Method of solving the balance problem of assembly line welding of body in white through improved particle swarm optimization algorithm

A technology for improving particle swarms and assembly lines, applied in computing, computing models, manufacturing computing systems, etc., and can solve problems such as unsatisfactory solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

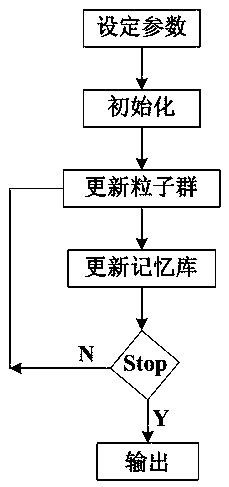

[0063] An improved particle swarm algorithm to solve the body-in-white welding assembly line balance problem. The method is to first define a function Φ(∙) to convert the position of the particle swarm into an assembly sequence, and give the constraint conditions for the first type of assembly line balance problem And the objective function, finally build an improved particle swarm algorithm to solve the white body welding assembly line balance problem.

[0064] The function Φ(∙) is defined as: from To The mapping is defined as ,Satisfy

[0065] (1) If , Then ;

[0066] (2) If And , Then ;

[0067] among them, , , , , , , , , i with j All represent the sequence number of the job element, k Represents the serial number of the assembly workstation, N Represents a collection of job elements, PS Represents the total number of particles, R Represents the set of real numbers, Represents a set of positive integers.

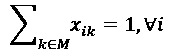

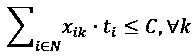

[0068] The constraints include:

[0069] (1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com