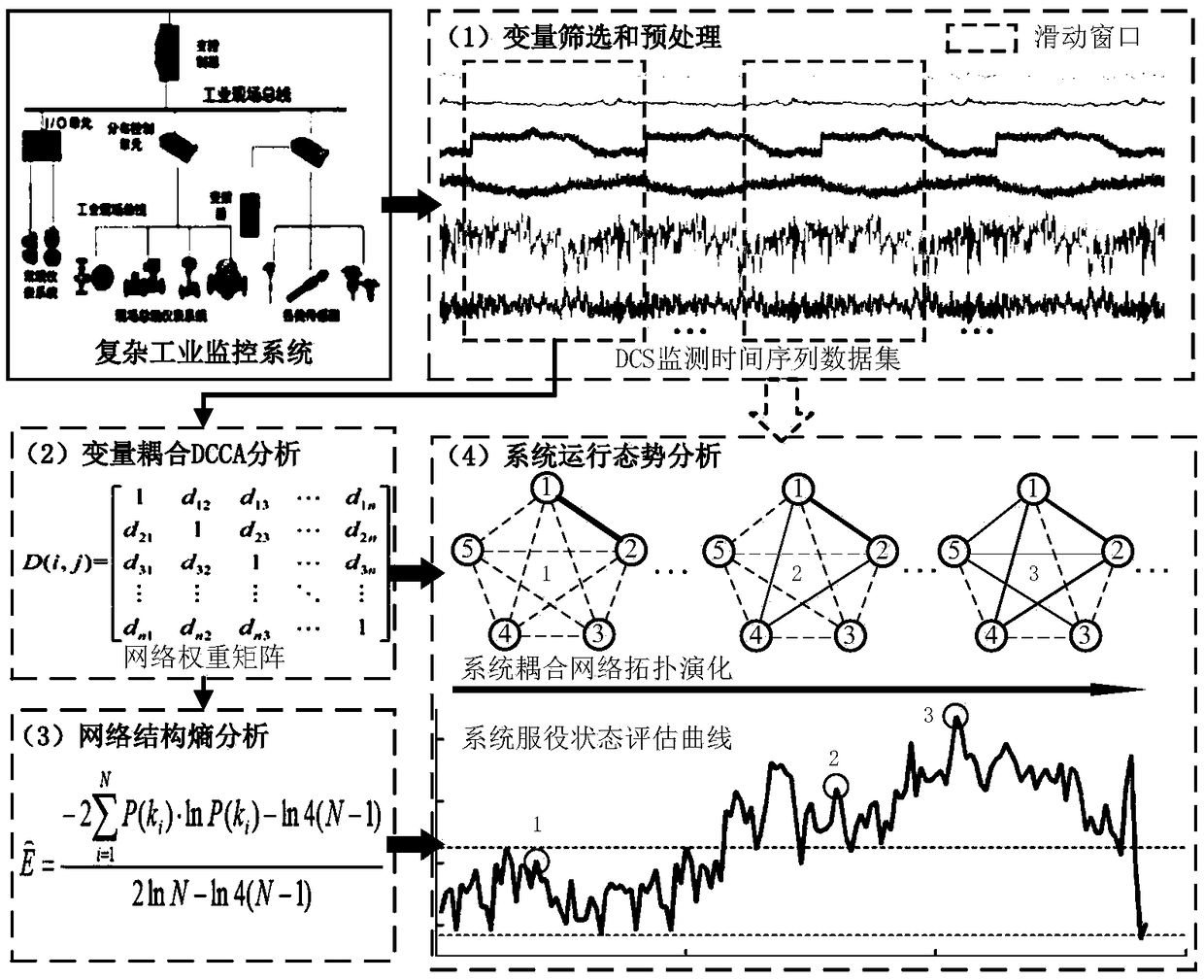

Method used

Image

Examples

Embodiment

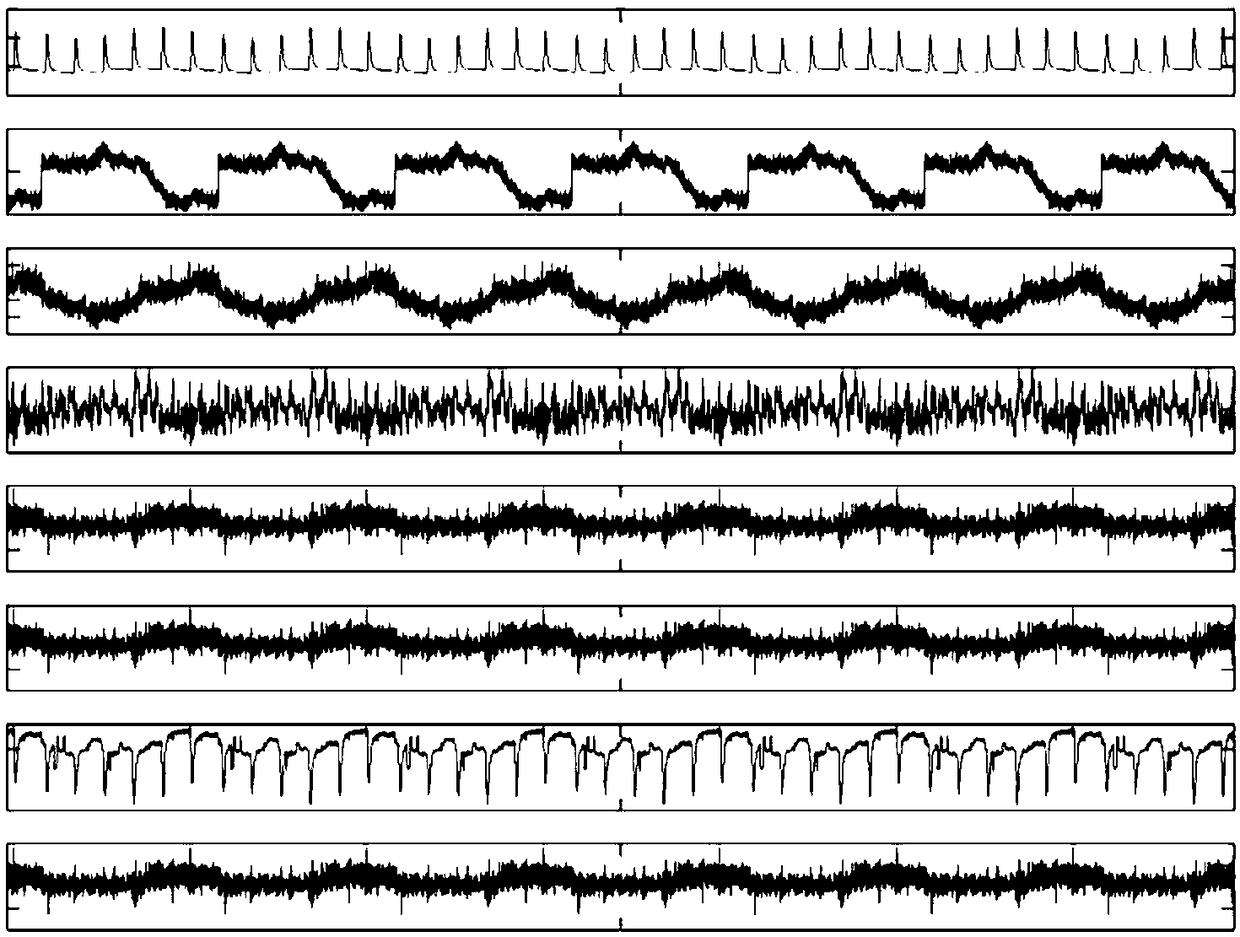

[0061] A complex electromechanical system including n elements samples the required production elements according to a specific time period and records them in system variables. After m sampling periods, the system has a total of m×n system variable data:

[0062] Step 1: Monitoring dataset preprocessing

[0063] First of all, the heterogeneous and heterogeneous data should be normalized, and each value in the variable X should be processed as follows:

[0064] X(i)=X(i) / mean(X)

[0065] Noise reduction processing is performed on the normalized data, and the method of wavelet packet noise reduction is adopted here.

[0066] Step 2: Selection of time window width

[0067] The quasi-period of the time series is analyzed by the algorithm to represent the change period of the time series. That is, when the length of the sequence is greater than the quasi-period of the variable, this time series can better reflect the characteristics of the variable.

[0068] Here we use the FF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com