Prefabricated part production scheduling and worker configuration integrated optimization method, medium and equipment

A technology for production scheduling and prefabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

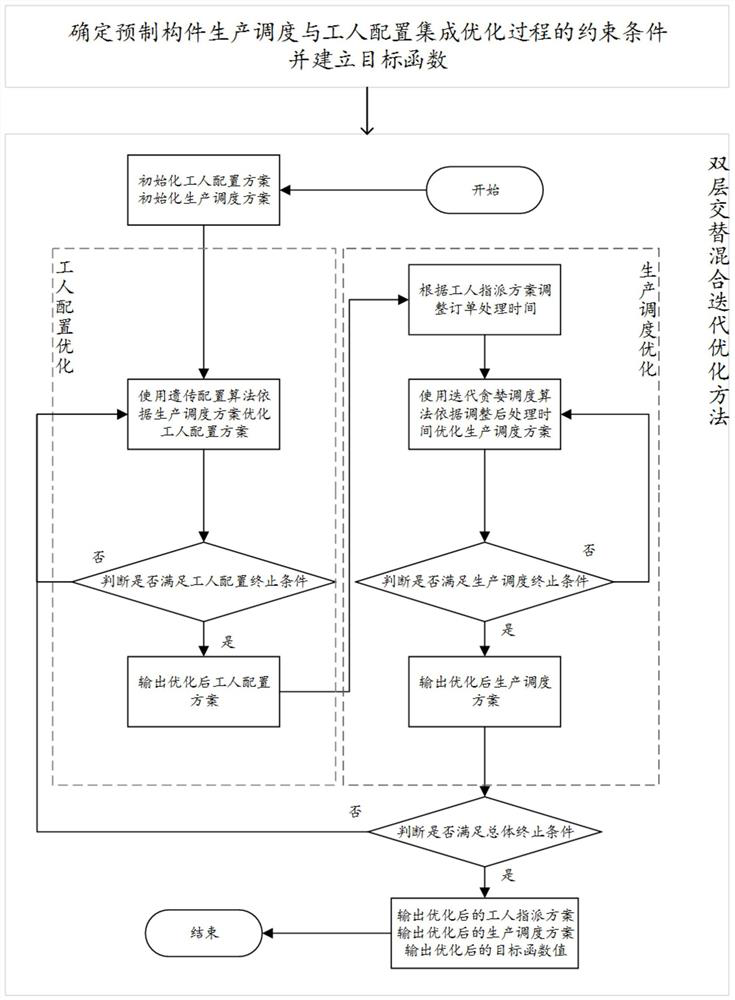

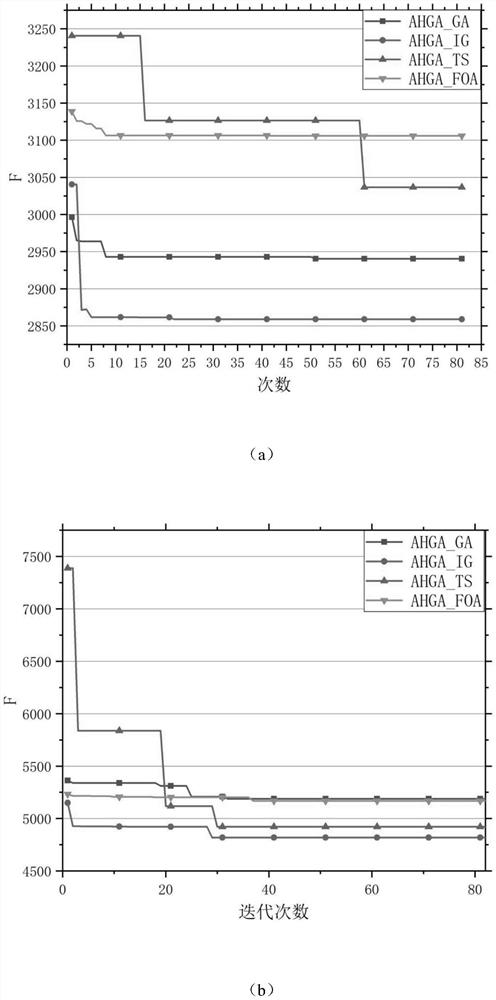

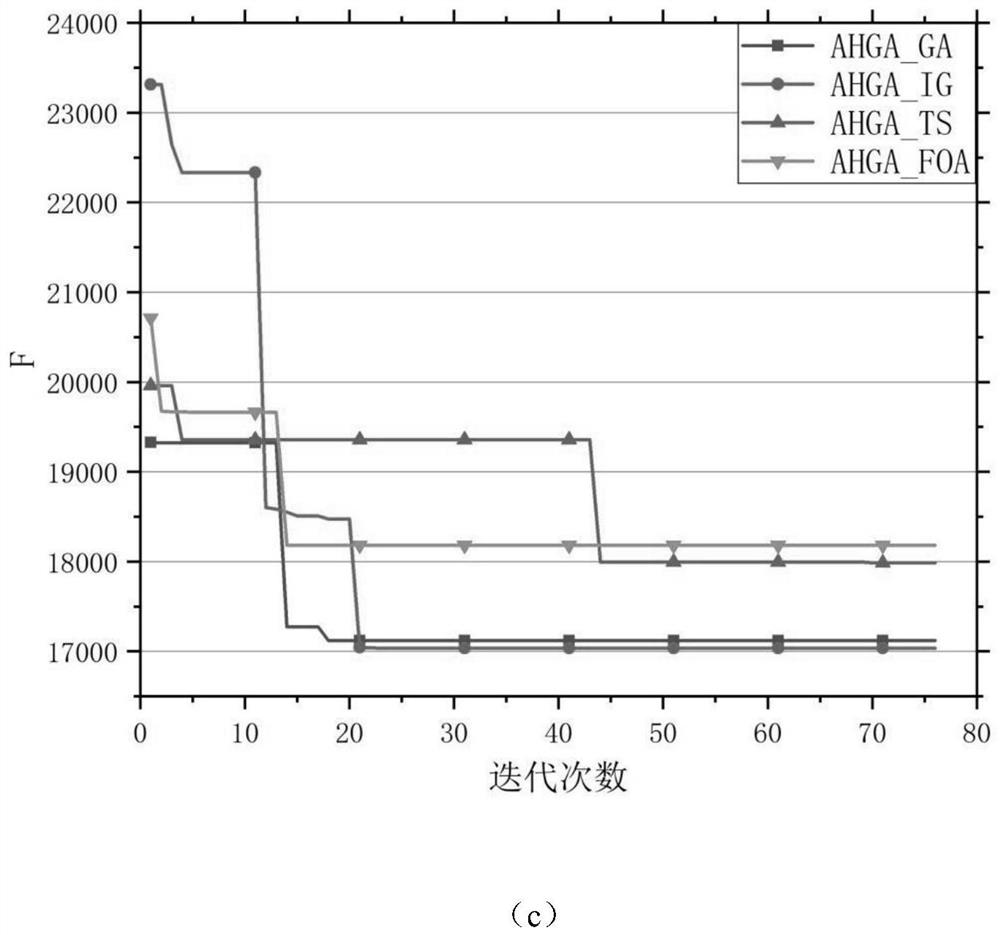

[0130] Integrating optimization method for production scheduling of prefabricated components and worker allocation based on alternating hybrid iterative search. In order to fully verify the performance of the method, hybrid genetic-tabu alternate search method (AHGA_TS), hybrid genetic alternate search method (AHGA_GA) and hybrid genetic-drosophila alternate search method (AHGA_FOA) were designed for comparative analysis. The AHGA_TS algorithm changes the destruction and reconstruction operations into taboo operations in the production scheduling layer; the AHGA_GA algorithm uses the classical genetic algorithm in the production scheduling layer; in the AHGA_FOA algorithm, the problem of the production scheduling layer is solved using the smell and visual search process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com